The IPC 4203B-2018 standard represents a critical specification in the flexible printed circuit board (flex PCB) industry, establishing comprehensive requirements for cover and bonding materials used in flexible electronic assemblies. As electronic devices continue to evolve toward more compact, lightweight, and flexible form factors, the importance of standardized materials and processes becomes paramount to ensuring reliability, manufacturability, and performance consistency across the industry.

Powered By EmbedPress

Background and Development

The Institute for Printed Circuits (IPC), now known as the Association Connecting Electronics Industries, developed IPC 4203B-2018 as an evolution of previous standards addressing the growing complexity and demanding applications of flexible circuits. This standard emerged from the need to address technological advances in materials science, manufacturing processes, and application requirements that were not adequately covered by earlier specifications.

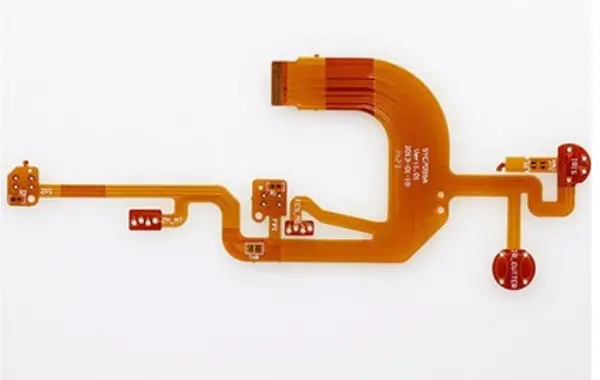

Flexible printed circuits have become increasingly prevalent in applications ranging from consumer electronics and automotive systems to aerospace and medical devices. The unique mechanical properties required for these applications—including the ability to bend, fold, and flex repeatedly without failure—necessitate specialized materials and rigorous testing protocols that differ significantly from those used in rigid PCB applications.

Scope and Application

IPC 4203B-2018 specifically addresses coverlay materials and adhesive systems used in the construction of flexible printed circuits. Coverlay serves as a protective layer that provides electrical insulation, environmental protection, and mechanical support to the underlying circuitry. The standard encompasses both adhesive-based coverlays and adhesiveless systems, recognizing the diverse manufacturing approaches employed across the industry.

The standard applies to single-sided and double-sided flexible circuits, as well as multi-layer flexible assemblies. It covers materials used in various application environments, from benign indoor conditions to harsh industrial and automotive environments where temperature extremes, chemical exposure, and mechanical stress are significant factors.

Material Classifications and Requirements

One of the fundamental aspects of IPC 4203B-2018 is its systematic classification of cover and bonding materials based on their thermal, mechanical, and electrical properties. The standard establishes multiple categories that allow designers and manufacturers to select appropriate materials based on specific application requirements.

Thermal performance classifications address the maximum operating temperatures that materials can withstand while maintaining their protective and mechanical properties. These classifications are particularly critical in applications such as automotive under-hood electronics or industrial control systems where elevated temperatures are routine operating conditions.

The mechanical property requirements encompass tensile strength, elongation characteristics, tear resistance, and dimensional stability. These properties are essential for applications involving repeated flexing, such as hinges in laptops, connections in automotive doors, or wearable electronic devices. The standard specifies test methods and acceptance criteria that ensure materials can withstand the mechanical stresses encountered in their intended applications.

Electrical property specifications include dielectric strength, surface resistivity, and dielectric constant values. These parameters are crucial for maintaining signal integrity and preventing electrical failures in high-frequency applications or densely packed circuit configurations.

Adhesive Systems and Bonding Requirements

The standard provides detailed specifications for adhesive systems used to bond coverlay materials to flexible circuit substrates. These specifications address both structural adhesives used for permanent bonds and removable systems designed for applications requiring access to underlying circuitry for repair or modification.

Adhesive performance requirements include shear strength, peel strength, and thermal cycling resistance. The standard recognizes that adhesive performance can be significantly affected by surface preparation, application conditions, and curing parameters, providing guidance on process control measures necessary to achieve consistent results.

