Designing a safe, efficient, and compact inverter is a crucial task for engineers and electronics enthusiasts alike. Inverters are essential components in various applications, from renewable energy systems to industrial equipment, and their performance can significantly impact the overall system’s reliability and energy efficiency. In this comprehensive article, we will explore the key considerations and best practices for designing an inverter that meets these essential criteria.

Understanding the Fundamentals of Inverter Design

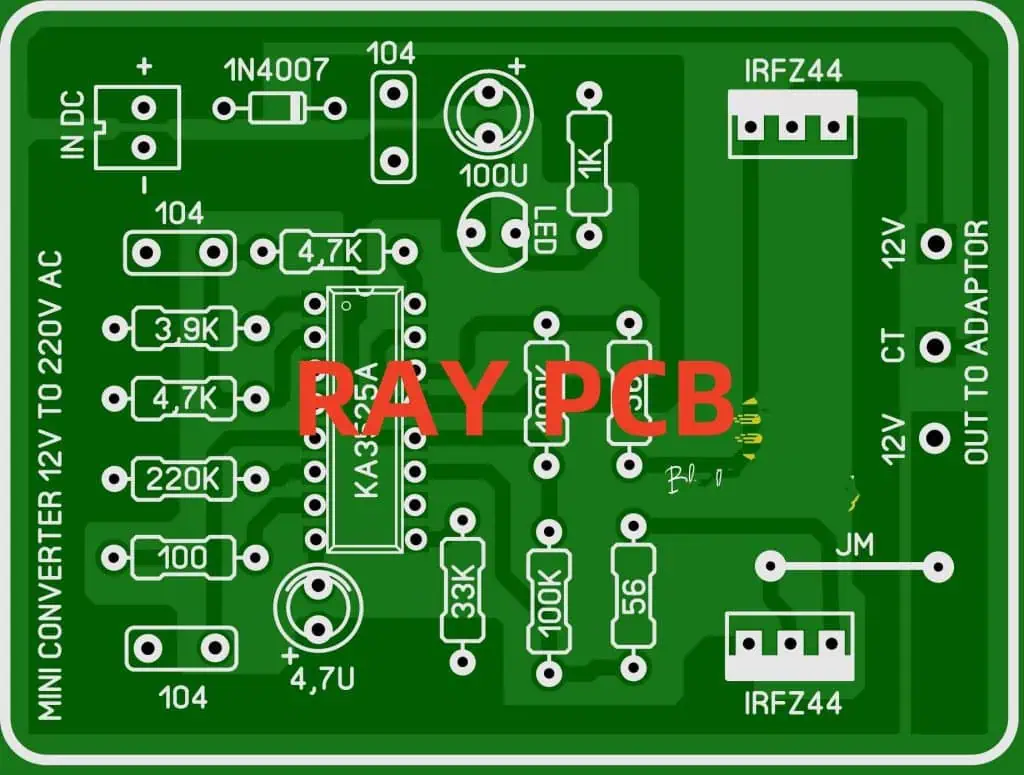

An inverter is a power electronic device that converts direct current (DC) to alternating current (AC). The primary function of an inverter is to transform the voltage and current characteristics of the input DC power to match the requirements of the AC load. Inverters can be classified into different types based on their input voltage, output voltage, and power rating.

In the context of safe, efficient, and compact inverter design, the following factors play a crucial role:

- Safety Considerations:

- Overcurrent and overload protection

- Thermal management and heatsink design

- Isolation and grounding requirements

- Compliance with safety standards (e.g., UL, IEC, NEC)

- Efficiency Optimization:

- Selection of high-efficiency semiconductor devices

- Minimizing power losses in various components

- Optimization of switching frequency and modulation techniques

- Thermal management and cooling system design

- Compact Design:

- Miniaturization of components and circuit layout

- Utilization of high-density packaging and integration techniques

- Optimization of heat dissipation and thermal management

Safety Considerations in Inverter Design

Safety is of paramount importance when designing an inverter, as it directly impacts the reliability and longevity of the system. Let’s delve into the key safety aspects that should be addressed during the design process.

Overcurrent and Overload Protection

Inverters are susceptible to overcurrent and overload conditions, which can lead to component failure and even fire hazards. To mitigate these risks, the inverter design must incorporate effective overcurrent and overload protection mechanisms, such as:

- Circuit Breakers: Incorporating circuit breakers that can quickly interrupt the flow of current in the event of an overload or short circuit.

