Heavy Copper PCB: Complete Guide to Applications, Benefits & Design

Rayming specializes in heavy copper PCB manufacturing, supporting copper weights up to 20 oz. Our experienced team excels in solder mask printing and maintains stringent quality controls to ensure superior performance in extreme copper PCB applications.

What is a Heavy Copper PCB?

A heavy copper PCB is a specialized printed circuit board featuring copper layers significantly thicker than standard PCBs. While conventional PCBs typically use copper weights ranging from 0.5 oz to 3 oz per square foot (17.5μm to 105μm), heavy copper PCBs are characterized by copper thicknesses of 3 oz/ft² or greater, with some applications requiring up to 20 oz/ft² (700μm) or even extreme copper weights reaching 200 oz/ft².

Copper Weight Classifications

| PCB Type | Copper Weight | Thickness | Typical Applications |

|---|---|---|---|

| Standard PCB | 0.5-3 oz/ft² | 17.5-105μm | Consumer electronics, basic circuits |

| Heavy Copper PCB | 3-20 oz/ft² | 105-700μm | Power electronics, automotive, industrial |

| Extreme Copper PCB | 20-200 oz/ft² | 700-7000μm | High-power military, aerospace systems |

The copper weight measurement represents the weight of copper that would cover one square foot of the PCB surface, making it a standard industry metric for specifying copper thickness across different PCB types.