Environmental resistance requirements for adhesive systems address exposure to humidity, temperature cycling, chemical exposure, and UV radiation. These specifications ensure that bonded assemblies maintain their integrity throughout their intended service life, even when exposed to challenging environmental conditions.

Testing Methodologies and Quality Assurance

IPC 4203B-2018 establishes comprehensive testing protocols that enable manufacturers to verify material compliance and end-users to qualify materials for specific applications. The standard references numerous ASTM, IEC, and other IPC test methods while also defining specific procedures tailored to flexible circuit applications.

Mechanical testing procedures include bend radius testing, which determines the minimum radius to which a flexible circuit can be bent without damaging the coverlay or underlying circuitry. This testing is particularly important for applications involving repeated flexing, as it helps predict service life and reliability.

Thermal testing encompasses both steady-state temperature exposure and thermal cycling tests. These procedures evaluate material stability, dimensional changes, and property retention under various thermal conditions. The standard specifies conditioning periods, temperature profiles, and measurement techniques that ensure reproducible and meaningful results.

Electrical testing procedures address insulation resistance, dielectric strength, and surface resistivity measurements. These tests are performed both on virgin materials and after various environmental exposures to verify that electrical properties remain within acceptable limits throughout the material’s service life.

Manufacturing Process Considerations

The standard acknowledges that material performance is intimately linked to manufacturing processes and provides guidance on process parameters that affect final product quality. Lamination temperature and pressure profiles, adhesive application methods, and surface preparation requirements are addressed to help manufacturers achieve consistent results.

Process control recommendations include statistical process control methods, inspection criteria, and documentation requirements. These elements are essential for maintaining quality in production environments and for troubleshooting when quality issues arise.

The standard also addresses handling and storage requirements for cover and bonding materials, recognizing that improper handling can significantly affect material performance. Shelf life specifications, storage environmental conditions, and handling procedures help ensure that materials maintain their specified properties from receipt through final application.

Industry Impact and Adoption

Since its publication, IPC 4203B-2018 has become widely adopted across the flexible circuit industry, providing a common framework for material specification, qualification, and procurement. The standard has facilitated improved communication between material suppliers, circuit manufacturers, and end-users by establishing common terminology and test methods.

The standardization has also contributed to improved product reliability by ensuring that materials used in flexible circuits meet minimum performance requirements appropriate for their intended applications. This has been particularly beneficial in high-reliability applications such as aerospace and medical devices, where material failures can have significant consequences.

Future Considerations and Evolution

As technology continues to advance, the requirements placed on flexible circuit materials continue to evolve. Emerging applications such as foldable displays, wearable sensors, and Internet of Things devices present new challenges that may require updates to existing standards or development of new specifications.

The increasing emphasis on environmental sustainability is also influencing material selection and specification requirements. Future revisions of the standard may need to address recycling considerations, bio-based materials, and reduced environmental impact manufacturing processes.

Additionally, the trend toward higher frequency electronic applications is placing new demands on the electrical performance of coverlay materials, particularly in terms of signal integrity and electromagnetic interference considerations. These evolving requirements will likely drive future updates to the standard.

Conclusion

IPC 4203B-2018 represents a comprehensive and mature standard that addresses the critical requirements for cover and bonding materials in flexible printed circuits. By providing detailed specifications, test methods, and process guidance, the standard enables the reliable manufacture of flexible circuits for a wide range of applications. Its adoption has contributed significantly to improved product quality, enhanced reliability, and more efficient communication throughout the supply chain. As the flexible electronics industry continues to evolve, this standard will undoubtedly continue to serve as a foundational reference while adapting to meet emerging technological challenges and requirements.

Related posts:

- IPC-2226: Sectional Design Standard for High Density Interconnect (HDI) Printed Boards

- IPC-A-600 Standard: Acceptability of Printed Boards – Training, Certification & Class 2/3 Requirements (Latest IPC-600J/K)

- Quick Turn Flex PCB Manufacturing – Fast Delivery 1-10 Layer Flexible Circuits

- KiCad Flex PCB Design Guide: Creating Flexible Circuits with Open-Source Tools