Product Overview

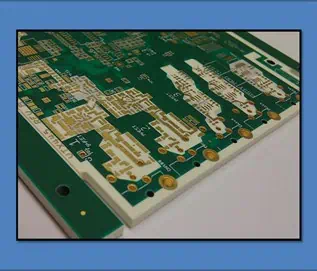

Rogers DiClad laminates are woven fiberglass reinforced PTFE-based composites designed for use as printed circuit board substrates in high frequency applications. The controlled fiberglass and PTFE content ratio enables DiClad laminates to offer a range of low dielectric constant (Dk) values.

Key Material Composition

DiClad laminates are PTFE with woven fiberglass composite materials used for PCB substrates. The unique blend of fibers and composite materials provides dissipation factor flexibility and low dielectric constant. Unlike the CuClad® laminate series, the DiClad laminates do not have cross plied constructions.

DiClad Series Variants

DiClad 870/880 Series

By using fewer plies of woven fiberglass and a higher ratio of PTFE content, the DiClad 870 and DiClad 880 laminates offer lower dielectric constants (Dk) and dissipation factors. The dielectric constant of Rogers DiClad 870/880 laminates is 2.60.

DiClad 527 Series

DiClad 527 laminates offer a higher ratio of fiberglass reinforcement to PTFE content. This carefully controlled ratio provides a higher dielectric constant.

Technical Performance Characteristics

Electrical Properties

- Low Dielectric Constant: Higher PTFE content provides a lower Dk and loss tangent, while higher fiberglass content provides better dimensional stability and registration.

- Frequency Stability: The stability of the Dielectric Constant of DiClad over frequency ensures easy design transition and scalability of design.

- Low Loss Tangent: Extremely Low Loss Tangent with Excellent Dimensional Stability

Physical Properties

- Dimensional Stability: Rogers DiClad 870/880 offers excellent temperature stability, low moisture absorption, and a uniform coefficient of thermal expansion.

- Thermal Performance: The thin metal cladding used in these laminates helps improve thermal stability.

- Panel Size: These laminates are available in sizes up to 48″ x 54″.

Key Benefits

Superior RF Performance

- Low dielectric constant for reduced signal losses

- Excellent frequency stability across the electromagnetic spectrum

- Electrical Properties are highly uniform across frequency

Manufacturing Advantages

- The materials are compatible with standard PTFE-based printed circuit board substrates.

- All of the boards are 100% electrical tested before shipment.

- Lead-free process compatible

Reliability Features

- Low moisture absorption

- Consistent Mechanical Performance

- These materials are ideal for use on high-reliability PCBs.

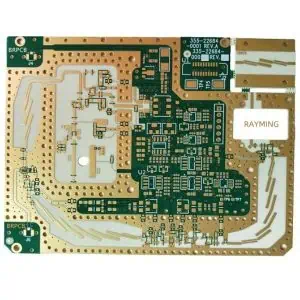

Target Applications

High-Frequency Electronics

- These materials are suitable for microwave and millimeter-wave applications.

- The high-frequency Rogers laminate is ideal for digital PCB applications requiring high-speed performance at 10 GHz.

Industry Sectors

- 5G Wireless Communication: ACS Materials are a consistent and reliable choice for applications including 5G wireless communication

- Automotive: automotive radar sensors

- Aerospace & Defense: aerospace, satellites

- RF/Microwave Systems: Rogers DiClad 870/880 an ideal choice for RF/microwave applications.

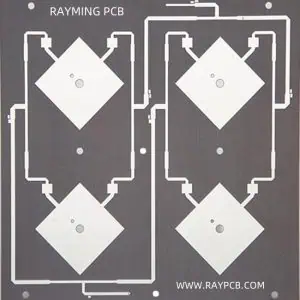

Manufacturing Specifications

Quality Standards

- The boards are manufactured as per IPC Class II standard.

- Product Performance Uniformity

Processing Compatibility

- Compatible with standard PCB fabrication processes

- Suitable for both prototype and production volumes

- Works with conventional copper plating and etching processes

Competitive Advantages

Rogers DiClad Woven Glass Substrates offer designers a superior alternative to traditional FR-4 materials for high-frequency applications, providing:

- Predictable Performance: Stable electrical properties across temperature and frequency ranges

- Design Flexibility: Range of dielectric constants to optimize circuit performance

- Manufacturing Reliability: Proven compatibility with standard PCB processes

- Cost-Effective Solution: Balance of performance and manufacturability for volume production

Summary

Rogers DiClad Woven Glass Substrates represent a proven solution for high-frequency PCB applications where signal integrity, dimensional stability, and manufacturing reliability are critical. The carefully engineered PTFE/woven glass composition delivers consistent electrical performance while maintaining compatibility with standard fabrication processes, making these materials ideal for next-generation RF, microwave, and high-speed digital applications.