Most conventional or traditional PCBs are rigid, which means that when in operation, they shouldn’t bend. Stretchable and flexible PCBs are required because many applications require a board to repeatedly bend or flex, which is a requirement for many applications. On closer inspection, a wide variety of newly developed parts, gadgets, and electronic components strongly demonstrate mechanical stretch ability.

Some of these include uses for curved surfaces, like those in the automobile industry, or flexible connections, like those in mobile phones. This page provides examples of a variety of stretchable PCB-related topics, including their composition, characteristics, mechanism, benefits, applications, and expected future developments.

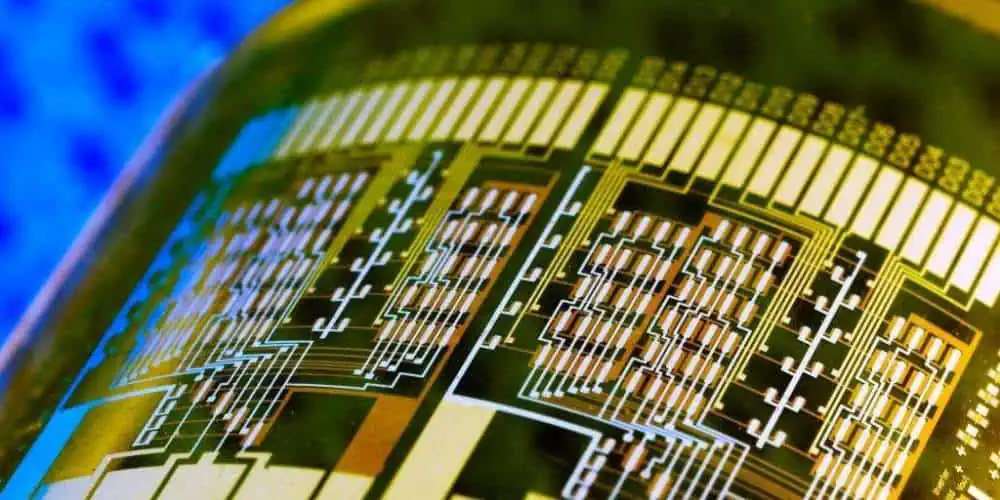

Design/Construction Of Stretchable Circuit Board

The substrate is Polyimide or Polyurethane, even though flexible PCB technology uses standard manufacture and subsequent assembly methods. Stretchable PCBs may be made with polyurethane or polyimide at a substantially lower cost than other materials. A large number of manufacturers use the following techniques to swiftly construct the substrate’s component parts.

Locally applied special coatings or interposers are the major methods used by manufacturers to strengthen the laminate. The most effective strategy, however, makes use of a technique called Stretch-Rigid. Stretch-Rigid connects two stiff boards without the need for a flexible PCB, as opposed to Rigid-Flex architecture, which performs less well.

The technology of Stretch-Rigid connects various rigid boards utilizing substrates that can be stretched and include integrated copper connectivity traces. Afterward, the electronic components are only soldered on such sturdy sections.

Advantages Of Stretchable Circuit Board

Stretchable Printed Circuit Boards are specifically made to be more flexible and save space in order to accommodate mounting designs with high density and lower footprints. Moreover, it aids in simplifying the assembling process while also boosting dependability. In short, the only approach that guarantees electrical device mobility and downsizing is flexible PCBs.

Stretchable circuit boards provide a number of benefits that are worth highlighting. Stretchable PCBs, for instance, may be pushed, stretched, and twisted without putting the conductor in danger. Moreover, flexible PCBs allow for a variety of shapes and custom-packed sizes.

Not just that. Excellent electrical conductivity is offered by flexible PCBs. They have a low dielectric constant which allows for electrical signal transmission, and outstanding thermal characteristics, which facilitate cooling. Furthermore, unlike hard PCBs, stretchy PCBs can function effectively in high temperatures.

Due to fewer internal connections, stretchable PCBs offer better assembly output and dependability. Additionally, as this PCB was created or built for one-way assembly, there was a little mistake during construction. Stretchable boards may easily change locations while being permanently electrically connected to one another.

Some other effective benefits of using flexible PCBs rather than rigid PCBs are as follows:

- Outstanding Thermal conductivity

- It lets Weight and occupies less space

- Meet all the requirements of transformation due to flexibility.

- Enhanced reliability and repeatability

- Reduce the prices of the overall assembly.

- Goes with connectors

- Excellent electrical conductivity and high speed

Mechanism Of Stretchable Printed Circuit Board

Copper traces prevent the stretchy PCB substrate made of the thermoplastic polyurethane that manufacturers employ from spreading. This is due to the fact that copper isn’t really sufficiently bendable for these uses.

Producers bind RA copper foil or conventional ED on the polyurethane base using their own lay-up methods and specialized presses. After finishing this stage, they build the stretchy circuits using customary subtractive wet-etching PCB procedures.

Stretchability is reduced when polyurethane base and adhesive are added in many layers. Hence most stretchy Printed Circuit Boards are double-layered or have a maximum of four layers. To ensure a consistent elastomer design, manufacturers add polyurethane solder covers on completed Boards.

Stretchable PCBs are put together using standard, surface mounting parts that are soldered to the copper rails. The locations where the elements are positioned cannot be stretched since the pieces are stiff. Stretchable PCBs are essentially some tiny, rugged islands that house sparse SMD components. On stretchy substrates, some conductive paper foil is used to link these SMD components.

Designers gave the copper traces on the substrate a funnel form to guarantee that they may flex or twist without being damaged. The horseshoe forms are then alternately positioned at 180◦ c to enable them to wander along a route that straight markings would have followed. While alternative methods, including triangular forms, can stretch, they do so with high amounts of stress and with reduced dependability.

Due to the aforementioned, many manufacturers like the horseshoe form, leading most of them to standardize it.

Top Uses Of Stretchable Circuit Board

Stretched PCBs are typically used in bending or irregularly shaped surfaces. These are some of the major applications for stretchy PCBs. It is clear that stretchy PCBs and such applications are both growing. On incorporated surfaces, such as implantable or wearables devices, a standard rigid PCB cannot be conveniently positioned or used.

Equipment and parts utilized in biological applications, safety, sports, and leisure frequently have asymmetrical shapes. A PCB must adhere to the form necessary for effective integration, even with such erratic forms. Stretchable circuits may readily adapt to any area, whilst flexible circuit shapes like a cone or cylinder can be created.

Having stated that, stretchy PCBs are utilized in a wide range of applications, including consumer garments, precise positioning, and medical devices. For instance, integrated sensors on stretchy PCBs can be used to monitor pressure inside the sole of a shoe. By gathering user information based on unrestricted mobility, they do this.

Moreover, since they have pressure sensors placed in them that can accurately assess the contact pressure, stretchable PCBs are inserted within bandages. It is extremely useful to be able to monitor contact pressure, particularly when treating open wounds.

Conclusion

Stretchable PCBs are used extensively in a wide variety of electronic gadgets to give comfort as one of their distinctive features. There are several benefits that flexible PCBs may provide that rigid PCBs cannot. Stretchable PCBs is expected to see unprecedented levels of utilization based on predicted future trends.