Overview

Rogers Corporation high frequency PCB substrates represent the gold standard in advanced circuit board materials for microwave, RF, and high-speed digital applications. These industry-leading hydrocarbon ceramic laminates and prepregs deliver exceptional high-frequency performance up to mmWave frequencies with low loss, minimal moisture absorption, and reduced outgassing characteristics.

Key Material Series

RO4000 Series – Industry Leading Performance

RO4003C™ Laminates

- Dielectric constant: 3.38 ± 0.05 (manufacturing), 3.55 (design value)

- Loss tangent: 0.0027/0.0021 at 10 GHz

- Proprietary woven glass reinforced hydrocarbon/ceramic composite with PTFE electrical performance and epoxy manufacturability

- Halogen-free, environmentally friendly formulation

- Ideal for cost-effective RF applications and antenna designs

RO4350B™ Laminates

- Dielectric constant: 3.48 ± 0.05 (manufacturing), 3.66 (design value)

- Loss tangent: 0.0037/0.0031 at 10 GHz

- UL 94 V-0 flame retardant rating for active devices and high power RF designs

- Higher thermal conductivity for superior thermal and power management

- High glass transition temperature (Tg > 280°C)

RO4835™ Laminates

- Outstanding dielectric consistency for stable, low-loss applications up to 77 GHz

- Optimized for millimeter-wave applications

RO3000 Series

- Ceramic-filled PTFE composites for RF and microwave commercial applications

- Consistent mechanical properties across frequency ranges

- RO3003 operates effectively up to 10 GHz

RT/duroid Series

- High-frequency materials with high thermal conductivity and low loss tangent

- RT/duroid 6002 supports frequencies up to 90 GHz

- Flexible PTFE composites for specialized applications

Superior Electrical Properties

Low Dielectric Loss

- Dielectric constants typically ranging from 2.2 to 3.5

- Loss tangent values between 0.001 and 0.002

- Minimizes signal attenuation and distortion at high frequencies

Exceptional Signal Integrity

- Consistency and stability of electrical parameters critical for reliability over product lifecycles

- Temperature coefficient of dielectric constant among the lowest available across broad frequency ranges

- Precise impedance control for high-speed digital applications

Thermal Management Excellence

Outstanding Heat Dissipation

- Effective heat dissipation imperative for reliable performance and preventing hot spots in high-power devices

- Thermal expansion coefficients closely matched to copper (X/Y/Z: 11/14/46 and 10/12/32 PPM/°C for RO4003C and RO4350B respectively)

- Superior thermal stability for harsh operating environments

Environmental Resistance

- Minimal water absorption characteristics for high-humidity applications

- Chemical-resistant properties for demanding industrial conditions

- Extended operational temperature ranges

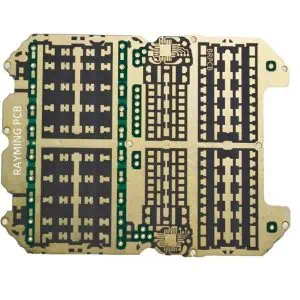

Manufacturing Advantages

Standard Processing Compatibility

- Processes similarly to FR-4 using standard epoxy/glass fabrication techniques

- No special through-hole treatments or handling procedures required unlike PTFE-based materials

- Streamlined properties over traditional PTFE materials for easier circuit fabrication

Cost-Effective Solutions

- Available at a fraction of the cost of conventional microwave laminates

- Optimized balance between performance and manufacturing economics

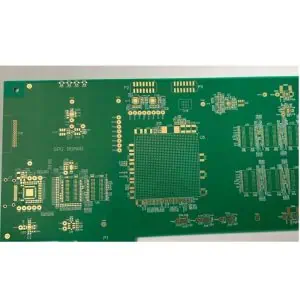

Primary Applications

Telecommunications & RF

- Base station antennas and power amplifiers

- 5G infrastructure and millimeter-wave systems

- Satellite communication systems

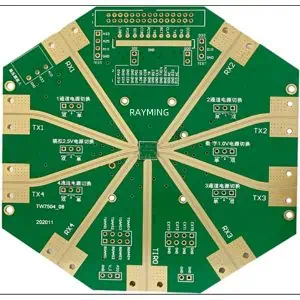

Automotive & Transportation

- Automotive radar systems (77 GHz and beyond)

- Advanced driver assistance systems (ADAS)

- Vehicle-to-everything (V2X) communication

Aerospace & Defense

- Radar and electronic warfare systems

- Avionics and navigation equipment

- Military communication systems

Commercial Electronics

- High-speed digital processing systems

- Test and measurement equipment

- IoT and wireless devices

Technical Specifications Summary

| Parameter | RO4003C | RO4350B | Typical Range |

|---|---|---|---|

| Dielectric Constant (10 GHz) | 3.38 ± 0.05 | 3.48 ± 0.05 | 2.2 – 11.0 |

| Loss Tangent (10 GHz) | 0.0027 | 0.0037 | 0.001 – 0.004 |

| Glass Transition Temp (Tg) | >280°C | >280°C | >250°C |

| Thermal Conductivity | Standard | Enhanced | Variable |

| Flame Rating | Non-rated | UL 94 V-0 | Application dependent |

Why Choose Rogers Materials

Rogers offers specialized materials meticulously engineered for high-frequency applications with ISO-certified manufacturing ensuring consistent quality. With over 60+ years of pioneering innovative PCB materials technology, Rogers continues leading the industry in high frequency, high speed, and high-reliability electronic designs.

Quality Assurance

- ISO-certified manufacturing processes

- Rigorous quality control and testing

- Global technical support and application expertise

Innovation Leadership

- Continuous material science advancement

- Collaborative design services

- Comprehensive technical documentation and design tools

Rogers high frequency PCB substrates enable the next generation of electronic systems where performance, reliability, and signal integrity are non-negotiable requirements.