The rapid evolution of unmanned aerial vehicle (UAV) technology has placed unprecedented demands on electronic systems, making advanced drone PCB design a critical factor in achieving superior flight performance, reliability, and efficiency. As drones become more sophisticated and take on increasingly complex missions, the printed circuit board serves as the central nervous system that orchestrates everything from basic flight stability to advanced autonomous navigation capabilities.

Modern drone PCB architecture represents a convergence of multiple engineering disciplines, requiring expertise in high-frequency circuit design, power management, electromagnetic compatibility, and thermal engineering. The stakes are particularly high in drone applications, where a PCB failure can result in catastrophic consequences, making reliability and redundancy paramount considerations in the design process.

Understanding the Drone PCB Ecosystem

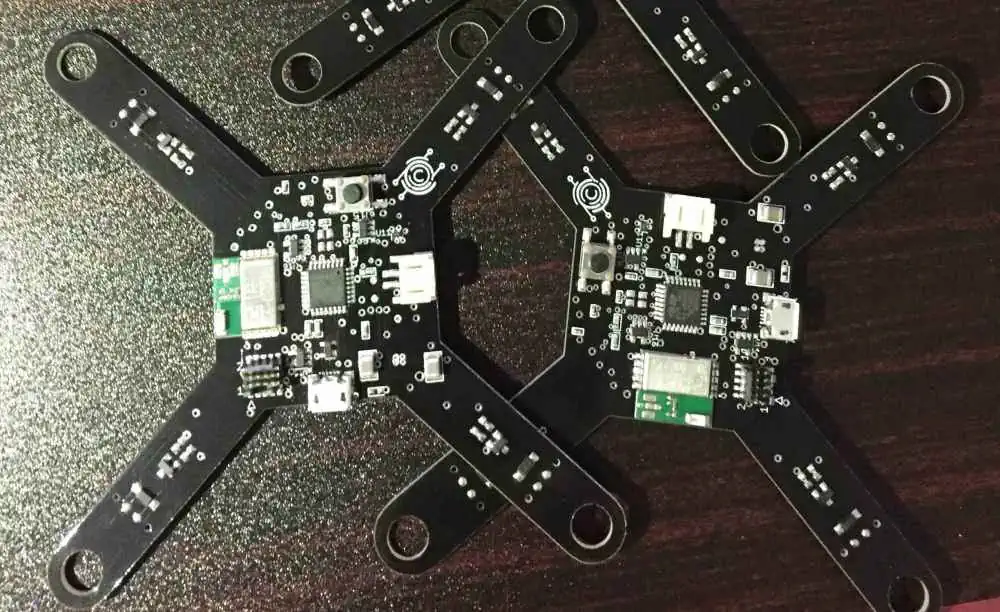

The contemporary drone PCB ecosystem encompasses far more than traditional circuit board design principles. Today’s advanced UAV systems integrate multiple subsystems including flight control units, sensor arrays, communication modules, power distribution networks, and payload interfaces, all of which must coexist harmoniously on a single board or interconnected multi-board system.

Flight control represents the most critical aspect of drone PCB design, as it directly impacts the vehicle’s ability to maintain stable flight, respond to pilot commands, and execute autonomous missions. The flight control unit typically incorporates high-performance microcontrollers or specialized flight processors that must process sensor data in real-time while maintaining precise control over motor speeds and servo positions.

Power distribution systems within drone PCBs face unique challenges due to the high current demands of brushless motors, the voltage sensitivity of onboard electronics, and the weight constraints inherent in aerial applications. Unlike terrestrial applications where weight is rarely a primary concern, every gram matters in drone design, making PCB weight optimization a crucial consideration.

Flight Control System Architecture

The heart of any advanced drone PCB lies in its flight control system architecture, which must seamlessly integrate multiple sensor inputs, process complex algorithms, and provide real-time outputs to actuators and motors. Modern flight controllers typically employ 32-bit ARM Cortex processors running at frequencies exceeding 100MHz, providing the computational power necessary for advanced flight modes and autonomous operations.

Sensor integration represents one of the most challenging aspects of drone PCB design, as modern UAVs incorporate accelerometers, gyroscopes, magnetometers, barometric pressure sensors, GPS modules, and optical flow sensors. Each sensor type presents unique interface requirements, from high-speed SPI communications to precise analog signal conditioning. The drone PCB must provide clean, stable power to these sensitive components while minimizing electromagnetic interference that could compromise sensor accuracy.

