When you’ve invested hours designing a printed circuit board (PCB), ordered the components, carefully soldered everything in place, and powered it up for the first time—only to find it doesn’t work—frustration is natural. However, debugging a non-working PCB is a methodical process that can be both educational and rewarding. With the right approach, tools, and patience, most PCB issues can be identified and resolved.

Initial Assessment and Safety

Before diving into debugging, ensure your workspace is safe and properly organized. Check that your power supply is set to the correct voltage and current limits. If your PCB is designed for 3.3V, accidentally applying 5V could damage sensitive components irreversibly. Always start with the lowest reasonable voltage and gradually increase while monitoring current consumption.

Begin with a visual inspection using good lighting and magnification. Look for obvious issues like solder bridges, cold solder joints, missing components, or components installed backwards. Pay special attention to polarized components such as diodes, electrolytic capacitors, and integrated circuits. A backwards diode or IC can prevent the entire circuit from functioning and may cause permanent damage.

Check your PCB against the schematic and bill of materials. It’s surprisingly easy to install the wrong value resistor or capacitor, especially when component markings are small or unclear. Verify that all components are present and correctly oriented. Use a multimeter to confirm resistor values if their color codes are difficult to read.

Power Supply Verification

Power issues are among the most common causes of non-working PCBs. Start by verifying that power is reaching your board correctly. Use a multimeter to check voltage levels at key points throughout your circuit. Begin at the power input and work your way through any voltage regulators to ensure each stage is functioning properly.

Measure both DC voltage levels and AC ripple. Excessive ripple can cause digital circuits to malfunction or analog circuits to produce noisy outputs. If you have access to an oscilloscope, examine the power supply waveforms under different load conditions. A switching regulator that works fine at light loads might become unstable or drop out under heavier loads.

Current consumption is equally important. If your circuit is drawing significantly more current than expected, you likely have a short circuit or a component failure. Conversely, if it’s drawing much less current than anticipated, critical components might not be powered or functioning. Use your power supply’s current limiting feature to protect your circuit while troubleshooting.

Ground connections are often overlooked but critical. Verify continuity between all ground points on your PCB. A broken ground connection can cause erratic behavior that’s difficult to diagnose. In multi-layer boards, via failures can create ground loops or isolated ground islands.

Systematic Signal Tracing

Once you’ve confirmed that power is distributed correctly, move on to signal tracing. Start from inputs and work toward outputs, or begin with known good signals and follow them through the circuit. This methodical approach helps isolate the problem to specific sections of your design.

For digital circuits, use a logic analyzer or oscilloscope to examine signal integrity. Check for proper voltage levels, timing relationships, and signal quality. Look for issues like ringing, overshoot, undershoot, or excessive rise/fall times. These problems often stem from improper termination, ground plane issues, or electromagnetic interference.

In analog circuits, signal tracing becomes more nuanced. Use an oscilloscope to examine waveforms at various stages of amplification or filtering. Compare measured results with your design calculations. Pay attention to frequency response, gain, offset voltages, and noise levels. A slight DC offset early in a signal chain can become a major problem after several stages of amplification.

Don’t forget about clock signals in digital systems. Clock integrity is crucial for proper operation. Verify that clock signals have appropriate amplitude, frequency, and duty cycle. Check for clock skew between different parts of your circuit, especially in high-speed designs.

Component-Level Testing

When system-level debugging doesn’t reveal the problem, it’s time to test individual components. Remove suspect components from the circuit when possible and test them independently. This is especially important for active components like transistors, operational amplifiers, and microcontrollers.

For semiconductors, check basic parameters like forward voltage drops on diodes, transistor beta values, and op-amp offset voltages. Compare these measurements with datasheet specifications. Components that test within specifications individually might still fail when operating in-circuit due to thermal effects or specific bias conditions.

Passive components can also fail in subtle ways. Capacitors might have correct capacitance but excessive equivalent series resistance (ESR) or leakage current. Inductors can have shorted turns that reduce their effective inductance. Even resistors can drift from their nominal values, especially if they’ve been stressed by overcurrent conditions.

Crystal oscillators deserve special attention in digital designs. These components are sensitive to loading conditions, temperature, and mechanical stress. If a crystal isn’t oscillating, check the load capacitors, bias resistors, and PCB layout around the oscillator circuit. Sometimes, simply touching the crystal with a probe is enough to start or stop oscillation, indicating a marginal design.

Advanced Debugging Techniques

For complex problems that resist conventional debugging approaches, advanced techniques may be necessary. Thermal imaging can reveal components that are running unexpectedly hot, indicating possible failures or design issues. Conversely, components that should be warm but remain cool might not be functioning at all.

In RF and high-frequency circuits, network analyzers can measure impedance, return loss, and insertion loss. These measurements help identify problems with transmission lines, matching networks, and filter circuits that might not be apparent with conventional instruments.

