Optimize your electronic performance with expertly engineered thermal management PCB designs that ensure reliable operation and extended component lifespan.

Product Overview

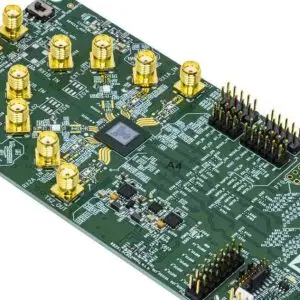

Our Thermal Management PCB Design service specializes in creating advanced heat dissipation layouts that effectively manage thermal challenges in high-power and high-density electronic applications. We employ cutting-edge thermal modeling and strategic component placement to deliver PCB solutions that maintain optimal operating temperatures while maximizing performance and reliability.

Key Features

Advanced Thermal Modeling & Analysis

- Comprehensive thermal simulation using industry-standard software

- Hotspot identification and temperature gradient mapping

- Thermal resistance calculations and heat flow optimization

- Real-time thermal performance validation

Strategic Heat Dissipation Techniques

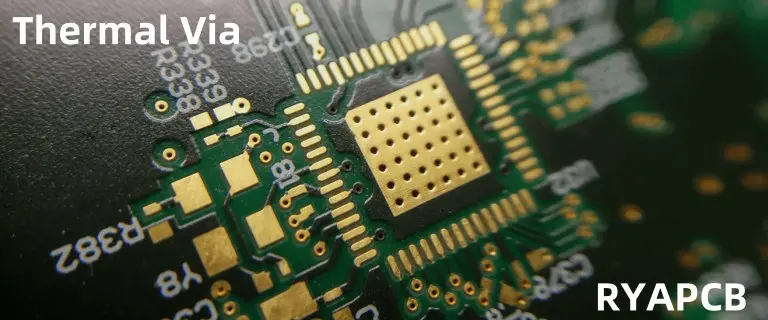

- Optimized copper pour and thermal via placement

- Multi-layer thermal spreading designs

- Integrated heat sink mounting solutions

- Thermal interface material (TIM) recommendations

Component-Centric Design Approach

- Power component thermal derating analysis

- Strategic placement of heat-generating components

- Thermal isolation between sensitive and high-power components

- Airflow optimization for natural and forced convection

Material Selection & Layer Stack-up

- High thermal conductivity substrate materials

- Metal core PCB (MCPCB) options for extreme applications

- Optimized copper thickness for thermal spreading

- Dielectric materials with enhanced thermal properties

Applications

- Power Electronics: Inverters, converters, motor drives

- LED Lighting: High-power LED arrays and drivers

- Automotive Electronics: Engine control units, battery management systems

- Industrial Controls: Variable frequency drives, power supplies

- Telecommunications: Base stations, power amplifiers

- Medical Devices: Imaging equipment, therapeutic devices

Technical Specifications

- Thermal Resistance: Optimized to <0.5°C/W junction-to-ambient

- Operating Temperature Range: -40°C to +125°C

- Power Density Support: Up to 50W/cm² heat dissipation

- Layer Count: 2-20 layers with thermal optimization

- Via Technology: Thermal vias, microvias, and filled vias

- Substrate Options: FR4, Rogers, aluminum, copper core

Design Process

Our systematic approach ensures optimal thermal performance through detailed analysis, simulation-driven design, and comprehensive validation. We collaborate closely with your engineering team to understand specific thermal requirements and constraints, delivering customized solutions that meet your exact specifications.

Quality Assurance

All thermal management designs undergo rigorous testing including thermal imaging verification, temperature cycling, and reliability stress testing to ensure consistent performance across the entire operating envelope.

Transform your thermal challenges into competitive advantages with our proven thermal management PCB design expertise.