In the realm of high-speed digital electronics and radio frequency (RF) systems, signal integrity plays a crucial role in ensuring the reliable transmission and reception of data. One often overlooked factor that can significantly impact signal integrity is the roughness of the copper surface on printed circuit boards (PCBs). This comprehensive article delves into the intricacies of copper roughness, its causes, measurement techniques, and its profound effect on signal integrity in modern electronic systems.

Understanding Copper Roughness

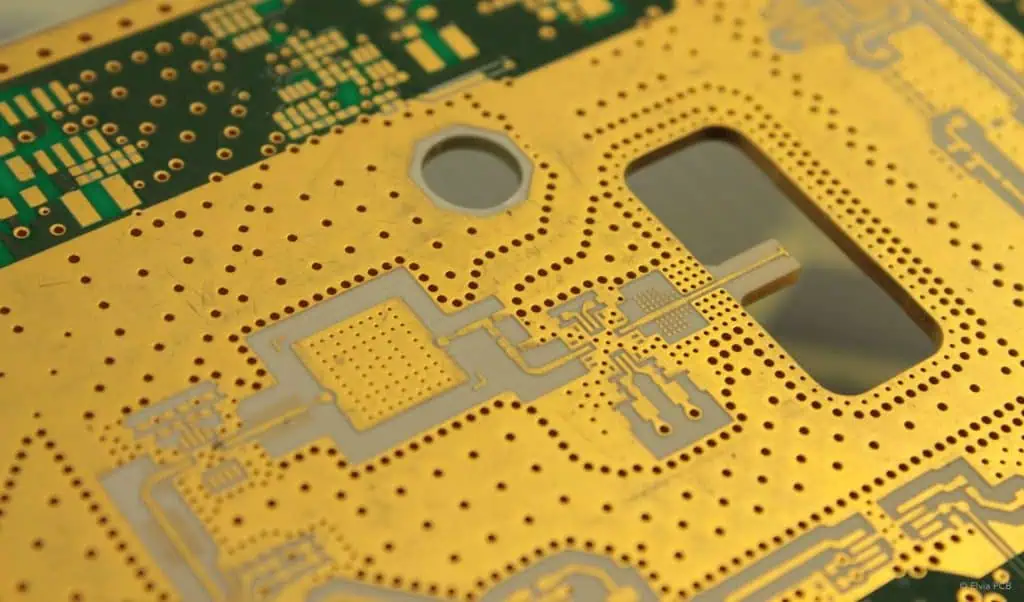

Copper roughness, also known as surface roughness, refers to the microscopic irregularities or deviations from a perfectly smooth surface on the copper traces and planes of a PCB. These irregularities can arise from various factors during the PCB manufacturing process, such as etching, plating, and lamination techniques.

Copper roughness is typically expressed in terms of roughness parameters, such as the root mean square (RMS) roughness or the peak-to-valley height. These parameters quantify the magnitude of the surface irregularities and provide a way to compare and specify the roughness levels of different PCBs.

Causes of Copper Roughness

Several factors can contribute to the roughness of the copper surface on PCBs, including:

- Etching Process: The etching process used to remove unwanted copper from the PCB’s substrate can leave behind microscopic irregularities on the remaining copper surfaces. The type of etchant, etching duration, and the etching technique employed can influence the resulting copper roughness.

- Electroplating: Electroplating is a common process used to deposit copper onto the PCB’s substrate. The plating parameters, such as current density, bath chemistry, and additives, can impact the smoothness of the deposited copper layer.

- Lamination Process: During the lamination process, the copper foil is bonded to the PCB’s dielectric substrate. The adhesion promotion techniques used, as well as the quality of the copper foil itself, can contribute to the overall copper roughness.

- Surface Treatments: Various surface treatments, such as oxidation or reduction processes, may be applied to the copper surfaces to improve adhesion or modify their properties. These treatments can potentially affect the smoothness of the copper surface.

Measuring Copper Roughness

To characterize and quantify copper roughness, several measurement techniques are employed in the PCB industry. These techniques include:

- Profilometry: Profilometry techniques, such as stylus profilometry or optical profilometry, directly measure the surface profile of the copper traces or planes. These techniques provide detailed information about the roughness parameters and can generate 2D or 3D surface profiles.

- Microscopy: Scanning electron microscopy (SEM) or atomic force microscopy (AFM) can be used to capture high-resolution images of the copper surface, allowing for visual inspection and analysis of the roughness features.

- Electrical Measurement: Certain electrical measurement techniques, such as the transmission line pulse (TLP) method or the line-roughness measurement (LRM) technique, can indirectly assess copper roughness by analyzing the electrical characteristics of the PCB traces or planes.

The choice of measurement technique depends on factors such as the required accuracy, measurement scale, and available equipment. Accurate measurement and characterization of copper roughness are essential for understanding its impact on signal integrity and developing strategies to mitigate its effects.