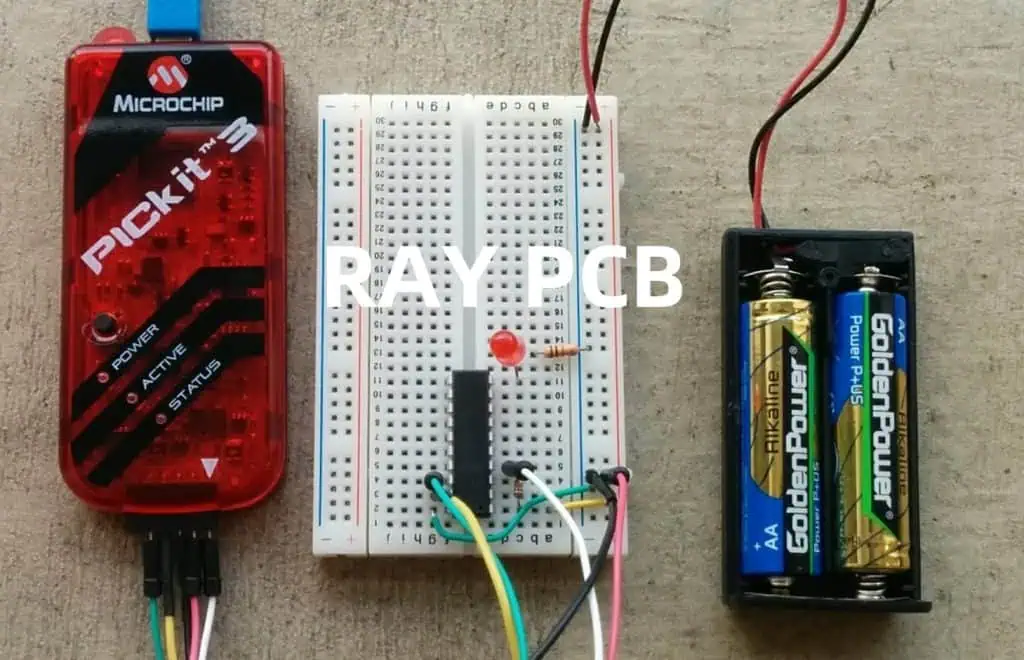

For microcontroller-based designs, in-circuit debugging tools like JTAG interfaces provide invaluable insight into program execution. You can set breakpoints, examine memory contents, and step through code execution to identify software-related issues. Sometimes what appears to be a hardware problem is actually a software bug.

Boundary scan testing, where available, allows you to test interconnections and basic functionality of digital ICs without removing them from the circuit. This technique is particularly useful for complex designs with fine-pitch components that are difficult to probe directly.

Environmental and Layout Considerations

PCB layout issues can cause problems that are difficult to diagnose with conventional approaches. Poor ground plane design can create ground loops, causing noise and instability. Inadequate power plane design might cause voltage drops or noise coupling between different circuit sections.

Electromagnetic interference (EMI) can cause intermittent problems that are particularly frustrating to debug. Use an oscilloscope with good bandwidth to look for high-frequency noise on power and signal lines. Sometimes adding small bypass capacitors or ferrite beads can resolve these issues.

Thermal effects can cause components to behave differently than expected. Some failures only occur when the PCB reaches operating temperature, while others might disappear as components warm up. Use a heat gun or cooling spray to deliberately change component temperatures while monitoring circuit behavior.

Mechanical stress can also affect PCB performance. Flexing the board slightly while powered might reveal intermittent connection problems. Pay attention to areas where the PCB might be under mechanical stress, such as connector mounting points or areas near mounting holes.

Documentation and Prevention

Throughout the debugging process, maintain detailed documentation of your findings. Record which tests were performed, what measurements were taken, and what changes were made. This documentation becomes invaluable if similar problems occur in future designs or if you need to reproduce your debugging steps.

Consider implementing design for testability (DFT) features in future PCBs. Test points, LED indicators, and jumpers can significantly simplify debugging. Design in current measurement points and voltage monitoring capabilities where appropriate.

Review your design and manufacturing processes to prevent similar issues in the future. Was the problem caused by a design error, a manufacturing defect, or a component failure? Understanding root causes helps improve your design methodology and reduces the likelihood of similar problems in subsequent projects.

Conclusion

Debugging a non-working PCB requires patience, systematic thinking, and the right tools. Start with basic power and visual checks before moving to more sophisticated signal analysis. Remember that the most complex-seeming problems often have simple causes—a backwards diode or solder bridge can render an entire design non-functional.

The debugging process, while sometimes frustrating, is an excellent learning opportunity. Each problem solved adds to your experience and makes future debugging efforts more efficient. With practice, you’ll develop an intuition for where problems are likely to occur and how to isolate them quickly.

Most importantly, don’t give up too quickly. Many PCB problems that initially seem insurmountable can be resolved with methodical debugging. The satisfaction of bringing a non-working design to life makes the effort worthwhile and contributes significantly to your growth as an electronics engineer.

Related posts:

- FPGA Programming Guide: From VHDL to Python – Tools, JTAG Debugging & SPI Flash Configuration

- The Essential Guide to LDR Circuit (Light Dependent Resistor) & Its Working

- The Essential Guide to Hall Effect Sensor Circuit – Working

- The Essential Guide to Voltage Sensor Circuit: Types & Working Principle