Printed Circuit boards have become the main components of the electrical gadget we utilize to undertake our day-to-day activities. Therefore, if you have used an electrical device, for example, a phone, a watch, or even a laptop, you have utilized a PCB. However, most of the time, we only experience the efficiency and the optimized performance that comes with PCBs, not the struggle that goes into manufacturing these components.

Producing a Printed circuit board requires technicians to utilize complex processes that use a lot of resources and energy. However, out of the many processes that lead to the manufacturing of a PCB, the stage tends to be more crucial than the rest—the Designing stage. However, due to its complexity, manufacturers have developed impeccable software programs to help PCB designers. One of these incredible software programs is SolidWorks PCB. SolidWorks was initially created as a modern-era, revolutionary tech for printed circuit board design integration with three-dimensional mechanical design ENV. However, after creation, this software program offers more than just this single feature. So what exactly does the SolidWorks Printed Circuit Board Software have to offer? And why should you consider using it over other competitive software programs?

Printed Circuit Boards in a Nutshell

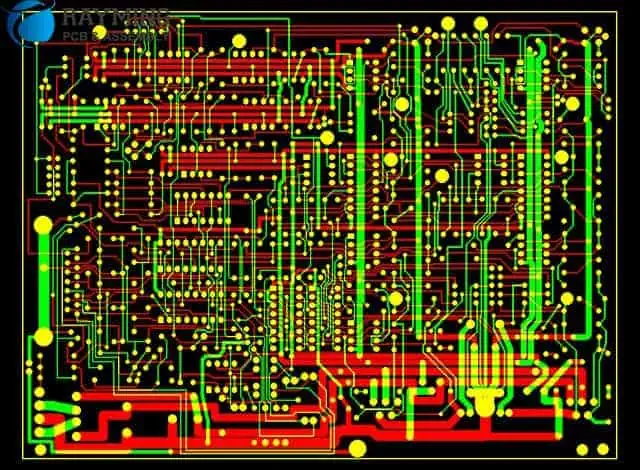

Printed circuit boards, or simply PCBs, are electronic circuits we use in electronic devices to offer electrical connectivity and mechanical support to electrical components, for example, ICs. We produce PCBs by combining various sheets of components that are non-conductive, for example, plastic or fiberglass, that can easily hold the copper circuitry.

We also refer to PCBs as Etched Wiring Boards (EWB) or Printed Wiring Boards (PWB).

A printed circuit board functions on the CU or copper circuit/assembly/films that are carefully embedded inside the non-conducive materials to offer a pathway that effectively transmits electrical current. Printed Circuit Boards can hold multiple electrical components soldered onto them without using cables. The elimination of cabling makes electrical devices that run on PCBs lighter. Moreover, it eliminates the issues that come with using cables on electrical appliances, such as higher risks of short circuits.

Printed circuit boards are present in almost every computing device and electronic gadget out there, including:

- Graphics cards

- Network cards

- Motherboards

- The internal circuitry of CD-ROM/Hard Drives

Due to their application areas, you must carefully manufacture printed circuit boards. That is because messing up might make the circuit board fail, ultimately leading to the gadget failing. And considering that circuit boards operate in critical machines such as life support machines in the medical industry, this is not something that you would want to happen.

