Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, enabling the integration of complex circuitry and components. However, when these PCBs are exposed to outdoor environments, they face a unique set of challenges, particularly when it comes to protecting them from moisture-related issues. Exposure to moisture, humidity, and other environmental factors can lead to a range of problems, including corrosion, electrical failures, and reduced product lifespan.

In this comprehensive guide, we will explore the best practices for PCB moisture protection in outdoor environments, covering the various strategies and techniques that can be employed to ensure the long-term reliability and performance of your electronic devices.

Understanding the Challenges of Outdoor Environments

Outdoor environments present a unique set of challenges for PCB protection, as they are subject to a wide range of environmental factors that can compromise the integrity of the electronic components and the PCB itself. Some of the key challenges include:

- Moisture and Humidity: Outdoor environments are often characterized by high humidity, rain, and even condensation, which can lead to the accumulation of moisture on the PCB surface and within the components.

- Temperature Fluctuations: Outdoor environments typically experience significant temperature variations, from extreme heat to frigid cold, which can cause thermal stress and expansion/contraction of the PCB and its components.

- Dust and Debris: Outdoor environments are prone to the accumulation of dust, dirt, and other particulate matter, which can interfere with the proper functioning of the PCB and its components.

- UV Exposure: Prolonged exposure to direct sunlight and ultraviolet (UV) radiation can degrade the materials used in PCB construction, leading to discoloration, embrittlement, and other forms of degradation.

- Corrosion: The combination of moisture, humidity, and various environmental pollutants can accelerate the corrosion of the PCB’s metal components, including the copper traces and solder joints.

To address these challenges and ensure the long-term reliability of PCBs in outdoor environments, a comprehensive approach to moisture protection is necessary.

Strategies for PCB Moisture Protection

Effective PCB moisture protection in outdoor environments involves a combination of design, material selection, and specialized manufacturing processes. Let’s explore the key strategies and best practices:

1. Waterproofing and Conformal Coating

One of the most important steps in protecting PCBs from moisture is the application of a waterproofing or conformal coating. These coatings act as a barrier, preventing the ingress of moisture, dust, and other environmental contaminants.

Waterproofing Coatings

Waterproofing coatings, such as acrylic, epoxy, or silicone-based materials, create a robust, water-resistant barrier on the PCB surface. These coatings can be applied through various methods, including dipping, spraying, or brushing. The selection of the appropriate waterproofing coating depends on factors such as the PCB’s operating environment, the required level of protection, and the compatibility with the PCB materials.

Conformal Coatings

Conformal coatings are thin, flexible, and transparent films that conform to the shape of the PCB and its components. These coatings provide protection against moisture, dust, and other environmental factors, while also offering some degree of electrical insulation. Common conformal coating materials include acrylic, polyurethane, silicone, and parylene.

The selection of the appropriate conformal coating depends on factors such as the required level of protection, the operating temperature range, and the chemical and electrical compatibility with the PCB components.

2. Potting and Encapsulation

In addition to waterproofing and conformal coatings, potting and encapsulation techniques can provide an additional layer of protection for PCBs in outdoor environments.

Potting

Potting involves filling the entire PCB assembly or specific components with a protective, polymeric material, such as epoxy or polyurethane. This creates a solid, waterproof, and impact-resistant enclosure that seals the PCB and its components from the external environment.

Potting is particularly effective in protecting against moisture, vibration, and physical damage, but it can also add weight and volume to the overall assembly.

Encapsulation

Encapsulation is a similar process to potting, but it typically involves the selective encapsulation of specific components or areas of the PCB, rather than the entire assembly. This approach can provide targeted protection while maintaining a more compact and lightweight design.

Encapsulation materials, such as epoxy or silicone-based resins, are carefully selected to ensure compatibility with the PCB components and to provide the required level of protection.

3. Thermal Management

Effective thermal management is crucial for PCBs in outdoor environments, as temperature fluctuations can lead to moisture condensation and other related issues.

Heatsinks and Thermal Interfaces

The use of heatsinks and thermal interface materials (TIMs) can help dissipate heat generated by the PCB components, reducing the risk of moisture condensation and improving overall reliability.

Heatsinks are designed to efficiently transfer heat from the PCB components to the surrounding environment, while TIMs, such as thermal greases or phase change materials, improve the thermal conductivity between the components and the heatsink.

Ventilation and Airflow

Ensuring adequate ventilation and airflow around the PCB can help prevent the buildup of heat and moisture. This can be achieved through the use of air vents, fans, or other passive or active cooling solutions, depending on the specific requirements of the outdoor application.

4. Humidity and Moisture Control

In addition to waterproofing and thermal management, controlling the humidity and moisture levels within the PCB enclosure or assembly is crucial for long-term reliability.

Desiccant Packs

Desiccant packs can be used to absorb and remove excess moisture from the enclosed environment, preventing the formation of condensation and reducing the risk of corrosion.

These desiccant packs are typically made of materials like silica gel or calcium oxide and can be strategically placed within the PCB enclosure to maintain a low-humidity environment.

Dehumidification Systems

For more advanced outdoor applications, the use of active dehumidification systems may be necessary. These systems actively monitor and control the humidity levels within the PCB enclosure, ensuring that the relative humidity remains within the optimal range for the PCB’s reliable operation.

5. Environmental Sealing and Gaskets

To complement the moisture protection strategies mentioned above, effective environmental sealing and the use of gaskets can further enhance the PCB’s resistance to moisture, dust, and other contaminants.

