Selecting the right PCB prototype assembler is a critical decision that can significantly impact your product development timeline, quality, and overall project success. With numerous options available in the market, from local shops to international manufacturers, making an informed choice requires careful consideration of multiple factors. This comprehensive guide will walk you through the essential criteria and considerations for choosing a professional PCB prototype assembler that best fits your specific needs.

Understanding Your Project Requirements

Before evaluating potential assemblers, clearly define your project specifications and requirements. Consider the complexity of your PCB design, including the number of layers, component density, and types of components you’ll be using. Surface-mount technology (SMT) components, through-hole components, and mixed assemblies each present different challenges and require specific equipment and expertise. Document your expected quantities, turnaround time requirements, and quality standards. Understanding whether you need a one-time prototype or ongoing small-batch production will help narrow down suitable candidates.

Technical Capabilities and Equipment

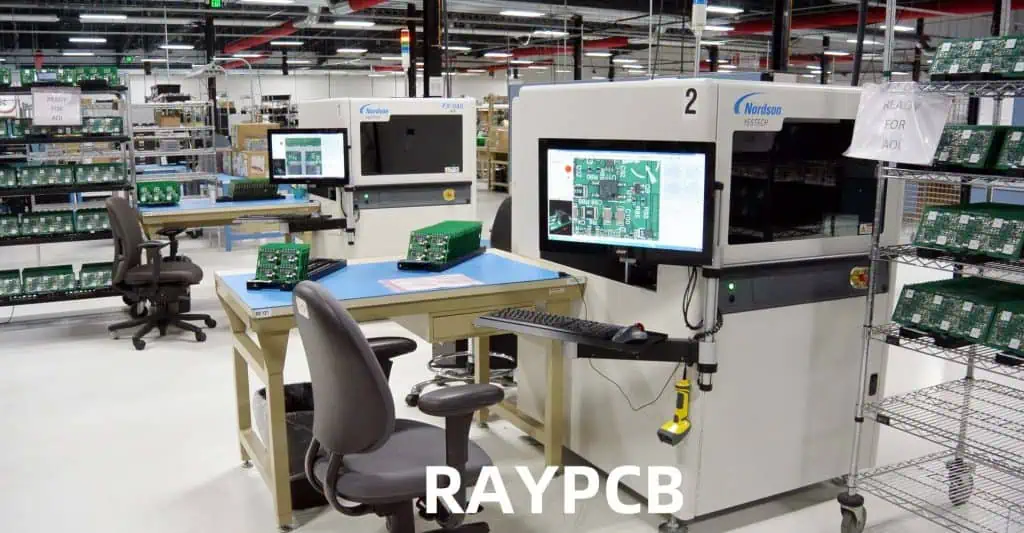

A professional PCB prototype assembler should possess modern, well-maintained equipment capable of handling your specific requirements. Look for facilities equipped with advanced pick-and-place machines, reflow ovens, wave soldering equipment, and inspection systems. The assembler should have experience with your component types, particularly if you’re using specialized parts like BGAs (Ball Grid Arrays), QFNs (Quad Flat No-leads), or high-frequency components. Inquire about their minimum component sizes they can handle, as modern designs often incorporate 0201 or even smaller components.

Ask about their PCB handling capabilities, including minimum and maximum board sizes, thickness ranges, and any special substrate materials they can work with. If your design includes rigid-flex PCBs or requires specific environmental considerations, ensure the assembler has relevant experience and equipment. The facility should also have proper anti-static controls, clean room environments where necessary, and appropriate storage conditions for moisture-sensitive components.

Quality Control and Certifications

Quality assurance is paramount when selecting a PCB prototype assembler. Look for facilities with relevant certifications such as ISO 9001, IPC-A-610 (Acceptability of Electronic Assemblies), and IPC-J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies). These certifications indicate adherence to industry standards and commitment to quality processes.

Inquire about their inspection procedures, which should include automated optical inspection (AOI), in-circuit testing (ICT), and functional testing capabilities. The assembler should provide detailed inspection reports and be willing to discuss their defect rates and quality metrics. A professional assembler will have documented procedures for handling non-conforming products and implementing corrective actions.

