Two components of a PCB that are crucial in its structure are resistors and components. Their roles are essential to developing the finest industrial PCBs for safe and seamless electronics performance on all counts. If we rely on faulty components, including resistors and capacitors, there are more chances of complete PCB failure.

We will see how we can pick the suitable component for the sustenance of our PCBs through this post. After this, you will be able to select the appropriate capacitors and resistors for your PCB projects successfully.

Selecting resistor components for the PCB

First, let’s see how we can choose suitable resistors for our PCBs. As you know, the purpose of a resistor is to oppose the current flow through a circuit or a setup. Therefore, we can use them in a PCB to regulate the current flow easily. Let’s see what factors you need to evaluate your options for picking the right resistor!

· Tolerance level:

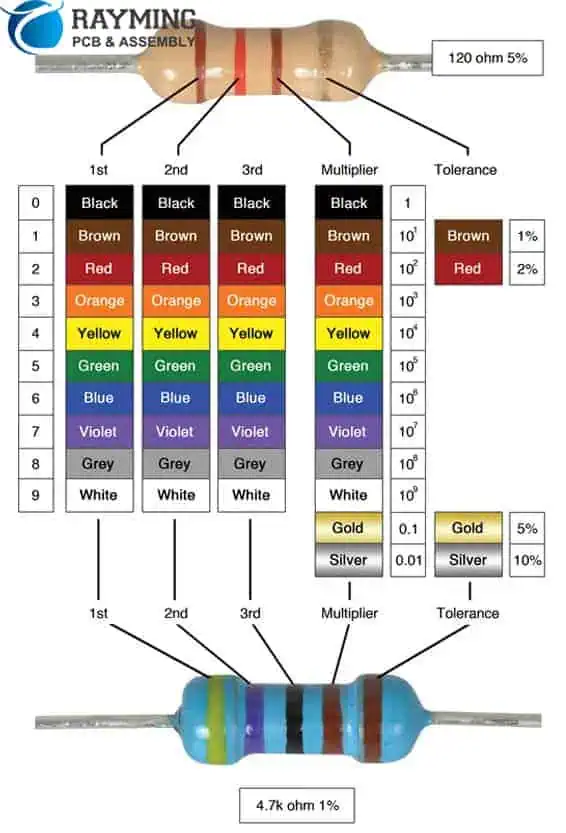

Tolerance is an important factor for resistors. The best resistors are those having tolerances of 0.1%, 5%, and 10%. The reason is that we can easily work with these tolerances without facing any complications. Some experts even compare these three specific tolerances and emphasize using a tolerance of 0.1% for the projects. Some resistors that have high tolerances are cheaper than others.

· Power level:

There is no doubt that some resistors are not good in terms of power level. Therefore, for PCBs, we need to rely on powerful resistors that can perform their job under unfavorable situations easily. Inappropriate resistors in the aspect of power level can directly damage the PCB as well. It is always better to determine the power level of the resistors beforehand when buying them.

· Temperature:

The temperature range of resistors also differs. We need such resistors that can easily tolerate high temperatures if PCBs are working in heat-sensitive applications and devices. It is better to see what type of temperature range you need by comparing the resistors with your applications. It will protect your PCBs from undergoing heat damage and will enhance their longevity as well.

· Resistance:

Another important factor is resistance. The best resistors in this aspect are those with 1-kilo ohms. These can make PCBs more efficient in terms of performance and durability. Make sure to check the resistance before picking the resistors.

Selecting capacitor components for the PCB

Now it’s time to see what factors make a good capacitor. Carefully follow the section below to see how you can never go wrong with the capacitor selection each time.

· Tolerance:

Every capacitor has a different tolerance, and good capacitors are those that come with a maximum 20% tolerance. Well, if you find one with a 10% tolerance, it is good enough. It is better to check the tolerance of capacitors to avoid all sorts of complications easily.

· Capacitance:

The default and suitable capacitance of a standard capacitor is 10uF which is why we need to rely on such capacitors on all counts. Chances of failure and poor performance with such a capacitance are fewer.

· Voltage level:

The capacitors are not good at tolerating high temperatures due to voltage changes. Therefore, you need to see what type of capacitor suits your projects the best to avoid failure and risks. The best way to do this is to seek professional help to avoid confusion.

· Temperature range:

The capacitors that can tolerate up to 85 degrees have an optimum temperature range, and therefore, experts always emphasize their utilization as well. Make sure to use such a capacitor to drive positive results.