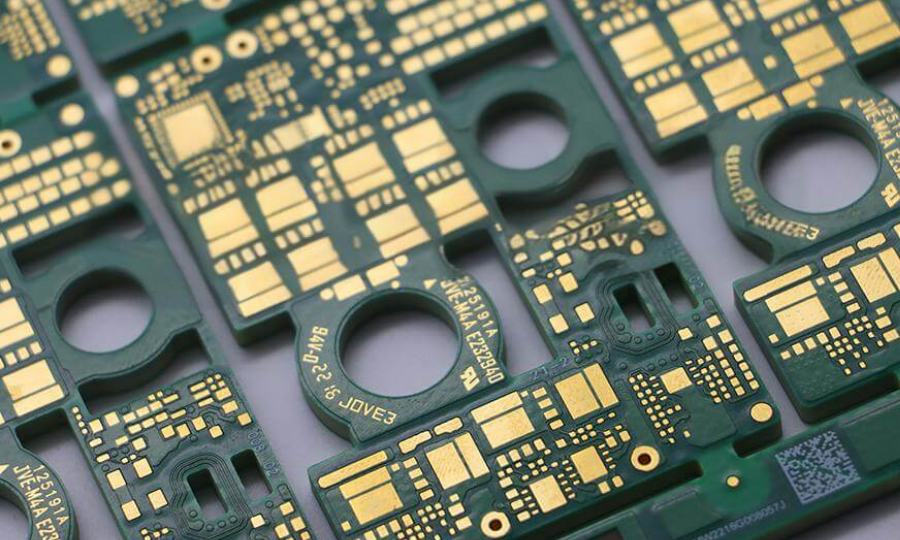

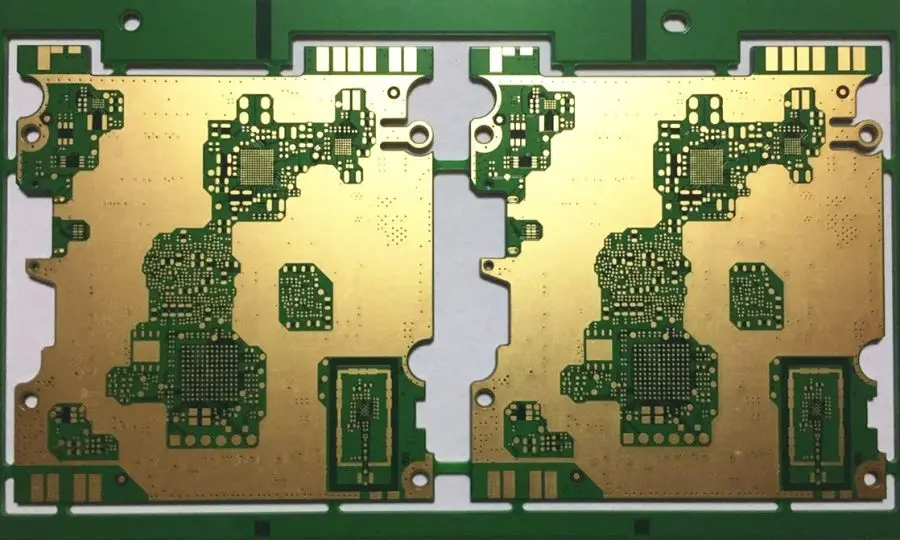

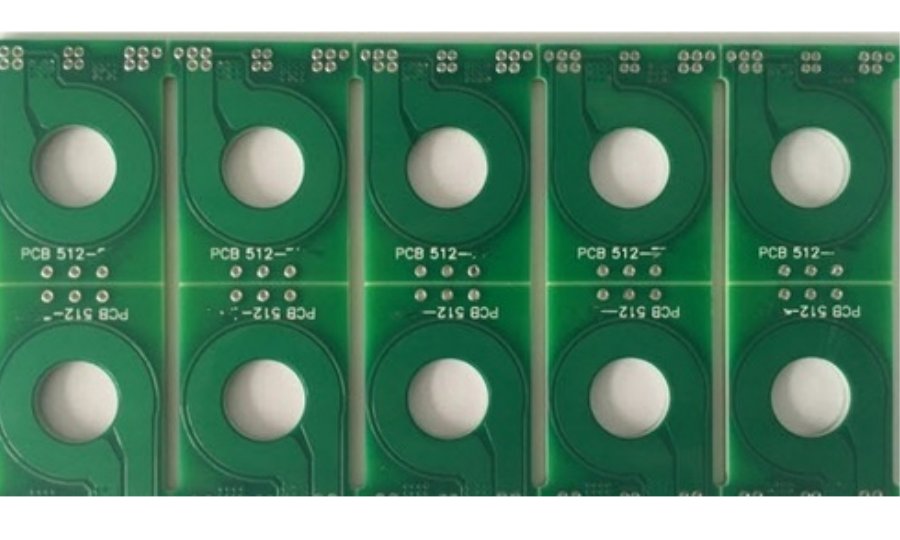

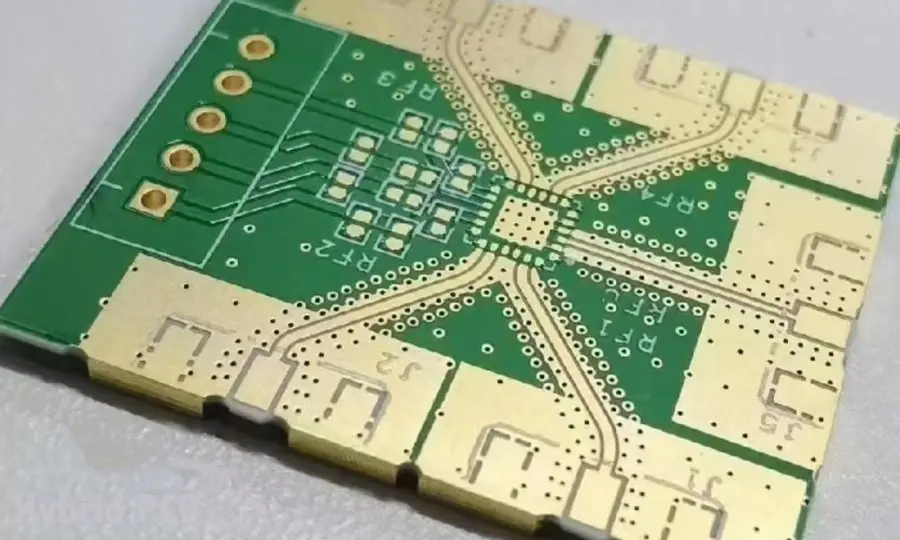

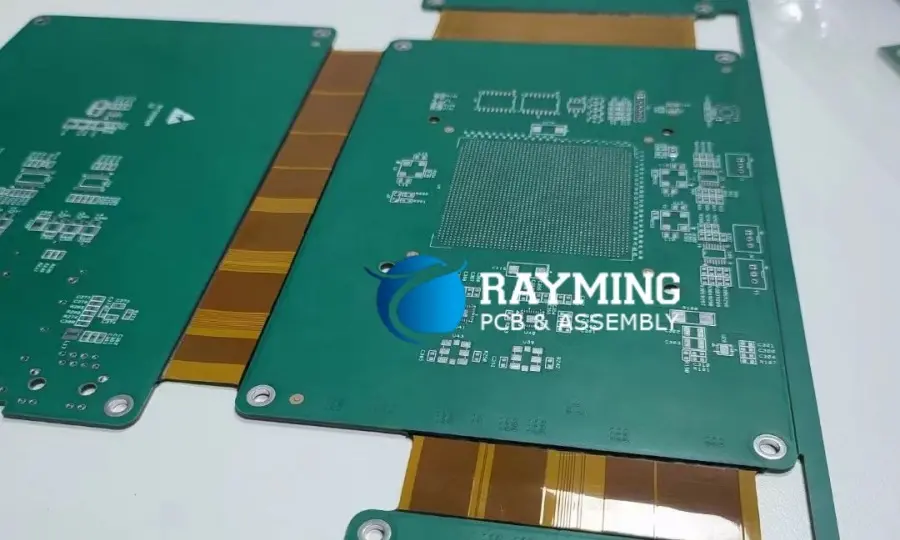

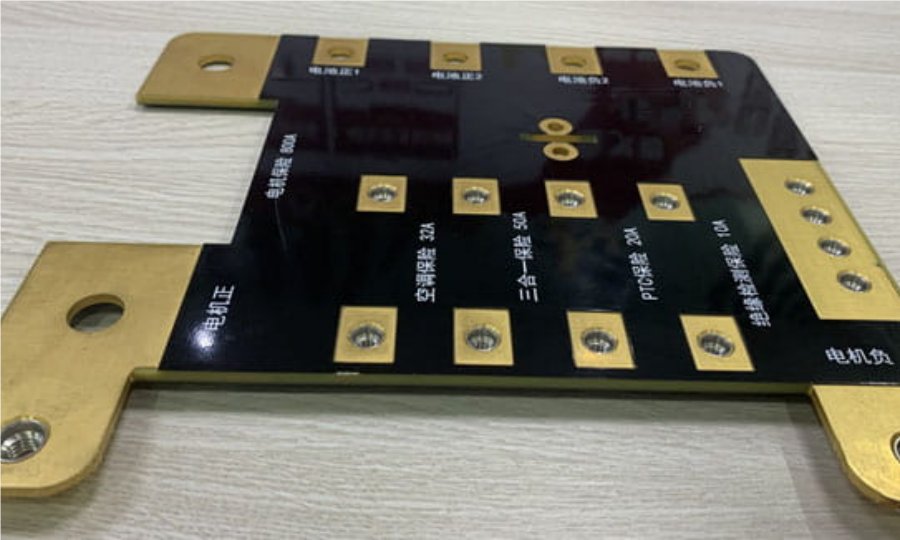

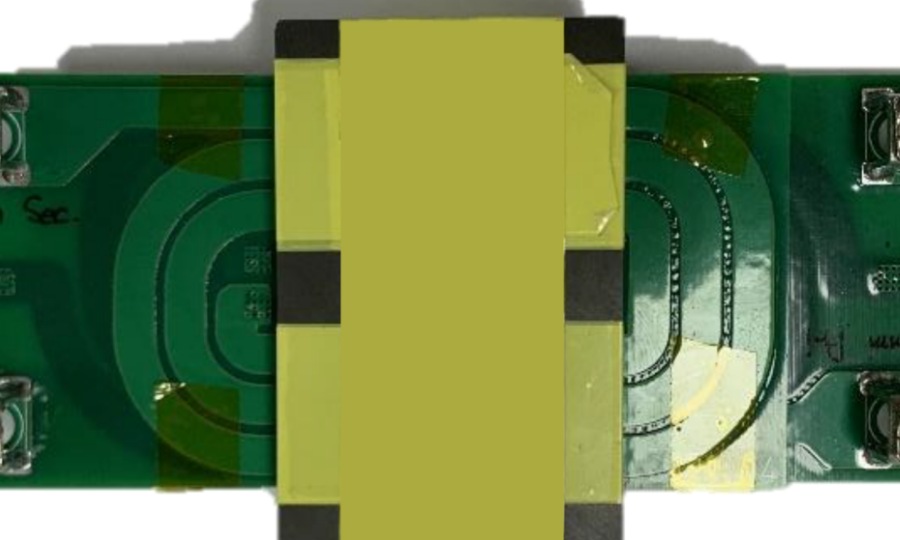

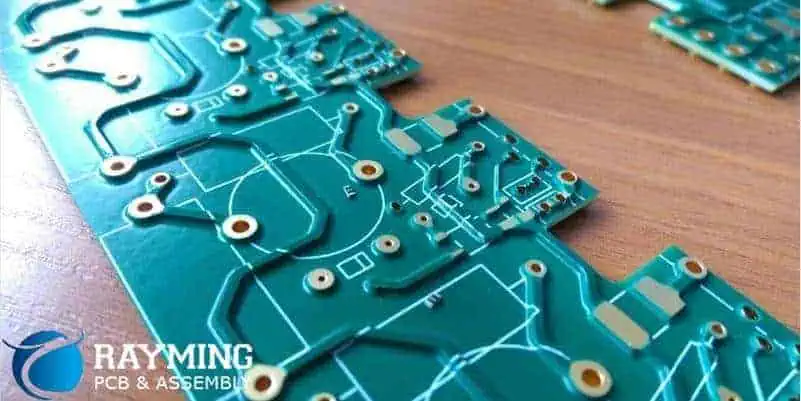

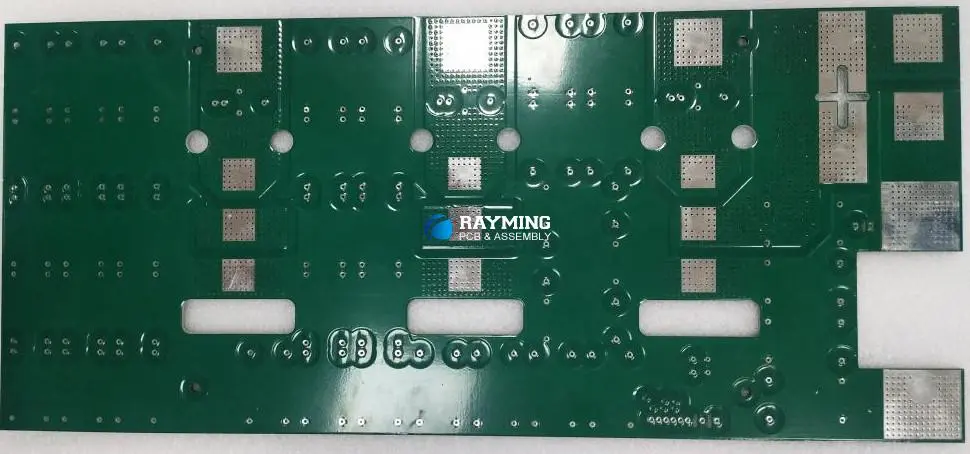

Heavy Copper PCB We Served

Heavy Copper PCB vs Standard PCB

Understanding the fundamental differences between heavy copper and standard PCBs is crucial for making informed design decisions.

Current Carrying Capacity

The most significant advantage of heavy copper PCBs lies in their superior current-carrying capacity:

- Standard PCB (1 oz copper): Typically handles 10-30A depending on trace width

- Heavy Copper PCB (4 oz copper): Can safely carry 50-100A per layer

- Heavy Copper PCB (10 oz copper): Supports 100-500A current loads

Current Calculation Example: For a 5mm wide trace with a 20°C temperature rise:

- 1 oz copper: ~30A maximum current

- 4 oz copper: ~80A maximum current

- 10 oz copper: ~150A maximum current