SolidWorks Printed Circuit Board Services

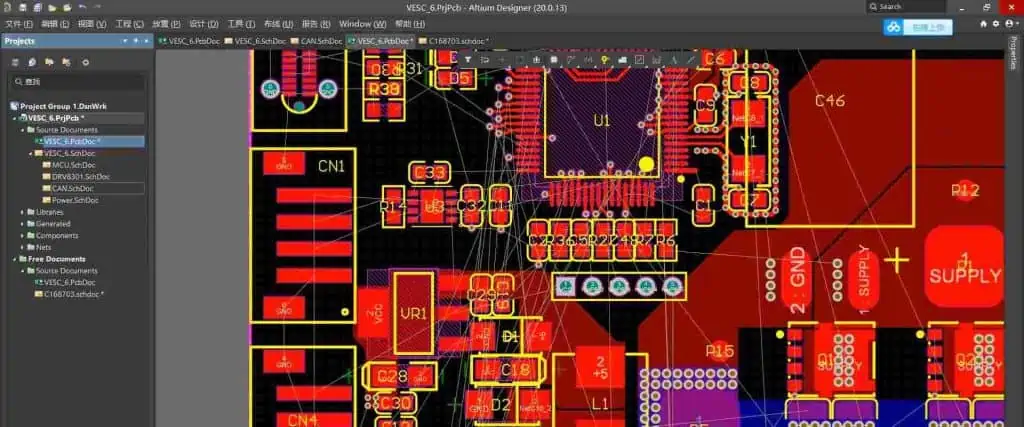

SolidWorks printed circuit board, formerly PCBWorks, is a printed circuit board (PCB) designing tool that PCB designers integrate into the popular SolidWorks three-dimensional design software. To install this program, utilize the SolidWorks Installation manager, which installs this program as an individual installation.

Electrical engineers utilizing SolidWorks PCB can easily alter the design of a PCB and then push the alterations to a repository. Moreover, mechanical engineers using this software can also easily access the altered PCB design from the prior saved repository. After accessing this design, they can analyze any modifications made, make additional alterations, and then push the new design back to its repository, where electrical engineers can access it to make more changes.

Through this collaboration, technicians can generate high-quality and optimized PCBs. Moreover, this collaboration ensures that designers catch errors in the early stages before they move the design to production.

However, to make this collaboration possible, you must install SolidWorks Printed Circuit Board Services, which effectively manages various repositories on shared servers. The SolidWorks PCB services program installs via the SolidWorks Installation manager. Hence, it doesn’t require you to purchase a new license to use this program. Moreover, this program includes databases for storing data and sync the alterations made by various mechanical and electrical engineers. It also includes MIIS or Microsoft Internet Info Services.

In various network ENVs, you install SolidWorks printed circuit board services on a shared server that doesn’t have the SolidWorks Programs installed. Moreover, you can also install this software with various SolidWorks Printed Circuit Board components on one machine.

To ensure its efficiency and effectiveness, you must have this software running 24/7. Moreover, you must ensure it has bidirectional, uninterrupted communication through virus scanners and firewalls with users running the SolidWorks program and the SolidWorks printed circuit board software.

Key Features of SolidWorks PCB

MCAD/ECAD Project Collaboration Server

MCAD/ECAD collaboration servers help you facilitate the collaboration between the mechanical and electrical sides of the PCB designing project.

Moreover, these servers also help you link electrical data to the mechanical models of SolidWorks CAD. Combining this information in one place enables you to manage your project better. Moreover, it also ensures seamless synchronization of information, which is crucial when working with a team.

Parasolid Support

The SolidWorks PCB services program supports the native Parasolid SolidWorks file format, which ultimately widens the scope of this software application-wise. Moreover, using this software, you can easily link parasolid models for component bodies and enclosures and then view them in three dimensions to ensure the board you are designing fits mechanical enclosures perfectly.

Copper Analysis

You can quickly improve your design’s accuracy using SolidWorks CAD and SolidWorks PCB. Moreover, this software lets you send your PCB design to the SolidWorks CAD bearing Copper information. After processing, you get back a detailed mechanical, vibration, and thermal simulation, which helps you view your design from a new angle or perspective. Moreover, this simulation can help you identify and fix errors before you move your design to production. Doing so will make your design less prone to errors after production.

Conclusion

Printed Circuit boards are a crucial aspect of the electrical industry. They help manufacturers produce compact electrical gadgets that are powerful and efficient. However, to use these circuit boards, they have to manufacture them first. During the manufacturing process of PCBs, technicians have to start from the designing phase, which is crucial. That’s because any mess made during this stage is carried forward to the production stage. However, to avoid this, you should utilize the SolidWorks PCB services program. It lets you collaborate with mechanical and electrical engineers to help you generate an efficient and flawless PCB design.