Printed circuit boards (PCBs) form the foundational backbone of electronics, but often need trimming to size before deployment in products. Cutting PCBs properly ensures precision standalone boards or panels ready for population.

This comprehensive guide covers PCB cutting methods, tools, materials, techniques and best practices in detail, including:

- Cutting goals and challenges

- Manual and automated cutting options

- Blade selection, speeds and feeds

- Fixturing, alignment and clamping

- Quality and safety considerations

- Hands-on step-by-step process

Follow along to learn essential PCB cutting skills for fabrication workflows or one-off prototyping!

Cutting Goals and Challenges

Why cut PCB boards, and why is it tricky?

Goals

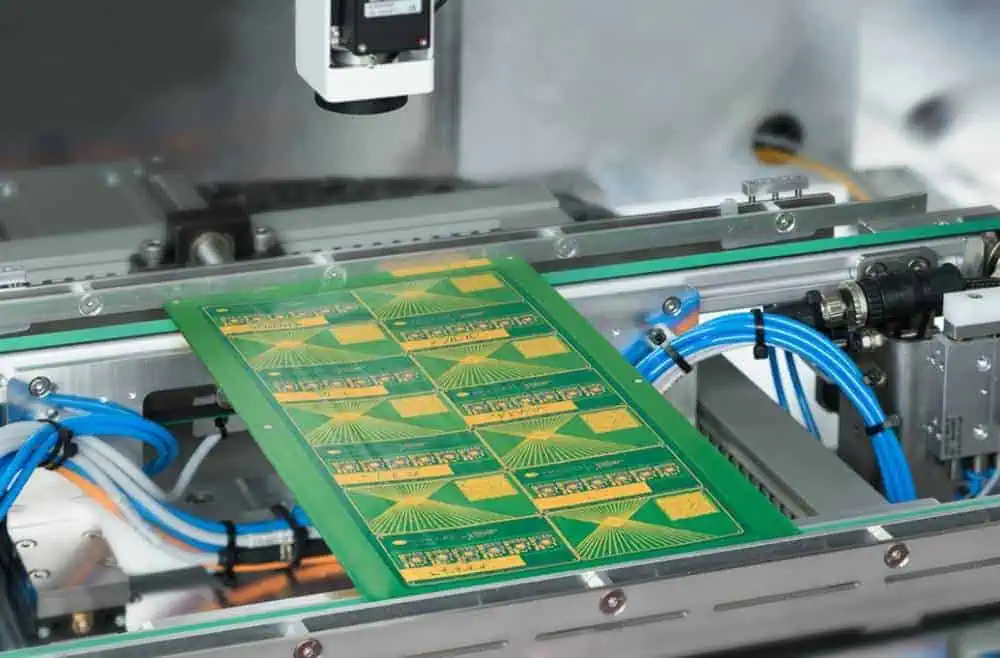

- Individualize boards from panelized arrays

- Remove damaged sections

- Custom resize or reshape

- Salvage functioning sub-sections

Challenges

- Thin laminates prone to bending

- Brittle glass fabric composites

- Delicate surface finish damage

- High precision demanded

- Composite material inconsistencies

Balancing these factors ensures quality boards ready for component assembly and integration.

Manual Vs. Automated Cutting

PCB cutting methods fall under two main approaches:

Manual

- Handheld knives, shears and nibblers

- Simple, portable and affordable

- Slow, inconsistent, labor intensive

Automated

- CNC routers and automated saws

- Fast, consistent and scalable

- Expensive equipment investment

- Overkill for small batches

Combine approaches for flexibility across needs from small-scale prototyping to high volume fabrication.

Cutting Process Steps

The PCB cutting best practices to follow are:

1. Board Preparation

- Remove protective peel-off layers

- Clean surfaces if needed

- Cover components already soldered

2. Fixturing & Alignment

- Square boards against straight fences

- Clamp boards down securely

- Align cut paths precisely

3. First Pass Cut

- Set safe blade depth just into substrate

- Use moderate feed rates

- Check cut accuracy after pass

4. Final Cut

- Complete cut through entire thickness

- Clean debris buildup frequently

- Inspect cuts for integrity

5. Post-Processing

- Smooth out burrs or fibers

- Remove dust and residues

- Pack panels to avoid bending

Meticulously following these steps enhances cutting quality.

