Professional Grade Hydrocarbon/Ceramic Laminate for Advanced Electronics

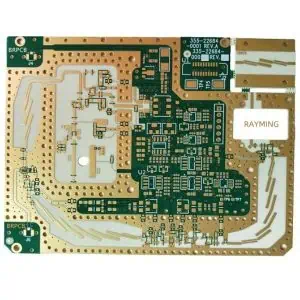

Rogers RO4350B is the industry-leading high-frequency printed circuit board material that delivers exceptional RF performance while maintaining cost-effectiveness for commercial applications. This advanced hydrocarbon/ceramic laminate combines the superior electrical properties of PTFE materials with the processing simplicity of standard FR4, making it the optimal choice for demanding RF and microwave applications.

Key Technical Specifications

- Dielectric Constant (Dk): 3.48 ± 0.05 @ 10 GHz

- Loss Tangent (Df): 0.0037 @ 10 GHz (remains <0.004 up to 77 GHz)

- Operating Frequency Range: 500 MHz to 77+ GHz

- Temperature Range: -50°C to +150°C

- Glass Transition Temperature (Tg): >280°C (536°F)

- Thermal Conductivity: Superior heat dissipation properties

- Z-axis CTE: 41 ppm/°C (low thermal expansion)

- Flame Rating: UL 94 V-0 compliant

Superior Performance Features

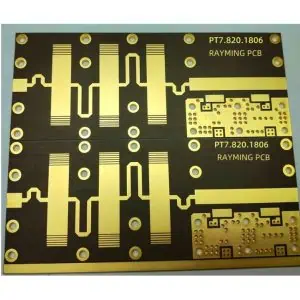

Exceptional Frequency Stability

RO4350B provides a stable Dk of 3.48 from 500MHz to over 40GHz with minimal variation versus frequency, ensuring consistent impedance control and signal integrity across the entire operational spectrum.

Ultra-Low Signal Loss

With an industry-leading loss tangent of 0.0037, RO4350B minimizes signal attenuation and maximizes power efficiency in critical RF applications.

Outstanding Thermal Performance

- High thermal conductivity for efficient heat dissipation

- TG in excess of 280°C (536°F), so their expansion properties remain stable at all process temperatures

- Excellent dimensional stability under thermal cycling

Cost-Effective Manufacturing

RO4350B uses standard FR4 circuit board processing technology to easily convert a series of laminates to printed circuit boards, eliminating the need for specialized PTFE processing techniques and reducing manufacturing costs.

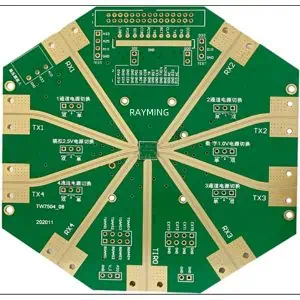

Primary Applications

5G & Telecommunications

- Cellular base station antennas and power amplifiers

- 5G wireless infrastructure components

- Microwave point-to-point (P2P) connections

Automotive & Transportation

- Automotive radar and sensor systems

- Advanced driver assistance systems (ADAS)

- Vehicle-to-everything (V2X) communication

Aerospace & Defense

- Military radar systems

- Satellite communication equipment

- Avionics and navigation systems

Industrial & Commercial

- Radio frequency identification (RFID) tags

- Industrial wireless sensors

- Medical device electronics

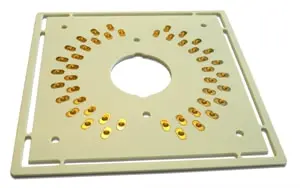

Available Configurations

Standard Thicknesses:

- 0.004″ (0.101mm) to 0.060″ (1.524mm)

- Common sizes: 0.010″, 0.020″, 0.030″

Panel Sizes:

- 12″ × 18″ (305 × 457mm)

- 24″ × 18″ (610 × 457mm)

- 24″ × 36″ (610 × 915mm)

- 48″ × 36″ (1.224m × 915mm)

Copper Foil Options:

- 0.5 oz to 3 oz copper weights

- Standard and reverse treat foils available

Design Advantages

Hybrid Construction Capability

RO4350B enables cost-effective multilayer designs by allowing combination with standard FR4 materials, providing high-frequency performance where needed while maintaining overall cost efficiency.

Reliable Via Performance

Low Z-axis coefficient of thermal expansion ensures reliable plated through-hole quality even in demanding thermal shock applications.

Standard Processing Compatibility

Unlike PTFE-based materials, RO4350B requires no special via preparation or sodium etching, streamlining the manufacturing process.

Quality & Compliance

- RoHS Compliant: Lead-free and environmentally friendly

- UL 94 V-0 Rated: Superior flame resistance for safety-critical applications

- ISO Certified Manufacturing: Consistent quality and reliability

- Tight Tolerances: ±0.05 dielectric constant control for predictable performance

Why Choose RO4350B?

Proven Performance: Trusted by leading electronics manufacturers worldwide for mission-critical RF applications.

Cost Optimization: Delivers high-frequency performance at a fraction of the cost of traditional microwave materials.

Manufacturing Efficiency: Compatible with standard PCB fabrication processes, reducing complexity and lead times.

Wide Frequency Range: Single material solution for applications from 500 MHz to 77+ GHz.

Thermal Reliability: Maintains stable performance across extreme temperature ranges.

Industry Recognition

Rogers RO4350B has become the industry standard for cost-effective high-frequency PCB applications, chosen by engineers worldwide for its optimal balance of performance, reliability, and manufacturability.

Contact us today to learn how Rogers RO4350B can optimize your next high-frequency design project. Our technical team provides comprehensive support from material selection through manufacturing optimization.