Inertial measurement units (IMUs) require particular attention in drone PCB layout, as they form the foundation of flight stability. These sensors are extremely sensitive to vibration and electromagnetic interference, necessitating careful mechanical isolation and strategic placement away from high-current switching circuits. Advanced drone PCBs often incorporate multiple IMUs for redundancy, requiring sophisticated sensor fusion algorithms to combine multiple data streams into a single, reliable state estimate.

The real-time nature of flight control demands that the drone PCB architecture minimize latency between sensor input and actuator output. This requirement influences everything from processor selection to trace routing, as even microsecond delays can impact flight performance in high-speed or precision applications.

Power Distribution Network Design

Power distribution represents one of the most complex challenges in advanced drone PCB design, as the system must efficiently manage power flows ranging from high-current motor drives to sensitive low-voltage digital circuits. Modern drone power systems typically operate from lithium polymer batteries providing 11.1V to 25.2V, which must be converted to multiple voltage rails serving different subsystems.

The drone PCB power distribution network must handle several critical requirements simultaneously. Motor electronic speed controllers (ESCs) may draw currents exceeding 30 amperes during peak operation, while flight control processors require clean, stable 3.3V or 5V supplies with minimal ripple. Camera gimbals and sensors often require additional voltage rails, creating a complex web of power requirements that must be efficiently managed.

Switching power supplies have become the standard for drone PCB applications due to their superior efficiency compared to linear regulators. However, the high-frequency switching nature of these supplies introduces electromagnetic interference challenges that must be carefully managed through proper layout techniques and filtering strategies. The drone PCB designer must balance efficiency, size, weight, and electromagnetic compatibility to achieve optimal performance.

Current sensing and monitoring capabilities are increasingly important in advanced drone PCBs, providing real-time feedback on system health and enabling sophisticated battery management features. These monitoring systems allow flight controllers to make intelligent decisions about power allocation, provide early warnings of impending system failures, and optimize flight parameters for maximum endurance.

Electromagnetic Compatibility Challenges

The confined space and high component density typical of drone PCBs create significant electromagnetic compatibility challenges that can compromise system performance if not properly addressed. Radio frequency interference from switching power supplies, high-speed digital circuits, and wireless communication modules can interfere with sensitive sensors, GPS reception, and radio control links.

Advanced drone PCB designs employ multiple strategies to minimize electromagnetic interference, including strategic component placement, proper grounding techniques, and the use of shielding structures. High-current motor drive circuits are typically isolated from sensitive analog circuits, while communication modules are positioned to minimize interference with other subsystems.

Ground plane design plays a crucial role in drone PCB electromagnetic compatibility, as improper grounding can create ground loops that introduce noise and interference. Advanced designs often employ multiple ground planes or split ground techniques to isolate different circuit blocks while maintaining proper return paths for high-frequency signals.

The increasing use of wireless communication systems in drones, including WiFi, Bluetooth, and proprietary radio links, adds another layer of complexity to electromagnetic compatibility design. These systems must coexist with other onboard electronics without causing mutual interference, requiring careful frequency planning and antenna placement.

Thermal Management Strategies

Thermal management represents a critical yet often overlooked aspect of drone PCB design, as the confined spaces and limited airflow typical of UAV applications can lead to component overheating and performance degradation. Power-hungry components such as processors, power regulators, and motor drivers generate significant heat that must be effectively dissipated to maintain reliable operation.

The drone PCB thermal design must account for both steady-state and transient thermal conditions, as component temperatures can vary dramatically during different flight phases. High-power maneuvers may cause temporary spikes in component temperatures that must be managed without compromising system reliability.

Advanced thermal management techniques for drone PCBs include the use of thermal vias to conduct heat through the board substrate, copper pour areas to spread heat across larger surface areas, and strategic component placement to avoid thermal hotspots. In some cases, active cooling solutions such as small fans or heat pipes may be incorporated, though these add weight and complexity.

The selection of appropriate PCB materials becomes crucial in high-temperature applications, as standard FR-4 substrates may not provide adequate thermal performance for demanding applications. Advanced materials such as metal-core PCBs or ceramic substrates may be required for the most challenging thermal environments.

Component Selection and Integration

The selection and integration of components for advanced drone PCBs requires careful consideration of multiple factors including performance, reliability, size, weight, and cost. Every component choice impacts overall system performance, making the selection process critical to mission success.