- Fuses: Using fast-acting fuses to protect the inverter’s internal components from excessive current.

- Current Limiting Circuitry: Implementing current limiting circuitry to prevent the inverter from delivering more current than the system can safely handle.

Thermal Management and Heatsink Design

Inverters generate heat during operation due to power losses in various components, such as semiconductor devices, control circuitry, and passive components. Effective thermal management is crucial to ensure the safe and reliable operation of the inverter. This includes:

- Heatsink Design: Designing an efficient heatsink that can effectively dissipate the heat generated by the inverter’s components.

- Air or Liquid Cooling: Incorporating active cooling systems, such as fans or liquid cooling, to enhance heat dissipation.

- Thermal Monitoring: Implementing temperature sensors and control algorithms to monitor and manage the inverter’s thermal performance.

Isolation and Grounding Requirements

Proper isolation and grounding are essential for the safety of the inverter and the connected system. This includes:

- Input-Output Isolation: Ensuring adequate isolation between the input DC side and the output AC side to prevent the transfer of dangerous voltages.

- Grounding and Bonding: Establishing a robust grounding and bonding system to protect against electric shock and ensure the integrity of the system’s electrical safety.

- Compliance with Standards: Designing the inverter to meet the requirements of relevant safety standards, such as UL, IEC, and NEC, to ensure the overall system’s safety and compliance.

Efficiency Optimization in Inverter Design

Efficiency is a critical aspect of inverter design, as it directly impacts the energy consumption, operating costs, and environmental impact of the system. Here are the key considerations for optimizing the efficiency of an inverter:

Selection of High-Efficiency Semiconductor Devices

The choice of semiconductor devices, such as power transistors and diodes, plays a significant role in the overall efficiency of the inverter. Factors to consider include:

- Switch Selection: Selecting high-efficiency semiconductor switches, such as MOSFETs or IGBTs, that exhibit low on-state resistance and switching losses.

- Diode Selection: Choosing low-loss diodes, such as Schottky or ultra-fast recovery diodes, to minimize conduction and switching losses.

Minimizing Power Losses in Various Components

Reducing power losses in the inverter’s various components, such as the input filter, output filter, and control circuitry, can significantly improve the overall efficiency. Strategies include:

- Optimizing Filter Design: Designing the input and output filters to minimize conduction and switching losses.

- Minimizing Winding Losses: Optimizing the design of transformers and inductors to reduce copper and core losses.

- Reducing Capacitor Losses: Selecting low-loss capacitors and minimizing the number of capacitors used in the inverter circuit.

Optimization of Switching Frequency and Modulation Techniques

The switching frequency and modulation technique employed in the inverter can have a significant impact on efficiency. Factors to consider include:

- Switching Frequency: Selecting an optimum switching frequency that balances switching losses and filter requirements.

- Modulation Techniques: Utilizing advanced modulation techniques, such as PWM (Pulse-Width Modulation) or SVM (Space Vector Modulation), to minimize harmonic distortion and improve efficiency.

Thermal Management and Cooling System Design

Effective thermal management is crucial for maintaining the inverter’s efficiency. This includes:

- Heatsink Design: Designing an efficient heatsink that can effectively dissipate the heat generated by the inverter’s components.

- Active Cooling Systems: Incorporating active cooling systems, such as fans or liquid cooling, to enhance heat dissipation and maintain optimal operating temperatures.

- Thermal Monitoring and Control: Implementing temperature sensors and control algorithms to monitor and manage the inverter’s thermal performance, ensuring that it operates within the optimal temperature range.

Compact Design of Inverters

Compact inverter design is essential in applications where space is limited, such as in portable electronics, renewable energy systems, or industrial equipment. Achieving a compact design requires optimization of both the physical layout and the integration of components. Let’s explore the key strategies for compact inverter design:

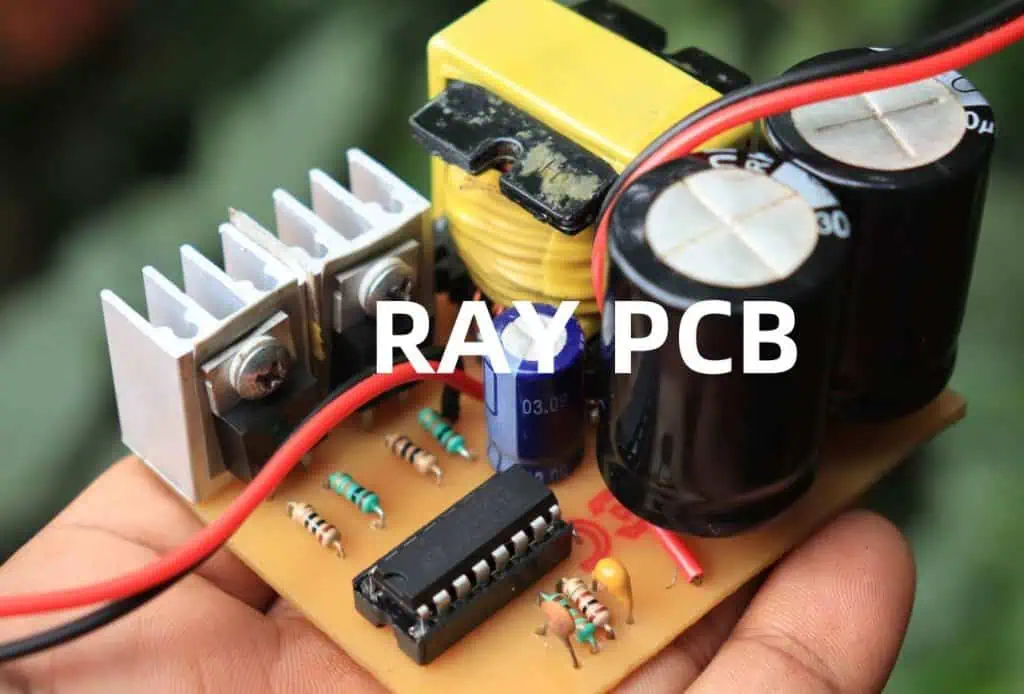

Miniaturization of Components and Circuit Layout

Reducing the physical size of the inverter’s components and optimizing the circuit layout can significantly contribute to a compact design. Strategies include:

- Component Selection: Choosing compact, high-density components, such as surface-mount devices (SMDs) and integrated circuits (ICs), to minimize the overall footprint.

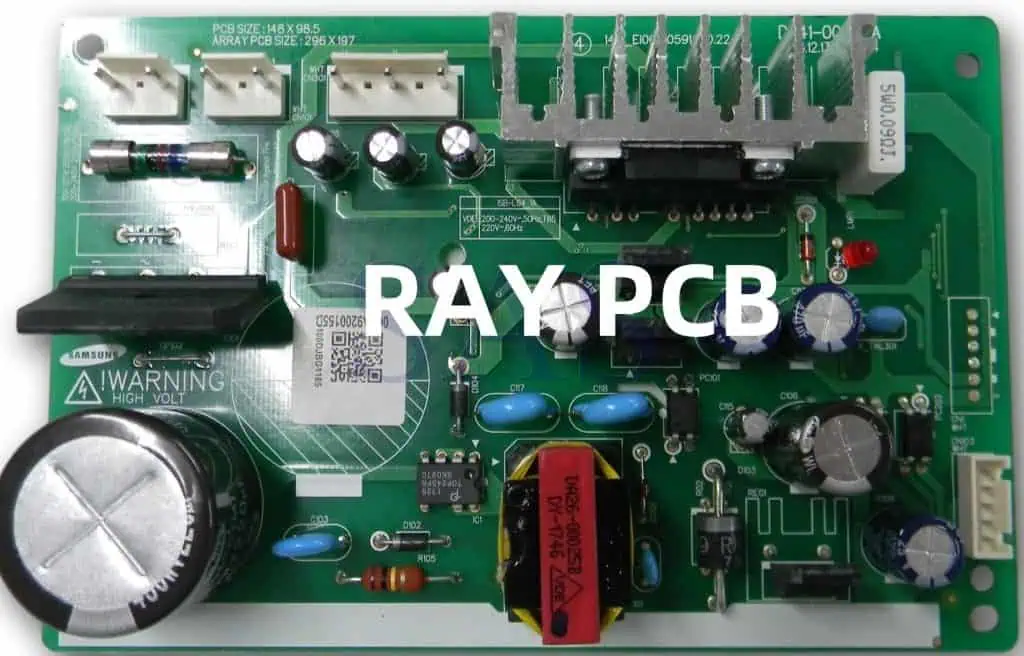

- Circuit Layout Optimization: Employing techniques like high-density PCB design, multilayer boards, and component placement optimization to minimize the overall size of the inverter.