Thermal Performance

Heavy copper PCBs excel in thermal management due to copper’s exceptional thermal conductivity (401 W/m·K):

- Heat dissipation improvement: 30-50% better than standard PCBs

- Hot spot reduction: 40-60% decrease in localized heating

- Component temperature reduction: 15-20°C lower operating temperatures

- Thermal resistance: Significantly reduced through thick copper planes

Mechanical Strength

The increased copper thickness provides enhanced mechanical properties:

- Durability: 20%+ lower failure rates in harsh environments

- Vibration resistance: Superior performance in high-vibration applications

- Connector reinforcement: Stronger pad adhesion and via integrity

- Thermal cycling endurance: Better resistance to expansion/contraction cycles

Heavy Copper PCB Calculator

RayPCB Engineering Tools

🔄 Copper Weight Converter

📊 Standard Copper Weights Reference

| Weight | mm | mils | µm | Type |

|---|---|---|---|---|

| 0.5 oz | 0.0175 | 0.69 | 17.5 | Standard |

| 1 oz | 0.035 | 1.38 | 35 | Standard |

| 2 oz | 0.070 | 2.76 | 70 | Standard |

| 3 oz | 0.105 | 4.13 | 105 | Heavy |

| 4 oz | 0.140 | 5.51 | 140 | Heavy |

| 6 oz | 0.210 | 8.27 | 210 | Heavy |

| 10 oz | 0.350 | 13.78 | 350 | Extreme |

| 20 oz | 0.700 | 27.56 | 700 | Extreme |

⚡ Current Carrying Capacity (IPC-2221)

📈 Current Capacity Comparison

For 100 mil trace width @ 20°C rise (External)

📐 Trace Width Calculator

🔍 Visual Trace Comparison

Trace width needed for 15A @ 20°C rise

🌡️ Thermal Resistance Calculator

📋 Thermal Properties Comparison

PCB Layer Stack Visualization

Heavy copper increases thermal mass and heat spreading capability

💰 Heavy Copper PCB Cost Estimator

📊 Cost Factors Breakdown

Relative cost impact of heavy copper vs standard PCB

Click on each tip to expand detailed design guidelines for heavy copper PCBs.

Minimum Trace Width: Heavy copper requires wider minimum traces due to etching undercut. For 3oz copper, minimum trace is typically 8-10 mils; for 6oz, it's 12-15 mils; for 10oz+, expect 20+ mils minimum.

Spacing Rules: Increase spacing proportionally with copper weight. Use 1:1 ratio as a starting point (trace width = spacing). For high voltage, increase spacing per IPC-2221 guidelines.