Factors to Consider while Selecting Resistor and Capacitor Components for PCB Design

You don’t want to ruin your projects by relying on faulty resistors and capacitors. Therefore, to give you a certain direction, we have compiled some effective tips in this section for you. Below are some handy considerations that can greatly help you in this regard.

- Component Values: The component values like current needs, voltage changes, time constraints, and impedance are important to determine when it comes to capacitors and resistors because these are variable factors. Therefore always fix them as per your projects for better results.

- Identify Tolerance: Two factors, including power rating and tolerance, are important for the fine performance of resistors and capacitors. Tolerances for resistors are optimum if you’re using 1%, 5%, and 10%. Tolerances for capacitors work best in 5% and 10% only. Power rating is important to determine because, through this, we can execute damage control and seamless power dissipation with it to a large extent.

- Select the Right Size: It is better to understand the importance of package size since these are different for resistors and capacitors. First, check PCB designs and see which components are a perfect fit as per your designs. Inappropriate package sizes can easily ruin PCBs through short circuits. Experts believe that going with SMD components, in this case, is beneficial.

- Temperature & Environmental Requirements: Not all resistors and capacitors are good with temperature regulation and preventing environmental damage. You happen to work on some applications that need extra features like moisture absorption and vibration. Therefore always choose the types that are suitable for your projects.

- Voltage & Current: Another important tip here is to determine the voltage and current ratings. It is crucial that resistors and capacitors of your choice work under a fixed limit of current and voltage. If these will cross this threshold, it can lead your PCBs to complete failure.

- Signal Frequency: When it comes to the selection of PCB components like resistors and capacitors, signal frequency and capacitor ESR are crucial. ESR is important for RF applications that operate on a high frequency. It prevents signal loss and also makes the setup efficient.

- Research Specialized Components: There are some special projects that need advanced components like high voltage capacitors and some technical components having advanced filtering attributes. Due to this reason, it is better to carefully determine your needs and see if you actually need such specialized components or not.

- Cost & Availability: Some capacitors and resistors having advanced features are costly. There is always a chance that these might not always be readily available in the market. Therefore, make sure to look for suitable and affordable components to not spend extra on your projects.

- Check Supplier Datasheets: Another great tip for you in this regard is to check manufacturer datasheets. These are important and give you a clear idea about what type of resistors and capacitors you need to rely on for your projects.

- Prototype & Test: A handy trick here is that when you are buying resistors and capacitors, then always test them on a prototype of your actual PCB to see if they work on it as you desire or not. This eventually saves you from loss of investment and reworking.

Tips for Selecting Resistor and Capacitor Components for PCB Design

· Component Footprint Conclusions

Today, PCB producers have to pay heed to the component footprint decisions. In this way, producers will be able to determine land patterns at the same time. Always relying on prints that are similar to the land designs is beneficial. You can use datasheets for this purpose to omit the chances of errors and faults greatly.

· Good Grounding Techniques

Make sure that the ground planes are in an accurate position in the setup because these are one of the most important PCB parts. We can combine ICs with capacitors to make the setup more efficient in its performance in the long run. For grounding purposes, it is better to check the size and frequency of the capacitors.

· Guarantee to Have Complete BOM Data

It is crucial that you consider the BOM, which is the bill of materials. So that you can evaluate your expenses on all counts; in this way, you will be able to prioritize your investment and only rely on much-needed PCB parts on all counts. Therefore considering BOM data always comes in handy when producing PCBs on a commercial scale.

· Check Spare Gates

Another good practice that you can follow is to check the spare gates. These gates work as barriers to provide a seamless pathway for combining the input with its corresponding signals. This step completely prevents floating. Spare gates are important for your setups because you can ensure efficient performance through them successfully.

· One Pad For One Connection

Follow the one-pad-for-one connection approach. It eventually helps with the seamless PCB component arrangement and makes the assembly flawless. The pads must be of suitable sizes, and if not, you will have to face complications in the process of soldering PCBs later.

· Component Package Choice

Always determine the package size for your projects. You cannot adjust large components in a small PCB and vice versa. Therefore package size determination is crucial in this regard so that you can avoid complicated PCB development easily.

Recap!

We hope that now you can choose the perfect capacitors and resistors for your future projects. After reading the important factors that help you pick the right resistor and capacitor, you will be able to reduce the chances of failures and risks for your PCBs from this day forward.