Chemicals called soldering flux are used both before and after soldering electrical components. Both automated and manual soldering procedures can be carried out using soldering flux. In order to clean and remove any impurities or oxides from these metal surfaces prior to soldering, soldering flux can be mostly used.

Whenever metals get exposed to air, chemical compounds known as oxides are created. A flawless solder joint cannot form within existence of oxides. Metal oxides may cause electrical conductivity as well as inefficient electricity flow across electrical boards or circuit boards, which may be present on circuit boards. Solder flux is also used for the following reasons:

- Prevent the metal’s surface from reoxidizing while soldering.

- Assist in lowering the viscosity and surface tension of such molten solder. It enhances the wettability.

- This flux enables this molten solder that permanently unites two mechanical and electrical components.

How do I choose the right soldering flux?

Halides are the foundation of fluxes’ method of activity. Higher halide content present in the flux will improve performance by eliminating any generated metal oxide upon that metal surface thus strengthening the joint. High activity fluxes frequently leave corrosive residues on that soldering surface. It might lead to issues with the product’s dependability.

Two things need to be taken into account when performing electronic assembly.

Before as well as after the soldering, the flux must be inactive. Secondly, this should stay operational for the whole soldering procedure. This aids in preventing the oxides and tarnish that can build because of high temperatures used when soldering.

To keep the surface for soldering ready for the soldering, proper soldering iron fluxes should operate just beneath the temperature for soldering temperature. Extremely active flux also isn’t advised because to the undesirable by-products which cause reliability problems.

The fundamental drawback of these fluxes is they are ineffective even during high temperatures. There are currently neither clean fluxes available to address this issue. Activity and cleanability should be balanced in a good solder flux. The majority of non-clean fluxes lack halides. The primary component of them is organic acid.

How is soldering flux used?

Solder flux is available as a liquid or paste. While the changes in the liquid are held in flux pens or bottles, the majority of solid flux are kept in tiny jars or tins. Use all safety preventive equipment when soldering to improve your security. A breakdown on how to utilize a soldering flux is provided below.

Use the right solvent to clean your metal surface. This aids in cleaning out dirt, grime, and certain metal oxides that may have built up upon that soldering surface. Apply a thin, even layer of flux onto the surface for soldering. At this point, you just aren’t permitted to warm the surface.

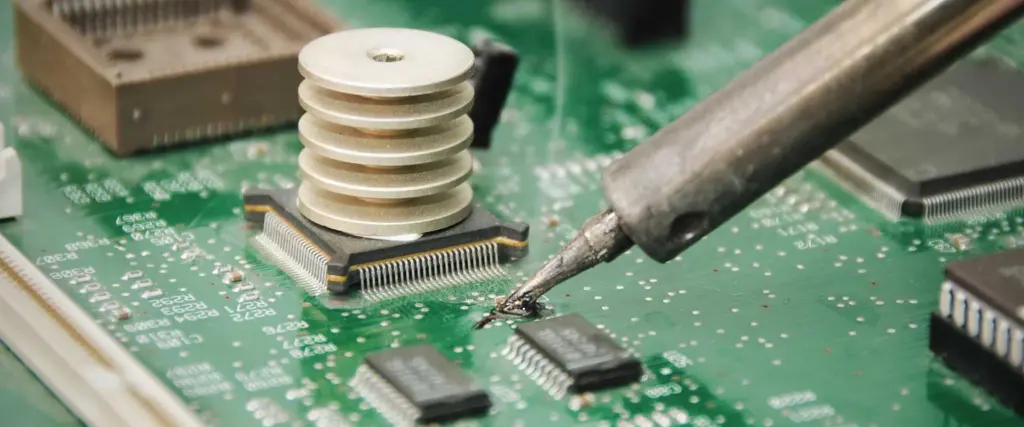

Place a soldering gun on these metal plates coated with the flux when it is sufficiently hot. All metal oxides must be eliminated by melting the flux with a soldering gun and spreading it over the entire metal surface. Once this flux has dissipated, add a soldering wire. By doing this, its solder will bond prior to reoxidation.

Solder Flux Types

Inside the electronics sector, soldering flux comes in three main varieties. An outline of each is provided below.

Rosin Flux

The oldest form of flux is rosin flux. Natural resins from pine trees are used to make the flux. To improve performance, present day rosin flux gets combined with other fluxes. This kind of flux generally flows easily, particularly in warm temperatures. Both foreign materials and metal oxides are eliminated by the flux.

Although resin flux appears naturally acidic, once it has solidified, it turns inert and can be kept on soldering surfaces without having to endanger the circuit. It is advised to remove the flux when soldering is done because this circuit could warm up as well as liquefy any flux.

Organic acid Flux

Water-soluble flux is another name for this soldering flux. These organic acids, including stearic, lactic, and citric acid, are used to make this sort of flux. After that, organic solvents like isopropyl or alcohol are added to the acids.

Metal oxides can be removed more successfully using organic acid fluxes. Additionally, it is simple to clean and has strong soldering activity. Never leave organic acid flux on any soldering surfaces, particularly circuit boards. Soft soldering is the major application for this soldering flux.