Tip: Design with 20% margin above minimums to improve yield and reduce cost.

Via Size: Use larger vias for heavy copper (minimum 0.4mm drill for 3oz, 0.5mm for 6oz+). The aspect ratio (board thickness/hole diameter) should not exceed 8:1.

Via Arrays: For high current, use multiple vias in parallel. Calculate total current capacity as sum of individual via capacities minus 20% for thermal coupling.

Thermal Vias: Place thermal vias directly under heat-generating components with 0.3-0.5mm pitch. Fill with solder or conductive epoxy for best thermal transfer.

Symmetrical Design: Always use symmetrical copper distribution to prevent board warping. If outer layers are 4oz, balance with inner power/ground planes.

Prepreg Selection: Use high-resin content prepreg (≥60%) to fill the gaps caused by thick copper features. Multiple prepreg sheets may be needed.

Mixed Copper: Consider using heavy copper only where needed (power paths) and standard copper for signal layers to optimize cost and manufacturability.

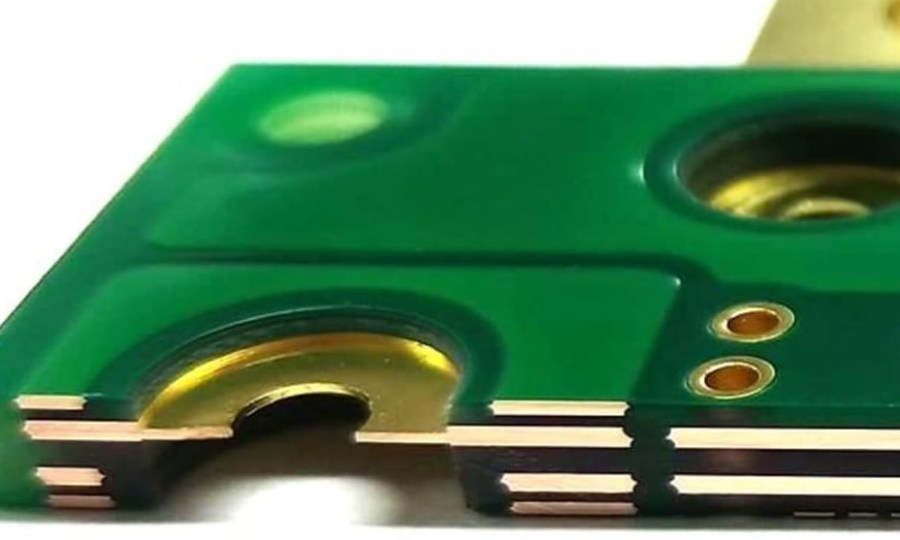

Coverage Challenges: Heavy copper creates significant height differences. Standard solder mask may not adequately cover trace edges, leading to exposed copper.

Solutions: Request multiple solder mask coats, use liquid photoimageable (LPI) solder mask, or consider selective solder mask with exposed copper planes for better thermal performance.

Design Rule: Increase solder mask clearance by 2-3 mils per ounce of copper above 2oz to account for registration challenges.

Copper Planes: Maximize copper pour areas for heat spreading. Use polygon pours connected to power components. Avoid isolated copper islands that can't dissipate heat.

Component Placement: Distribute heat sources evenly. Keep high-power components away from board edges where heat can't spread in all directions.

Airflow: Orient traces parallel to expected airflow direction. Place thermal relief patterns on pads connected to large copper areas for reliable soldering.

Undercut Effect: Thick copper etches more at the base than the top, creating trapezoidal trace profiles. Plan for ~1mil undercut per ounce of copper on each side.

Compensation: Work with your fab to determine etch compensation factors. Typically add 0.5-1.0 mils per ounce to designed trace widths.

Isolation: Large copper areas may need isolation slots or breakup patterns to ensure complete etching and prevent shorts from bridged copper.

Panelization: Heavy copper boards need larger panel margins and breakaway tabs due to increased mechanical stress during depaneling.

Tooling Holes: Use larger tooling holes (≥3.2mm) with adequate clearance from copper features to prevent damage during handling.

Documentation: Clearly specify copper weights for each layer in fab notes. Include cross-section drawings for complex stackups. Communicate current requirements to help fab optimize the design.

Electrical Testing: Request 100% electrical testing for heavy copper boards due to higher risk of shorts from etching challenges.

Cross-Section Analysis: For critical applications, request cross-section samples to verify copper thickness, via plating quality, and layer registration.

Thermal Cycling: Heavy copper PCBs may experience different thermal expansion. Consider thermal cycling tests for high-reliability applications to verify long-term solder joint integrity.

