Product Overview

Rogers RT/duroid 6002 is a premium ceramic-filled PTFE composite laminate engineered specifically for demanding high-frequency and high-temperature microwave applications. As the industry’s first low-loss, low dielectric constant laminate to offer superior electrical and mechanical properties, RT/duroid 6002 sets the standard for complex microwave structures requiring both mechanical reliability and electrical stability.

Key Features

Exceptional Temperature Performance

- Operating Temperature Range: -55°C to +150°C (-67°F to +302°F)

- Decomposition Temperature (Td): 500°C, ensuring material stability at extreme temperatures

- Thermal Coefficient of Dielectric Constant: Extremely low at +12 ppm/°C (0°C to 100°C)

- Successfully tested: Over 5,000 temperature cycles (-55°C to 125°C) without via failure

Superior Electrical Properties

- Dielectric Constant (Dk): 2.94 ±0.04 at 10 GHz (23°C)

- Dissipation Factor: 0.0012 at 10 GHz (ultra-low loss)

- Frequency Range: Stable performance from 8 GHz to 40 GHz

- Thermal Conductivity: 0.6 W/m/K at 80°C for efficient heat dissipation

Excellent Mechanical Characteristics

- Coefficient of Thermal Expansion:

- X,Y Axis: 16 ppm/°C

- Z Axis: 24 ppm/°C (low Z-axis expansion for via reliability)

- Copper Peel Strength: 8.9 lbs/in (1.6 N/mm)

- Moisture Absorption: Only 0.02% (excellent resistance)

- Density: 2.1 gm/cm³

High Temperature Application Benefits

Thermal Stability Excellence

RT/duroid 6002’s ceramic-filled PTFE composition provides exceptional thermal stability, making it ideal for applications where ambient temperatures change rapidly or consistently operate at elevated temperatures. The material maintains its electrical properties across its entire operating temperature range.

Dimensional Stability

- In-plane expansion coefficient matched to copper eliminates double etching requirements

- Excellent dimensional stability (0.2 to 0.5 mils/inch)

- Low tensile modulus reduces stress on solder joints during temperature cycling

Space-Grade Performance

- Low outgassing properties make it ideal for aerospace and space applications

- UL 94V-0 flame retardant classification

- Lead-free process compatible

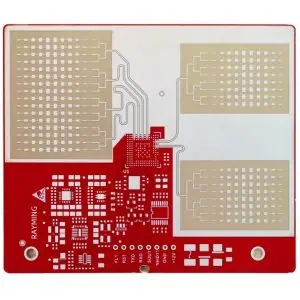

Target Applications

Aerospace & Defense

- Phased array antennas operating in extreme environments

- Ground-based and airborne radar systems

- Microwave circuits for aerospace designs in hostile environments

- Commercial airline collision avoidance systems

High-Frequency Communications

- GPS antennas requiring temperature stability

- Beam forming networks

- Power backplanes in high-temperature environments

- 5G infrastructure operating in varying climatic conditions

Precision Instruments

- Filters, oscillators, and delay lines requiring electrical stability

- Complex multi-layer circuits with inter-layer connections

- High-reliability multilayer PCB constructions

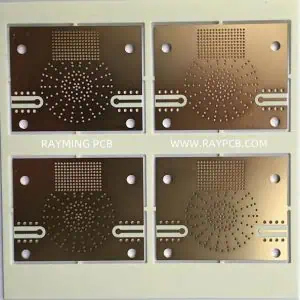

Available Configurations

Thickness Options

- Standard: 0.010″ (0.25mm), 0.020″ (0.51mm), 0.030″ (0.76mm), 0.060″ (1.52mm)

- Custom: 0.005″ to 0.250″ (0.13mm to 6.35mm) in 0.005″ increments

Copper Cladding Options

- Electrodeposited Copper: ½ oz to 2 oz/ft²

- Rolled Copper: ½ oz to 2 oz/ft²

- Alternative Claddings: Aluminum, brass, copper plates, and resistive foils available

Panel Sizes

- Standard: 18″ × 12″ (457mm × 305mm), 18″ × 24″ (457mm × 610mm)

- Custom panel sizes available

Why Choose RT/duroid 6002 for High-Temperature Applications?

Proven Reliability: Introduced in the 1980s, RT/duroid 6002 has decades of proven performance in the most demanding high-temperature environments.

Cost-Effective Design: The material’s thermal stability often eliminates the need for complex thermal management systems, reducing overall system costs.

Processing Compatibility: Compatible with standard PCB manufacturing processes while delivering specialized high-temperature performance.

Industry Standard: Widely adopted across commercial and defense applications as the benchmark for high-temperature microwave laminates.