Cutting Machines and Blades

Choosing suitable cutting hardware paves the way for success:

Key Considerations

- Blade material and tooth profile

- Machine power and precision

- Customized tool paths

- Cooling and debris removal

- Balanced feeds and speeds

Research options compatible with your board materials and project parameters.

Fixturing, Alignment and Clamping

Secure fixturing ensures cut accuracy:

Fixtures

- Flat tables or frames

- Precise 90° fences

- Custom jigs to orient boards

Alignment

- Visual guides like grids

- Laser projections

- Machined locating pins

Clamps

- Edge clamps with protective jaws

- Low profile vacuum chucks

- Adhesives fixtures for odd shapes

Immobilizing boards precisely perpendicular to cutting axes guarantees reliability.

Quality Control Checks

Verify cut quality through:

Visual Inspection

- Clean, smooth edge finish

- No cracks or delamination

- Minimal burring

Continuity Testing

- Verify electrical connections intact

- No short circuits

- Check test point access

Dimensional Checks

- Confirm precision width/length

- Ensure squareness, alignment

- Validate fit and assembly

Metrology testing ensures specifications are met.

Safety Tips

Follow safety protocols:

- Use eye and respiratory protection

- Contain fiber and debris

- Secure long hair and clothing

- Mind power cords and dust collection

- Let equipment stop fully before handling

Caution ensures injury and damage avoidance!

Manual Cutting Step-By-Step

Here are the steps to manually cut PCBs:

Materials Needed

- PCB panel with cutlines marked

- Metal ruler or grid

- Utility knife with fresh blades

- Cutting mat worksurface

- Isopropyl alcohol and wipe

Process

1. Inspect Panel

Check for damage, warp or missed fab details.

2. Secure in Vise

Clamp panel flat and oriented squarely.

**3. Align Ruler **

Position ruler flush and parallel to cut.

4. Score Cutline

Lightly cut through mask and copper.

5. Incremental Passes

Repeat scoring with incremental pressure until cut through. Clean debris.

6. Edge Cleanup

Smooth out any burrs with a fine file.

7. Final Cleaning

Wipe away all dust with alcohol soaked wipe.

With practice, clean manual PCB cuts become easy!

Frequently Asked Questions

Here are answers to common PCB cutting FAQs:

Q: Can I use a handheld jigsaw or bandsaw to cut PCBs?

A: Yes, but the rapid coarse blades will likely fray laminate edges. Use fine finish blades and low feed rates instead for cleaner results.

Q: What are some signs of cutting issues or inadequate performance?

A: Watch for discoloration from overheating, jagged edges from dull tools, wandering paths, incomplete cuts, debris buildup on tools, and fraying on top or bottom surfaces.

Q: How do I cut complex board outlines or internal features?

A: CNC routers offer the best solution with customizable tool paths. For simple shapes, repeated straight cuts or nibbling can work but take more effort.

Q: Is it possible to hand cut PCB substrates over 2mm thickness?

A: Yes, but use extreme sharp carbide blades, scoring, tangential approaches to avoid cracking, and tiny increments to limit force required. Clamp boards tightly and mind hand safety.

Q: Can inadequate cutting damage PCB functionality?

A: Yes, fractured layers can disconnect traces, debris can short traces, heat can melt solder masks, and bending can crack components or joints leading to failure.

Conclusion

With the right manual or automated tools, techniques and quality checks, PCB boards can be cut to specification quickly while avoiding damage even on delicate high density boards. Carefully follow fundamental precision fixturing, controlled cutting and inspection methods to guarantee perfectly trimmed boards ready for installation and deployment.

Confidently master essential PCB board cutting skills using this reference to smoothly handle any custom modifications needed in your electronics workflow. Your expertise at cleanly shearing boards guarantees quality soldering, assembly and integration down the line!