Inorganic Acid Flux

Brass, copper, and stainless steel are stronger metals that perform well with this soldering flux. You must carefully clean your soldering surface then get rid of any corrosive remnants before employing inorganic flux. Last but not least, non-electrical soldering can be done using inorganic acid flux.

Applications of Soldering Flux

Flux might be in the form of a solid, liquid, or paste form. Depending on the soldering method being used, it could be applied to a Circuit board in a variety of ways:

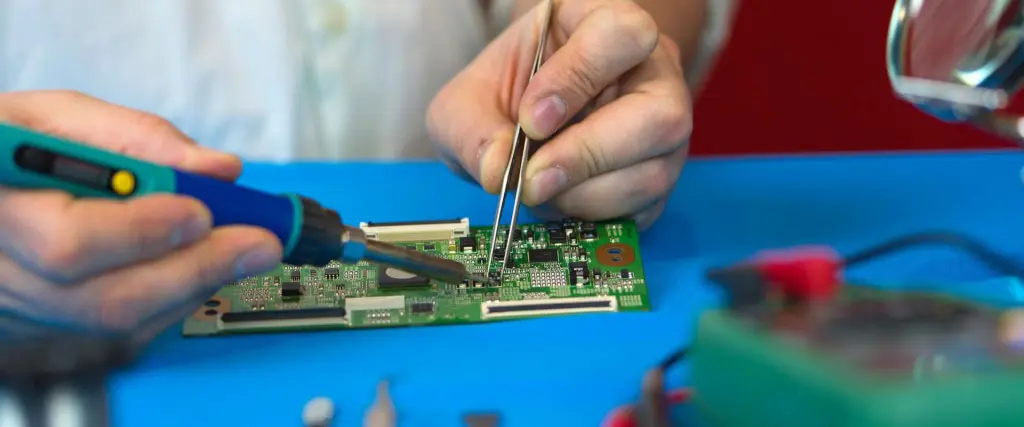

Hand soldering: This involves manually applying flux. You can use handmade applicators or solder pens. Some soldering wire types are made with flux and solder together. If so, melting the wire onto the surface having the soldering iron would cause the flux to dissolve.

Wave soldering: Prior to the board traveling via solder wave, flux gets sprayed on it.

Reflow Soldering: When reflow soldering, the flux gets applied as paste made of gooey flux as well as small metal solder spheres.

How do I use Soldering Flux?

Soldering flux can be purchased in the form of paste in tiny jars or tin cans, liquid in bottles or jars, as well as flux pens. Organic flux, which is primarily used during soft soldering, while inorganic flux that is acid-based may be employed in different non-electrical applications. As a result, flux utilized for brazing and soldering is typically inorganic; however, this may comprise organic chemicals that become active at extremely high temperatures.

Utilize solder flux as described below:

Before applying your soldering flux, users should clean any metal contact using a reliable solvent to get rid of any possible dirt, grime, and excessive oxidation.

The surfaces in which this actual soldering will take place must next be covered evenly with the flux. You should be aware that it cannot heat during this point.

As soon as the soldering gun’s tip is ready and hot, this should be put on metal contacts that have been covered in flux. Until this flux is present, this should melt that flux, spread across the surface of the metal, and eliminate its oxide layer.

After the vaporization of the flux, this should introduce as well as melt its soldering wire, ensuring this solder bonds even before oxidizing goes on again to ensure that the soldering is effective.

Soldering Flux Alternatives

Any substitutes for soldering flux? Although you may solder without flux, you still require something to remove the metal surface’s oxides. Unless you do this, you risk damaging the surface as well as leaving it poorly cleaned while soldering. Petroleum jelly can be described as a natural anti-corrosive option to the soldering flux that won’t harm your circuit board or material.

Soldering flux should be used to guarantee a solid bond that won’t short out or corrode. No matter how thoroughly you clean that metal surface, a flux is still required in order for the solder to attach. Soldering flux is advised since without it, the solder junction just won’t be sturdy or conducting enough.

Moreover, solder will follow a source of heat, and without the soldering flux, it could be challenging to remove any molten solder from your iron.

Why Do We Use Solder Flux When We Solder?

Flux’s primary application in any circuit board rework or assembly is to clean as well as remove all oxides and contaminants from the PCB. Due to the oxides that have been deposited onto the board, it might have poor solder joints, which would result in an electrical conduction that is poor coupled with poor flow via the circuit.

The effects of soldering flux are favorable for both wetting, soldering, and deoxidizing metals (the copper tracks present on the circuit board as well as leads of the electronic components). By eliminating oxides as well as other surface impurities, the activators inside the flux encourage wetting of such molten solder onto the lands of the surface mount as well as component leads or terminations.

Cleaning the Soldering Flux

During the soldering procedure, it’s crucial to clean your board to get rid of any undesirable flux residue which might degrade the board’s functionality or even result in short circuits. There is no cleaning required for no-clean flux. Aqueous cleaners or solvent cleaning can be applied to fluxes that require cleaning following soldering. Most manufacturers of soldering flux also offer flux cleaners.

Conclusion

There can be no doubt that soldering flux plays a key role during electrical soldering. Metal oxides on soldering surfaces can be cleaned and removed with the use of soldering flux. In addition, soldering flux plays a huge role in the prevention of oxidation from the surfaces of the metal during soldering.