🏭 RAYPCB Heavy Copper Capabilities

📦 Applications & Lead Times

Typical Applications

- Power converters & inverters

- Electric vehicle (EV) systems

- Solar inverters & renewable energy

- Motor drivers & controllers

- High-power LED lighting

- Welding equipment

- Power distribution systems

- Industrial controls

- Battery management systems

- UPS systems

Estimated Lead Times

Key Benefits and Advantages

1. Superior Current Handling

Heavy copper PCBs can handle continuous high-current loads without the voltage drops and heating issues common in standard PCBs. This capability is essential for:

- Power supply circuits requiring 100+ amp capacity

- Motor drive applications with peak currents exceeding 200A

- Battery management systems in electric vehicles

- High-power LED lighting systems

2. Enhanced Thermal Management

The thick copper layers act as integrated heat spreaders, eliminating the need for external thermal management solutions in many applications:

- Built-in heat sinking: Copper planes distribute heat across the entire board

- Reduced hot spots: Even temperature distribution prevents component failure

- Lower operating temperatures: Extended component lifespan and improved reliability

- Simplified cooling: Reduced dependency on fans and heat sinks

3. Space and Weight Optimization

Heavy copper technology enables more compact designs by:

- Layer count reduction: Single heavy copper layer replaces multiple standard layers

- Component integration: High-power and control circuits on the same board

- Footprint minimization: 60% space reduction in power management systems

- Weight savings: Despite thicker copper, overall system weight often decreases

4. Improved Signal Integrity

For high-frequency applications, heavy copper provides:

- Lower impedance: Reduced signal loss and improved transmission

- Minimized crosstalk: Better isolation between signal paths

- Enhanced EMI performance: Copper planes provide superior shielding

- Consistent performance: More stable electrical characteristics

5. Cost-Effectiveness

While initial PCB costs are higher, heavy copper boards offer long-term savings through:

- Reduced assembly complexity: Fewer external components required

- Lower failure rates: Improved reliability reduces maintenance costs

- Simplified thermal management: Eliminates need for additional cooling systems

- Extended product lifespan: Better durability in harsh environments

Applications and Industries

Power Electronics

Heavy copper PCBs are fundamental to modern power electronics:

Power Supplies and Converters

- AC-DC and DC-DC converters for industrial applications

- Switch-mode power supplies requiring high efficiency

- Uninterruptible Power Supply (UPS) systems

- Power factor correction circuits

Motor Drives and Controls

- Variable frequency drives (VFDs) for industrial motors

- Servo motor controllers requiring precise current control

- Electric motor starter circuits

- Regenerative braking systems

Renewable Energy Systems

- Solar inverters converting DC to AC power

- Wind turbine power conditioning systems

- Energy storage system controllers

- Grid-tie inverters for distributed generation

Automotive Industry

The automotive sector, particularly with electrification trends, heavily relies on heavy copper PCBs:

Electric Vehicle Components

- Battery Management Systems (BMS) handling 400-800V systems

- On-board chargers with power levels up to 22kW

- DC-DC converters for 12V system power

- Traction inverters for electric motor control

Advanced Driver Assistance Systems (ADAS)

- Radar and lidar power supplies

- Camera processing units with high-power processors

- Electronic control units (ECUs) for autonomous functions

- Sensor fusion processing systems

Traditional Automotive Applications

- Electronic power steering modules

- Engine control units for high-performance applications

- LED headlight and taillight controllers

- Infotainment system power management

Military and Aerospace

Mission-critical applications demand the reliability of heavy copper PCBs:

Defense Systems

- Radar transmitter power supplies

- Electronic warfare equipment

- Communications systems for harsh environments

- Missile guidance and control systems

Aerospace Applications

- Satellite power distribution systems

- Aircraft power conversion units

- Avionics systems requiring high reliability

- Space-qualified electronics for extended missions

Industrial Applications

Heavy-duty industrial equipment benefits from heavy copper PCB technology:

Process Control Systems

- Industrial automation controllers

- Process monitoring and control equipment

- Safety systems for hazardous environments

- Data acquisition systems for harsh conditions

Manufacturing Equipment

- CNC machine controllers

- Robotic system power supplies

- Welding equipment power systems

- Injection molding machine controls

Telecommunications

High-power telecommunications equipment utilizes heavy copper PCBs:

- Base station power amplifiers

- Microwave communication systems

- Fiber optic equipment power supplies

- Emergency communication systems

Design Considerations

Electrical Design Parameters

Current Capacity Calculations Use IPC-2221 guidelines or specialized calculators to determine required copper thickness:

I = 0.048 × ΔT^0.44 × W × Th^0.725Where:

- I = Current (Amps)

- ΔT = Temperature rise (°C)

- W = Trace width (mils)

- Th = Copper thickness (mils)