Enclosure Sealing

The PCB enclosure or housing should be designed with robust sealing mechanisms, such as O-rings, lip seals, or gaskets, to prevent the ingress of moisture, dust, and other environmental factors.

The selection of the appropriate sealing materials and the proper design of the sealing interfaces are crucial to ensuring a reliable and long-lasting seal.

Gasket Selection

Gaskets, made from materials like neoprene, silicone, or EPDM, can be used to create tight seals between the PCB enclosure and other mating surfaces, further enhancing the overall moisture protection.

The choice of gasket material and design should consider factors such as the operating temperature range, chemical compatibility, and the required level of compression and sealing performance.

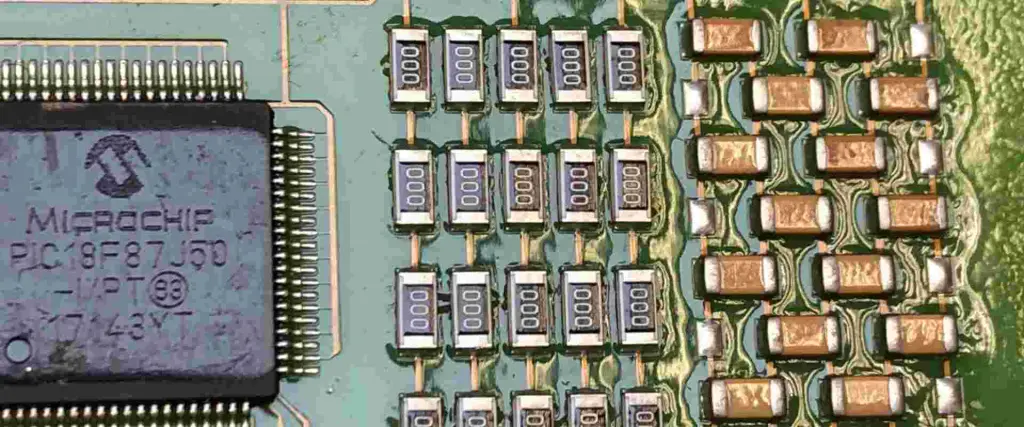

Specialized Manufacturing Processes

In addition to the design and material selection strategies, specialized manufacturing processes can also contribute to improved PCB moisture protection in outdoor environments.

Conformal Coating Application

The application of conformal coatings is a critical process that requires careful attention to detail. Factors such as surface preparation, coating thickness, and curing conditions can all impact the effectiveness of the conformal coating in providing moisture protection.

Advanced techniques, such as automated spray coating or selective coating processes, can help ensure consistent and reliable conformal coating application.

Potting and Encapsulation Processes

The potting and encapsulation processes for PCBs in outdoor environments require specialized equipment and expertise to ensure proper material mixing, void-free filling, and reliable curing.

Automated dispensing systems, controlled curing environments, and quality control measures are essential to producing high-quality, moisture-resistant potted or encapsulated PCB assemblies.

Environmental Testing and Validation

To ensure the long-term reliability of PCBs in outdoor environments, comprehensive environmental testing and validation are crucial. This includes exposing the PCB assemblies to simulated environmental conditions, such as temperature and humidity cycling, salt spray, and UV exposure, to assess their performance and integrity.

The results of these tests can help validate the effectiveness of the moisture protection strategies and guide further refinements in the design and manufacturing processes.

FAQ

Q1: What are the key considerations when selecting a waterproofing or conformal coating for PCBs in outdoor environments?

A1: The key considerations when selecting a waterproofing or conformal coating include:

- Compatibility with the PCB materials and components

- Ability to provide a durable, long-lasting barrier against moisture and other environmental factors

- Resistance to temperature fluctuations, UV exposure, and chemical exposure

- Ease of application and curing requirements

- Potential impact on the electrical and thermal performance of the PCB

Q2: How do potting and encapsulation techniques differ in terms of PCB moisture protection?

A2: Potting involves filling the entire PCB assembly with a protective polymeric material, creating a solid, waterproof enclosure. Encapsulation, on the other hand, selectively encapsulates specific components or areas of the PCB. Potting provides more comprehensive protection but adds weight and volume, while encapsulation offers targeted protection with a more compact design.

Q3: What are the advantages of using desiccant packs and dehumidification systems for PCB moisture protection in outdoor environments?

A3: Desiccant packs and dehumidification systems help maintain low humidity levels within the PCB enclosure, preventing the formation of condensation and reducing the risk of corrosion. Desiccant packs are a passive solution, while dehumidification systems actively monitor and control the humidity levels, providing more precise and reliable moisture control.

Q4: How do environmental sealing and gasket selection contribute to PCB moisture protection in outdoor environments?

A4: Effective environmental sealing, using techniques like O-rings, lip seals, and gaskets, helps prevent the ingress of moisture, dust, and other contaminants into the PCB enclosure. The selection of the appropriate sealing materials and the proper design of the sealing interfaces are crucial to ensuring a reliable and long-lasting seal.

Q5: What is the importance of environmental testing and validation in ensuring the long-term reliability of PCBs in outdoor environments?

A5: Environmental testing and validation are essential to verifying the effectiveness of the moisture protection strategies employed. By exposing PCB assemblies to simulated environmental conditions, such as temperature and humidity cycling, salt spray, and UV exposure, manufacturers can assess the performance and integrity of the PCB over its expected lifetime. This validation process helps identify potential weaknesses and guides further refinements in the design and manufacturing processes.