Microcontroller selection forms the foundation of drone PCB design, with factors including computational performance, peripheral availability, real-time capabilities, and power consumption all playing important roles. Modern flight controllers often employ dual-core processors or heterogeneous processing architectures that combine high-performance application processors with dedicated real-time control units.

Sensor selection requires balancing performance requirements with size and power constraints. High-performance inertial measurement units provide superior accuracy and stability but may consume more power and occupy more board space than lower-performance alternatives. The drone PCB designer must carefully evaluate these trade-offs based on specific mission requirements.

Power management components represent another critical selection area, as the efficiency and reliability of voltage regulators directly impact flight time and system reliability. Advanced power management integrated circuits provide sophisticated features such as power sequencing, fault protection, and telemetry capabilities that enhance overall system performance.

Manufacturing and Quality Considerations

The manufacturing of advanced drone PCBs requires specialized processes and quality control measures to ensure reliable operation in demanding environments. The high component density and mixed-signal nature of drone circuits place stringent requirements on manufacturing tolerances and assembly processes.

Surface mount technology (SMT) assembly has become the standard for drone PCB manufacturing due to its superior density and reliability compared to through-hole techniques. However, the small component sizes and tight spacing typical of drone applications require advanced assembly equipment and careful process control to achieve acceptable yields.

Quality control measures for drone PCBs must address both electrical performance and mechanical reliability, as the vibration and shock environments encountered in flight can cause component failures or solder joint fatigue. Specialized testing procedures including vibration testing, thermal cycling, and accelerated aging may be required to validate design reliability.

The use of automated test equipment (ATE) becomes increasingly important as drone PCBs become more complex, providing comprehensive functional testing that would be impractical to perform manually. These test systems can verify not only basic electrical functionality but also dynamic performance characteristics such as sensor response times and control loop stability.

Future Trends and Innovations

The future of drone PCB design is being shaped by several emerging trends and technologies that promise to further enhance UAV capabilities while addressing current limitations. Advanced materials, new component technologies, and innovative design approaches are driving the next generation of drone electronics.

Three-dimensional PCB structures represent an emerging trend that promises to further increase component density while reducing overall system size and weight. These advanced structures allow components to be mounted on multiple layers of the PCB, creating truly three-dimensional electronic systems that maximize space utilization.

The integration of artificial intelligence and machine learning capabilities directly into drone PCBs is becoming increasingly practical as specialized AI processors become smaller and more power-efficient. These capabilities enable advanced autonomous behaviors and adaptive control algorithms that can improve flight performance and mission success rates.

Advanced power management technologies, including wireless power transfer and energy harvesting capabilities, are being explored as methods to extend flight endurance and reduce dependence on traditional battery systems. These technologies may fundamentally change how drone power systems are designed and integrated.

Conclusion

Advanced drone PCB design represents a complex engineering challenge that requires expertise across multiple disciplines and careful consideration of numerous competing requirements. The successful integration of flight control systems, power distribution networks, sensor arrays, and communication modules requires a holistic approach that considers not only individual component performance but also system-level interactions and emergent behaviors.

As drone technology continues to evolve and UAVs take on increasingly sophisticated missions, the demands placed on drone PCB designs will only increase. Future designs must balance performance, reliability, size, weight, and cost while incorporating new technologies and capabilities that enable next-generation autonomous flight systems.

The key to successful drone PCB design lies in understanding the unique requirements and constraints of aerial applications while applying advanced engineering principles and best practices. By carefully considering factors such as electromagnetic compatibility, thermal management, power distribution, and manufacturing requirements, designers can create drone PCBs that enable reliable, high-performance UAV operations across a wide range of applications and environments.

Success in this field requires continuous learning and adaptation as new technologies emerge and mission requirements evolve. The most effective drone PCB designs will be those that not only meet current requirements but also provide the flexibility and scalability necessary to accommodate future enhancements and capabilities.

Related posts:

- Premium Drone PCB Board & Circuit Board with Remote Control – Best Price for Drone Receiver & Controller PCBs

- Military PCB Design & Manufacturing: A Complete Guide to MIL-SPEC Compliance

- The Complete Guide to Aluminum PCB Manufacturing Process: From Design to Delivery

- Inverted-F Antenna (IFA/PIFA) Design: A Complete Guide to 2.4 GHz, Dual-Band, and Mobile Applications