Trace Width and Spacing Heavy copper requires increased minimum dimensions:

| Copper Weight | Min Trace Width | Min Spacing | Typical Via Size |

|---|---|---|---|

| 3 oz (105μm) | 8-10 mils | 6-8 mils | 12-16 mils |

| 6 oz (210μm) | 12-15 mils | 12-15 mils | 16-20 mils |

| 10 oz (350μm) | 20-25 mils | 20-25 mils | 24-32 mils |

Thermal Management Design

Material Selection Choose substrates with appropriate thermal properties:

- High-Tg materials: FR4-TG170+ for temperatures >130°C

- Low CTE materials: <17 ppm/°C to minimize thermal stress

- Polyimide substrates: For extreme temperature applications

- Ceramic substrates: For maximum thermal conductivity

Thermal Relief Design Implement proper thermal relief patterns for:

- Component pads to prevent heat-related soldering issues

- Via connections to balance thermal and electrical performance

- Copper pour connections to minimize thermal resistance

- Ground plane connections for optimal heat spreading

Mechanical Design Considerations

Board Stackup Design

- Balance copper distribution across layers to prevent warping

- Consider Z-axis expansion with temperature changes

- Plan for increased board thickness with heavy copper layers

- Design symmetrical stackups when possible

Via Design and Placement

- Use larger via sizes to accommodate thicker copper plating

- Implement via-in-pad designs for high-current applications

- Consider thermal vias for heat transfer to external heat sinks

- Plan via placement to minimize thermal resistance paths

Manufacturing Process

Fabrication Challenges

Etching Process Manufacturing heavy copper PCBs requires specialized etching techniques:

Differential Etching

- Controls removal rates for varying copper thicknesses

- Prevents over-etching of thinner features

- Maintains trace geometry and sidewall quality

- Enables mixed copper weights on single panels

Multiple Etch Cycles

- Sequential etching passes for uniform results

- Chemical concentration management between cycles

- Temperature control for consistent etch rates

- Inspection between cycles to prevent defects

Step Plating Process

- Incremental copper buildup in multiple stages

- Improves layer uniformity and reduces internal stress

- Achieves consistent via wall copper thickness

- Enables high-aspect-ratio via designs

Advanced Manufacturing Techniques

Specialized Equipment Requirements

- High-speed plating lines for thick copper deposition

- Advanced etch-back systems for profile control

- Precision drilling equipment for thick boards

- Automated optical inspection (AOI) for quality control

Process Control Methods

- Real-time monitoring of plating thickness

- Chemical analysis and adjustment systems

- Temperature and timing precision control

- Statistical process control (SPC) implementation

Quality Assurance Measures

- Microsection analysis for copper distribution

- Electrical testing for current capacity verification

- Thermal cycling tests for reliability validation

- Mechanical stress testing for durability confirmation

Lamination Process

Challenges in Lamination

- Increased pressure requirements for thick copper bonding

- Extended cure cycles for complete resin flow

- Temperature profile optimization to prevent delamination

- Void prevention in high-copper-density areas

Solutions and Techniques

- Multiple prepreg layers with optimized resin content

- Specialized brown oxidation treatments for adhesion

- Vacuum lamination to eliminate trapped air

- Post-lamination stress relief processes

Cost Analysis

Cost Factors

Material Costs

- Copper foil costs scale directly with thickness

- Substrate material premiums for high-temperature ratings

- Prepreg cost increases for specialized formulations

- Surface finish considerations for thick copper compatibility

Manufacturing Costs

- Extended processing times for etching and plating

- Specialized equipment and tooling requirements

- Increased scrap rates during process development

- Quality control and testing overhead

Volume Considerations

- High-volume production reduces per-unit costs

- Setup costs amortized across production runs

- Material purchasing power for large quantities

- Process optimization benefits with experience

Cost-Benefit Analysis

Initial Investment vs Long-term Savings

- Higher PCB costs offset by system-level savings

- Reduced external component requirements

- Simplified assembly processes

- Lower warranty and maintenance costs

Total Cost of Ownership (TCO)

- Extended product lifespan reduces replacement costs

- Improved reliability decreases field service requirements

- Enhanced performance may justify premium pricing

- Energy efficiency improvements provide ongoing savings

Selection Guidelines

When to Choose Heavy Copper PCBs

Current Requirements

- Continuous currents exceeding 30A per trace

- Peak currents above 50A in switching applications

- Multiple high-current paths on single board

- Current density requirements >1A/mm²

Thermal Requirements

- Component junction temperatures >100°C

- Power dissipation >50W without external cooling

- Thermal cycling requirements exceeding standard limits

- Heat spreading requirements across large areas

Environmental Conditions

- Operating temperatures beyond standard PCB limits

- High-vibration or mechanical stress environments

- Extended operational life requirements (>10 years)