Experience and Expertise

Experience in your specific industry or application area can be invaluable. An assembler familiar with automotive electronics will understand different requirements than one specializing in consumer electronics or medical devices. Review their portfolio and ask for case studies or references from similar projects. Experienced assemblers can often provide valuable design feedback and suggest improvements that can enhance manufacturability and reduce costs.

Consider their engineering support capabilities. A good prototype assembler should offer design for manufacturing (DFM) reviews, helping identify potential assembly issues before production begins. They should be able to provide feedback on component selection, footprint optimization, and assembly processes that could improve your design’s reliability and manufacturability.

Communication and Customer Service

Effective communication is crucial throughout the prototype assembly process. Evaluate how responsive and clear the assembler’s communication is during initial inquiries. They should be willing to discuss your project in detail, provide accurate quotes, and explain their processes clearly. Look for assemblers who assign dedicated project managers or engineers to your account, ensuring consistent communication and accountability.

The assembler should provide regular updates on project progress and be accessible for questions or concerns. They should also be proactive in communicating any issues or potential delays, allowing you to make informed decisions about project adjustments.

Turnaround Time and Flexibility

Prototype development often operates under tight schedules, making turnaround time a critical factor. Evaluate each assembler’s standard lead times and their ability to accommodate rush orders when necessary. However, be cautious of assemblers who promise unrealistically fast turnaround times, as this may come at the expense of quality.

Consider their flexibility in handling design changes or component substitutions that might arise during the prototype phase. A good assembler should be able to accommodate reasonable modifications without significant delays or excessive charges. They should also have established relationships with component suppliers to help source hard-to-find parts or provide suitable alternatives.

Cost Considerations and Pricing Structure

While cost shouldn’t be the only deciding factor, it’s certainly important for most projects. Request detailed quotes from multiple assemblers, ensuring they include all relevant costs such as setup fees, component procurement, assembly labor, testing, and shipping. Be wary of quotes that seem significantly lower than others, as they may not include all necessary services or may compromise on quality.

Consider the total cost of ownership, including potential rework costs, shipping expenses, and the value of time saved through efficient processes. Some assemblers offer package deals for prototypes that include multiple iterations or small production runs, which can provide better overall value for ongoing projects.

Component Procurement and Supply Chain Management

Many prototype assemblers offer component procurement services, which can simplify your project management and potentially reduce costs through their supplier relationships. Evaluate their component sourcing capabilities, including their supplier network, inventory management systems, and ability to source obsolete or hard-to-find components.

Inquire about their policies regarding excess components and how they handle component returns or credits. Some assemblers maintain consignment inventory for frequently used components, which can reduce lead times for future orders. They should also have processes for verifying component authenticity and quality, particularly important in today’s market with counterfeit components.

Location and Logistics

Consider the geographic location of the assembler relative to your operations. Local or regional assemblers may offer advantages in communication, site visits, and shipping costs, while offshore options might provide cost savings for larger quantities. Evaluate their shipping options, packaging methods, and ability to meet any specific delivery requirements you might have.

For international assemblers, consider factors such as time zone differences, language barriers, customs procedures, and potential supply chain disruptions. Some projects may benefit from the cost advantages of offshore assembly, while others requiring close collaboration or quick iterations may be better served by local providers.

Making the Final Decision

After evaluating potential assemblers against these criteria, create a decision matrix weighing the factors most important to your specific project. Consider requesting samples or starting with a small trial project to evaluate their actual performance before committing to larger orders. The lowest-cost option isn’t always the best choice when considering the total impact on your project timeline and success.

Remember that building a long-term relationship with a reliable PCB prototype assembler can provide significant benefits for future projects, including improved understanding of your requirements, streamlined processes, and potentially better pricing for ongoing work.

Choosing the right PCB prototype assembler requires careful evaluation of multiple factors beyond just price and delivery time. By thoroughly assessing technical capabilities, quality systems, experience, and service levels, you can select a partner who will contribute to your project’s success and support your ongoing development needs. Take the time to properly evaluate your options, as this decision will significantly impact your prototype development experience and outcomes.