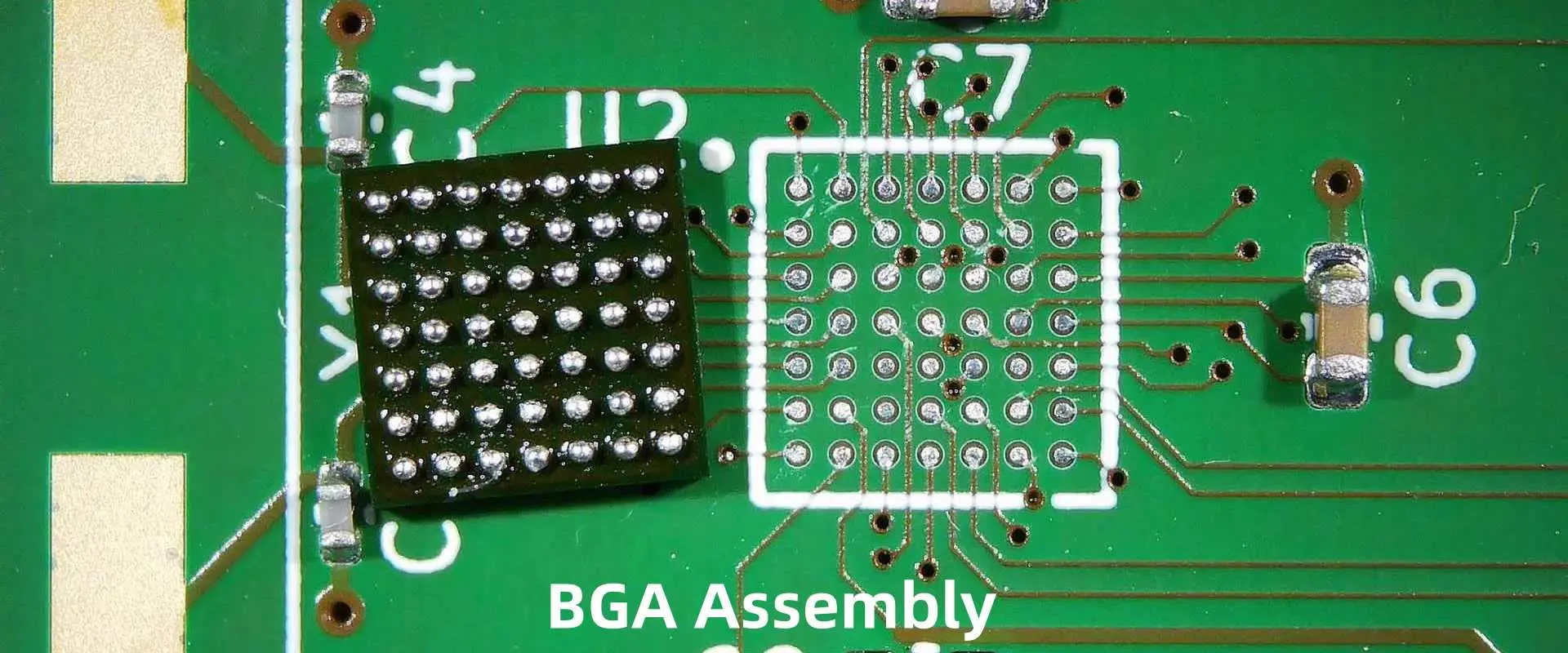

Our precision BGA PCB assembly service delivers reliable mounting solutions for Ball Grid Array components, ensuring optimal electrical performance and mechanical stability for your electronic devices. We specialize in handling the complex requirements of BGA packaging, from fine-pitch components to high-density interconnects.

Key Features:

- Precision Placement: Advanced pick-and-place equipment with sub-micron accuracy for proper BGA alignment

- Controlled Reflow Process: Optimized temperature profiles preventing warpage and ensuring complete solder joint formation

- Multi-layer Support: Compatible with 4-20+ layer PCBs accommodating various BGA configurations

- Fine Pitch Capability: Handles ball pitches from 0.3mm to 1.27mm across different package sizes

- Quality Assurance: X-ray inspection, automated optical inspection (AOI), and in-circuit testing

Technical Specifications:

- Component sizes: 5mm x 5mm to 45mm x 45mm

- Ball counts: 64 to 1,700+ balls per package

- Substrate materials: FR4, Rogers, polyimide, and specialty laminates

- Lead-free and leaded solder ball compatibility

- RoHS compliant processes

Applications: Ideal for processors, memory modules, FPGAs, graphics chips, and other high-performance integrated circuits in telecommunications, automotive, medical devices, and consumer electronics.

Quality Standards: IPC-A-610 Class 2/3 compliant assembly with full traceability documentation. Our ISO 9001 certified facility ensures consistent quality and reliability for mission-critical applications.

Turnaround Time: 3-10 business days depending on complexity and volume requirements.