- Mission-critical applications where failure is not acceptable

Manufacturer Selection Criteria

Technical Capabilities

- Copper weight range capabilities (up to required thickness)

- Layer count capabilities for complex stackups

- Minimum feature size specifications

- Quality certifications (IPC Class 2/3, military standards)

Experience and Expertise

- Portfolio of similar applications

- Engineering support capabilities

- Problem-solving track record

- Customer references and case studies

Manufacturing Infrastructure

- Specialized equipment for heavy copper processing

- Quality control systems and testing capabilities

- Capacity for required production volumes

- Geographic location and logistics considerations

Future Trends

Technology Evolution

Extreme Copper Applications

- Push toward 30+ oz copper weights for specialized applications

- Integration with advanced substrate materials

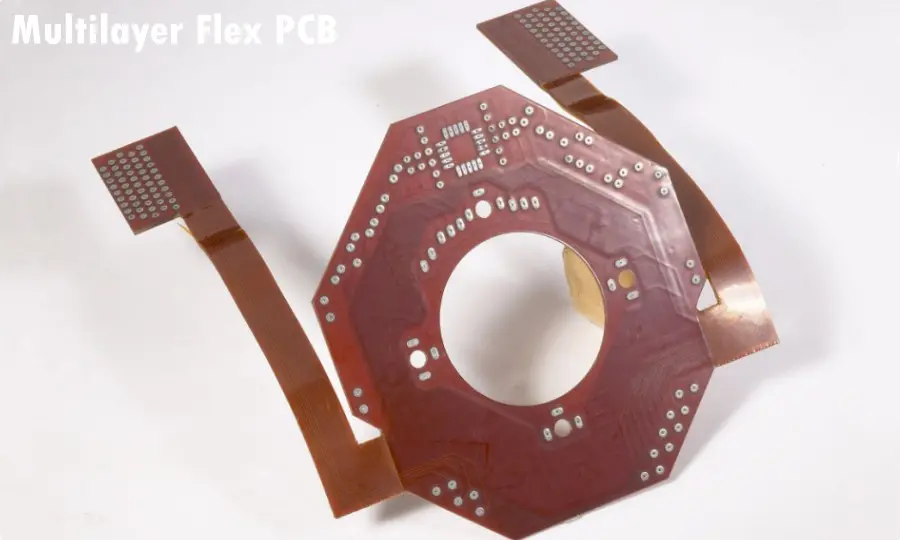

- Hybrid flexible-rigid heavy copper designs

- 3D printed copper integration possibilities

Manufacturing Innovations

- Additive manufacturing techniques for copper deposition

- Advanced plating chemistries for improved uniformity

- Automated process control with AI/ML optimization

- Real-time quality monitoring and feedback systems

Market Drivers

Electric Vehicle Growth

- Increasing power requirements for faster charging

- Higher voltage systems requiring better thermal management

- Integration of power electronics in compact spaces

- Demand for lightweight, high-performance solutions

Renewable Energy Expansion

- Grid-scale energy storage systems

- High-efficiency power conversion requirements

- Harsh environment applications (offshore wind, desert solar)

- Distributed energy resource management

Industrial Automation

- Industry 4.0 driving higher power densities

- Robotic systems requiring precise control

- IoT devices with power management requirements

- Edge computing applications with thermal challenges

Emerging Applications

Advanced Computing

- High-performance computing thermal management

- Cryptocurrency mining equipment

- Edge AI processing units

- Quantum computing support systems

Medical Technology

- High-power medical imaging equipment

- Surgical robot power systems

- Portable medical device power management

- Life-critical monitoring systems

Aerospace Innovation

- Electric aircraft propulsion systems

- Satellite power distribution advancement

- Space exploration equipment

- High-altitude platform systems

Conclusion

Heavy copper PCB technology represents a critical advancement in printed circuit board design, enabling unprecedented current-carrying capacity and thermal management for demanding applications. As industries continue to push the boundaries of power density and performance requirements, heavy copper PCBs provide the foundation for next-generation electronic systems.

The key to successful heavy copper PCB implementation lies in understanding the unique design considerations, manufacturing challenges, and application requirements. By working closely with experienced manufacturers and following established design guidelines, engineers can leverage heavy copper technology to create robust, reliable, and high-performance electronic systems.

Whether you’re designing power electronics for electric vehicles, renewable energy systems, or industrial automation equipment, heavy copper PCBs offer the performance characteristics necessary to meet today’s demanding requirements while providing a pathway for future technological advancement.

The investment in heavy copper PCB technology pays dividends through improved reliability, enhanced performance, and simplified system design, making it an essential consideration for any high-power electronic application.