Effect of Copper Roughness on Signal Integrity

Copper roughness can have significant consequences for signal integrity in high-speed and high-frequency electronic systems. The key effects of copper roughness include:

1. Increased Signal Attenuation

Roughness on the copper surface can cause additional signal losses due to increased skin effect and surface scattering. As the signal frequency increases, these losses become more pronounced, leading to higher signal attenuation and reduced transmission distances.

2. Impedance Discontinuities

Variations in the copper roughness along a transmission line can create localized changes in the effective cross-sectional area of the conductor, leading to impedance discontinuities. These discontinuities can cause signal reflections, ringing, and increased crosstalk, degrading signal quality.

3. Mode Conversion and Radiation

In differential signaling systems, copper roughness can cause mode conversion, where energy from the differential mode is converted into the common mode or vice versa. This mode conversion can lead to increased electromagnetic interference (EMI) and radiation, affecting signal integrity and potentially violating regulatory compliance.

4. Increased Insertion Loss

The increased surface area resulting from copper roughness can lead to higher capacitive and inductive losses, contributing to increased insertion loss in high-frequency signals. This effect becomes more significant as the operating frequency increases.

5. Jitter and Timing Errors

In high-speed digital systems, copper roughness can contribute to increased jitter and timing errors, potentially causing data corruption or system failures. These effects are particularly critical in applications such as high-speed serial links and clock distribution networks.

To mitigate the impact of copper roughness on signal integrity, various strategies can be employed, including optimizing the PCB fabrication processes, selecting appropriate surface finishes, incorporating roughness-aware design rules, and implementing equalization techniques in the signaling systems.

Strategies for Mitigating the Effects of Copper Roughness

While copper roughness is an inherent characteristic of PCB manufacturing processes, several strategies can be employed to mitigate its impact on signal integrity:

1. Optimized Fabrication Processes

Manufacturers can optimize their PCB fabrication processes to minimize copper roughness. This may involve adjusting etching parameters, employing advanced electroplating techniques, or using specialized surface treatments to achieve smoother copper surfaces.

2. Surface Finishes

Applying appropriate surface finishes, such as electroless nickel-immersion gold (ENIG) or immersion silver (ImAg), can help reduce the effective roughness of the copper surface by providing a smoother outer layer.

3. Roughness-Aware Design Rules

PCB designers can incorporate roughness-aware design rules into their layouts, taking into account the expected copper roughness levels. These rules may include adjustments to trace widths, spacing, and impedance calculations to compensate for the effects of roughness.

4. Equalization and Signal Processing

In high-speed digital systems, equalization techniques, such as transmitter pre-emphasis, receiver equalization, or continuous-time linear equalization (CTLE), can be employed to mitigate the effects of copper roughness on signal quality.

5. Material Selection

Careful selection of PCB materials, such as low-loss dielectric substrates and smoother copper foils, can help minimize the inherent roughness and its impact on signal integrity.

6. Design Validation and Modeling

Incorporating copper roughness models into signal integrity simulations and performing thorough design validation can help identify potential issues early in the design cycle and guide the implementation of appropriate mitigation strategies.

By adopting a combination of these strategies, electronics manufacturers and PCB designers can effectively manage the effects of copper roughness and ensure reliable signal integrity in their high-speed and high-frequency electronic systems.

Copper Roughness and Industry Standards

To ensure consistent and reliable performance of electronic systems, various industry standards and specifications have been established to address copper roughness. These standards provide guidelines, measurement techniques, and roughness limits for different applications and frequency ranges.

Some of the commonly referenced standards related to copper roughness include:

- IPC-A-600 “Acceptability of Printed Boards”

- IPC-6012 “Qualification and Performance Specification for Rigid Printed Boards”

- IPC-6018 “Qualification and Performance Specification for High-Speed/High-Frequency Rigid Printed Board Laminates”

- IEEE 802.3 Ethernet standards (e.g., 802.3ck for 100 Gb/s Ethernet)

These standards provide valuable guidance for PCB manufacturers, designers, and system integrators, helping them ensure compliance and maintain signal integrity in their products.

Frequently Asked Questions (FAQ)

- What is copper roughness, and why is it important? Copper roughness refers to the microscopic irregularities or deviations from a perfectly smooth surface on the copper traces and planes of a PCB. It is important because it can significantly impact signal integrity, especially in high-speed and high-frequency electronic systems, by causing signal attenuation, impedance discontinuities, mode conversion, and increased insertion loss.

- What are the main causes of copper roughness? The main causes of copper roughness include the etching process, electroplating techniques, lamination process, and surface treatments applied during PCB manufacturing.

- How is copper roughness measured? Copper roughness is typically measured using techniques such as profilometry (stylus or optical), microscopy (SEM or AFM), or electrical measurement methods like the transmission line pulse (TLP) or line-roughness