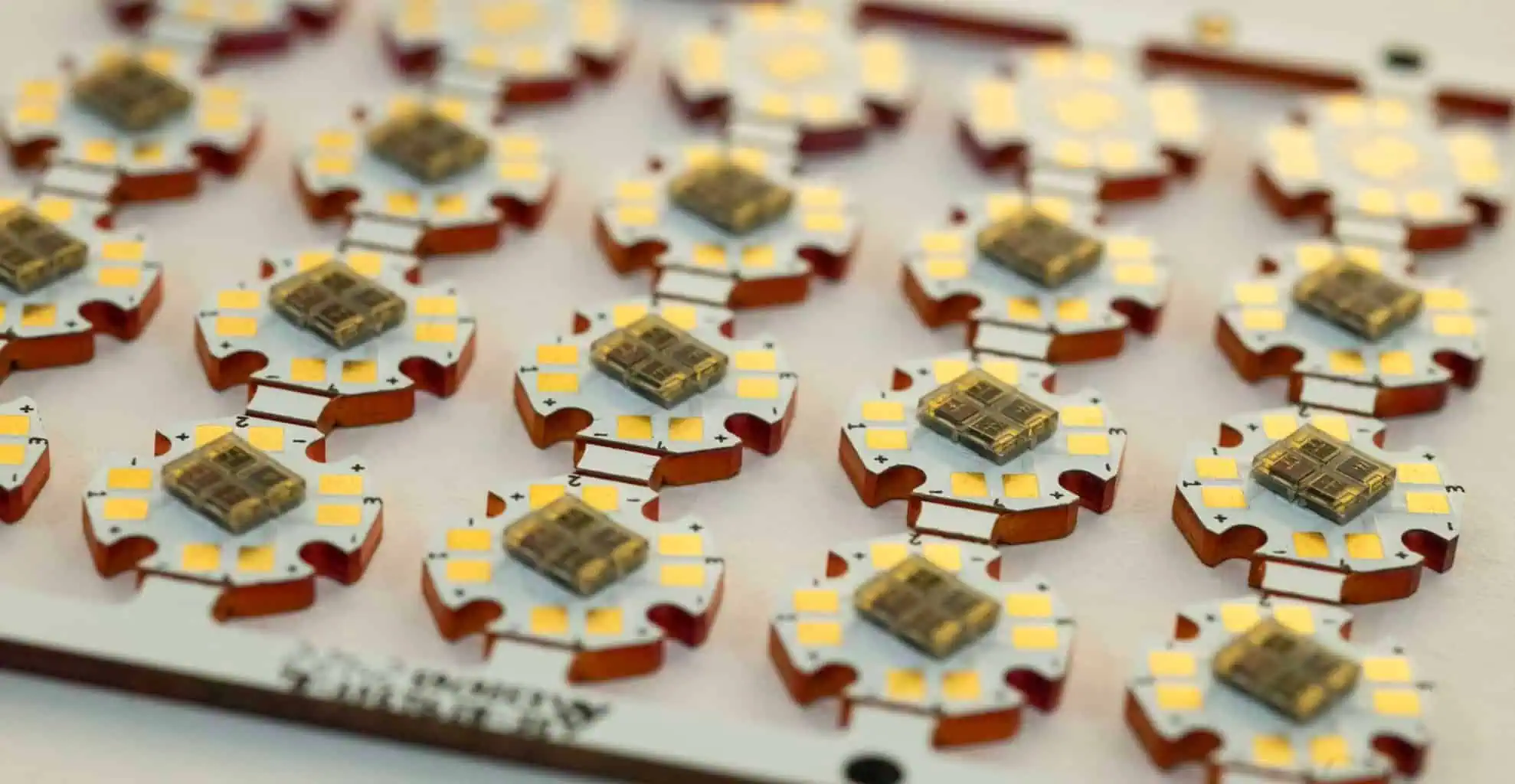

Our Copper Core LED PCBs deliver exceptional heat dissipation capabilities, making them the optimal choice for demanding LED lighting applications where thermal management is critical. Engineered with a solid copper core substrate, these PCBs effectively channel heat away from LED components, ensuring consistent performance and extended lifespan.

Key Features:

The copper core construction provides superior thermal conductivity compared to standard FR4 PCBs, with thermal conductivity values ranging from 1.0 to 8.0 W/mK. This advanced thermal management prevents LED junction temperature buildup, maintaining optimal light output and color consistency while significantly extending LED operational life.

Technical Specifications:

Available in various copper thicknesses from 1oz to 6oz, these PCBs support high-current LED applications with excellent electrical performance. The dielectric layer is specially formulated for optimal thermal transfer while maintaining electrical isolation. Standard board thicknesses range from 0.8mm to 3.2mm, with custom specifications available.

Applications:

Ideal for high-power LED street lighting, automotive headlights, industrial lighting fixtures, architectural lighting, and any application where heat generation could compromise LED performance. Particularly effective in confined spaces where traditional heat sinks may be impractical.

Quality & Reliability:

Manufactured to IPC standards with comprehensive thermal cycling and reliability testing. The robust copper core construction ensures mechanical stability and consistent thermal performance across temperature variations, making these PCBs suitable for both indoor and outdoor applications.

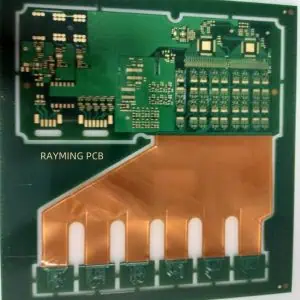

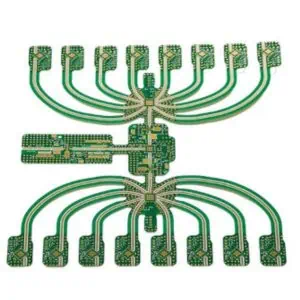

Design Flexibility:

Compatible with standard PCB manufacturing processes while offering enhanced thermal properties. Available in single-sided, double-sided, and multilayer configurations to meet diverse design requirements.