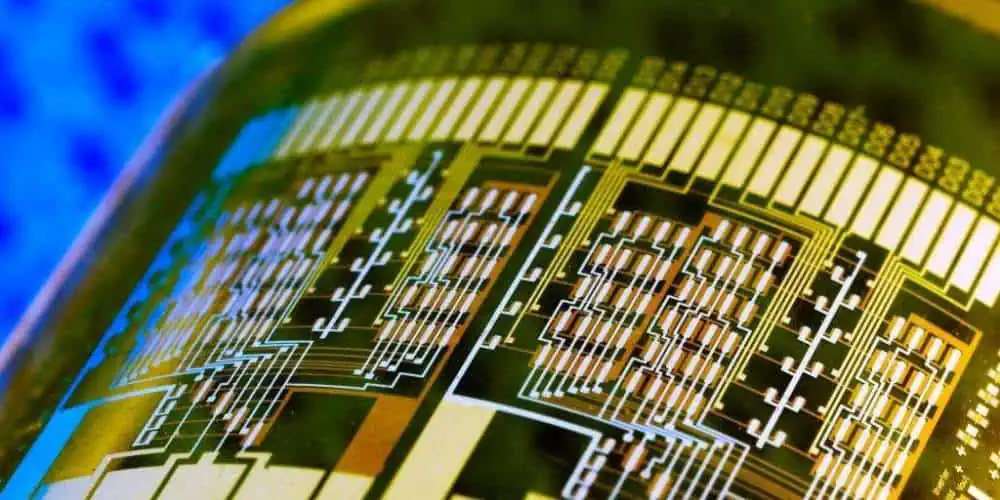

Imagineering PCB is a term that describes creating custom-designed printed circuit boards (PCBs). PCBs should adhere to strict specifications by combining engineering with imaginative thinking.

We can design the circuit board using sophisticated software tools and produce the actual circuit board via manufacturing. In addition to designing unique circuits not commonly available in commercially available PCBs, Imagineering PCB may also entail this.

Imagineering PCB companies can offer various services, such as design, layout, prototype, and manufacture. Also, they could collaborate with clients to create unique PCBs that address certain issues or demands.

The benefits of Imagineering PCB

Imagineering PCB is a potent tool that combines engineering and imagination to produce specially designed printed circuit boards (PCBs) that adhere to certain specifications. As a result, Imagineering PCB has various advantages, from increased performance and usefulness to more customization and flexibility. We’ll look at some of the significant benefits of Imagineering PCB in this article and how they promote innovation and development in electronics manufacturing.

Custom circuits

Imagineering PCB’s capacity to design bespoke circuits that are not commonly available in off-the-shelf PCBs is one of its main advantages. With the aid of Imagineering PCB, designers and engineers can produce one-of-a-kind, cutting-edge circuits suited to particular applications, enhancing performance and functionality. Imagineering PCB may minimize power consumption, boost processing speed, and enhance signal integrity, among other advantages, by developing bespoke circuits. This customization may be beneficial in sectors like aerospace, medical technology, and industrial automation, where ordinary PCBs might not be able to satisfy unique needs.

Unique designs

The capacity to produce original and cutting-edge designs that can aid in differentiating items in the marketplace is another advantage of Imagineering PCB. We can make products that stand out from the competition. They can provide a better user experience with the aid of Imagineering PCB. This is particularly relevant in consumer electronics, where product success depends on design and aesthetics. Designers may produce goods that are not only useful but also aesthetically pleasing and engaging by employing Imagineering PCB.

Flexibility and adaptability

Moreover, Imagineering PCB provides more adaptability and flexibility during the design process. Imagineering PCB enables simple customization and circuit design change, unlike off-the-shelf PCBs, which are made for specific purposes and cannot be readily modified. This flexibility may be beneficial as design changes, and iterations are frequent in product development. With the aid of Imagineering PCB, designers can rapidly alter circuit designs to satisfy shifting specifications, hastening the creation of new products and their time to market.

Efficiency

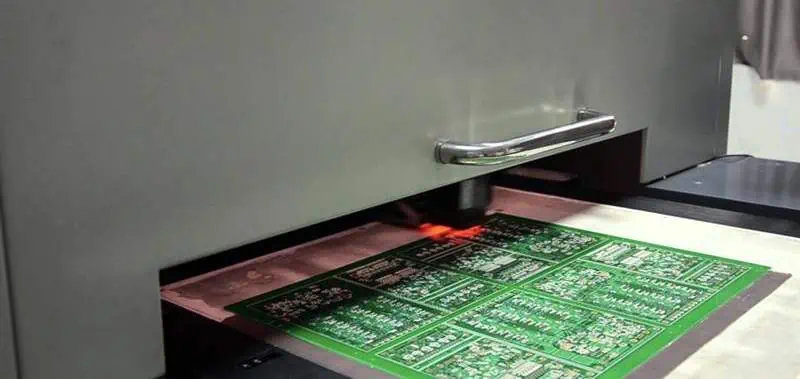

The capacity to lower costs and increase production efficiency is another advantage of Imagineering PCB. Imagineering PCB may assist in lowering component counts, minimizing waste, and raising production yields by developing unique circuits tailored for specific applications. As a result, Imagineering PCB can be a cost-effective alternative for many applications due to lower prices and increased manufacturing volumes.