Utilization of High-Density Packaging and Integration Techniques

Advanced packaging and integration techniques can further enhance the compactness of the inverter design. These include:

- Power Modules: Integrating multiple power semiconductor devices, control circuitry, and other components into a single power module to reduce the overall size and complexity of the inverter.

- System-on-Chip (SoC) Integration: Integrating the inverter’s control, driver, and power conversion functions into a single integrated circuit (IC) to achieve a highly compact and integrated design.

- Multifunctional Components: Utilizing components that combine multiple functions, such as integrated gate drivers or multiphase converters, to reduce the overall component count and footprint.

Optimization of Heat Dissipation and Thermal Management

Effective thermal management is crucial in compact inverter designs, as the limited physical space can challenge the ability to dissipate heat efficiently. Strategies for optimizing heat dissipation and thermal management include:

- Heatsink Integration: Designing the heatsink as an integral part of the inverter’s physical structure to maximize heat dissipation while maintaining a compact form factor.

- Thermal Interface Materials: Using high-performance thermal interface materials, such as thermal greases or phase-change materials, to improve the thermal coupling between components and the heatsink.

- Airflow Optimization: Optimizing the airflow and cooling system design to efficiently remove heat from the inverter’s critical components, even in a compact enclosure.

Case Study: Designing a Compact, High-Efficiency Inverter for a Solar PV System

To illustrate the practical application of the principles discussed, let’s consider a case study of designing a compact, high-efficiency inverter for a solar photovoltaic (PV) system.

System Requirements

- Input Voltage: 48 VDC (from solar PV array)

- Output Voltage: 230 VAC, 50 Hz

- Power Rating: 5 kW

Safety Considerations

- Overcurrent and overload protection: Implement a circuit breaker and fast-acting fuses to protect against overcurrent and overload conditions.

- Thermal management: Design a heatsink with a high-efficiency air cooling system to dissipate the heat generated by the inverter’s components.

- Isolation and grounding: Ensure proper input-output isolation and establish a robust grounding system to meet safety standards.

Efficiency Optimization

- Semiconductor device selection: Choose high-efficiency MOSFETs and Schottky diodes to minimize conduction and switching losses.

- Input and output filter design: Optimize the filter design to reduce conduction and switching losses.

- Switching frequency and modulation: Employ a PWM modulation technique with a switching frequency of 20 kHz to balance efficiency and filter requirements.

- Thermal management: Integrate the heatsink design with the overall inverter layout to efficiently dissipate heat.

Compact Design Strategies

- Component miniaturization: Utilize SMD components and high-density PCB design to minimize the physical footprint.

- Integrated power module: Employ a compact power module that integrates the power semiconductor devices, gate drivers, and control circuitry.

- Heatsink integration: Design the heatsink as an integral part of the inverter’s enclosure to maximize heat dissipation while maintaining a compact form factor.

- Airflow optimization: Optimize the cooling system design to ensure efficient heat removal from the critical components, even in a compact enclosure.

By implementing the safety, efficiency, and compactness principles discussed in this article, the resulting inverter design for the solar PV system would be a compact, high-efficiency, and safe solution, suitable for integration into a space-constrained renewable energy application.

FAQ (Frequently Asked Questions)

- What are the key considerations for designing a safe inverter?

- Overcurrent and overload protection

- Thermal management and heatsink design

- Isolation and grounding requirements

- Compliance with safety standards (e.g., UL, IEC, NEC)

- How can I optimize the efficiency of an inverter design?

- Select high-efficiency semiconductor devices

- Minimize power losses in various components

- Optimize switching frequency and modulation techniques

- Implement effective thermal management and cooling systems

- What strategies can be used to achieve a compact inverter design?

- Miniaturize components and optimize circuit layout

- Utilize high-density packaging and integration techniques

- Optimize heat dissipation and thermal management

- How does the selection of semiconductor devices impact the efficiency of an inverter?

- The choice of power transistors (e.g., MOSFETs, IGBTs) and diodes with low on-state resistance and switching losses can significantly improve the overall efficiency of the inverter.

- What are the benefits of using a power module in a compact inverter design?

- Power modules integrate multiple power semiconductor devices, control circuitry, and other components into a single package, reducing the overall size and complexity of the inverter design.