Innovation

With these advantages, Imagineering PCB is advancing various sectors via innovation. Imagineering PCB, for instance, is being utilized to create cutting-edge virtual and augmented reality technologies, which call for high-performance and unique circuit designs. Furthermore, advanced medical gadgets like implanted sensors and remote monitoring and diagnostics tools are products of Imagineering PCB. In addition, Imagineering PCB is used in the aerospace industry to design compact, high-performance circuits for satellites, spaceships, and other types of spacecraft.

What skills are necessary for Imagineering PCB?

A mix of technical expertise and original thought is necessary for the complicated, diverse area of Imagineering PCB. The engineers and designers who work in Imagineering PCB need to have a thorough grasp of electronics, PCB design, and manufacturing procedures, as well as creative thinking and idea generation skills. The following are some of the particular abilities necessary for PCB imaging:

Electronics Design:

An in-depth knowledge of electronics design, including digital and analog circuit design, signal processing, and power management, is required of engineers and designers working in Imagineering PCB. In addition, they need skills in drawing and analyzing schematics and designing circuit boards. They must adhere to strict specifications and troubleshoot problems while designing.

PCB Design:

An understanding of PCB design, including an understanding of PCB layout, component placement, and routing, is also necessary for Imagineering PCB. Designers must create digital circuit board designs using software tools. It ensures that the layout is optimum for the particular application and that they can produce the board quickly and accurately.

Manufacturing Processes:

Understanding manufacturing procedures are also necessary for Imagineering PCB. The materials used in PCB fabrication and the tolerances and specifications for various manufacturing methods must be all friendly to engineers and designers.

Creativity:

Imagineering PCB demands both technical expertise and creative and original thought. Engineers and designers must think creatively and develop fresh approaches to solving challenging issues. They also need to push the limits of what is practical in electrical design.

Communication and Collaboration:

Working with a group of engineers, designers, and other stakeholders is a common part of the collaborative process known as Imagineering PCB. As a result, effective communication and teamwork abilities are crucial for success in this industry. Engineers and designers need to collaborate with others and be receptive to criticism and suggestions from their peers.

What industries use Imagineering PCB?

Printed circuit boards that are specially to satisfy specific needs are helpful in various sectors. These are a few examples of industries that often employ Imagineering PCB:

Aerospace:

The aerospace sector needs Circuit boards that survive severe temperatures and harsh conditions. Imagineering PCB designs and produces custom PCBs for aerospace applications, such as satellites, spacecraft, and avionics systems.

Medical Devices:

Custom PCBs created to fulfill particular specifications for size, power consumption, and signal processing are frequently necessary for medical devices. Custom circuits for various medical devices, such as pacemakers, implantable devices, and diagnostic equipment, are made using Imagineering PCB.

Industrial Automation:

Custom-designed PCBs are essential for managing and controlling robots, automated manufacturing, and other automated systems in the industrial automation sector. PCBs tailored for certain industrial uses, such as high-temperature conditions, vibration, and shock resistance, are designed and produced using Imagineering PCB.

Consumer Electronics:

Companies that make consumer electronics employ Imagineering PCB to build circuit boards specifically for smartphones, tablets, wearables, and other gadgets. By enhancing performance, these bespoke PCBs enable manufacturers to distinguish their goods in a fiercely competitive market.

Automotive:

For usage in bespoke PCBs for car electronics, including safety systems, infotainment systems, and powertrain control systems, the automotive industry employs Imagineering PCB. These customized PCBs must endure extremely high temperatures and severe conditions and adhere to strict size and power specifications.

Summary

Imagineering PCB is a significant component of contemporary electronics design and production.

The Imagineering PCB is essential for innovation and advancement in electronics design and production. Imagineering PCB enables designers and engineers to build unique circuits that adhere to strict specifications. It results in increased performance, functionality, and design. As a result, Imagineering PCB is advancing technology and enhancing the goods and experiences.

Imagineering PCB calls for a special mix of technical and artistic abilities and the capacity for teamwork and good communication. These abilities enable engineers and designers to produce bespoke circuit boards that adhere to detailed specifications and promote innovation in electronic manufacturing.

Last, Imagineering PCB is helpful in various sectors where specialized printed circuit boards are necessary to satisfy demands. These demands include performance, size, power consumption, and environmental considerations.