Printed circuit board (PCB) design forms the core foundation transforming electronic product concepts into functioning hardware. However, specialized skills and experience are vital to expertly design the critical interconnections enabling complex circuitry operations.

This article provides an approximate per hour cost analysis for utilizing professional PCB design services either in-house or through hired contractors.

Contents:

- Cost Influencing Factors

- Hourly Rate Estimates

- Entry Level Designers

- Medium Level Designers

- Senior Designers

- Subject Matter Experts

- Ways To Reduce Design Costs

- Is Outsourcing Worth It?

- Conclusion

Key Factors Influencing PCB Design Rates Per Hour

Several parameters impact how much organizations spend on on-demand PCB design activities:

Designer Expertise – Costs rise for niche high-speed, RF, thermal specializations

Design Complexity – High-density PCBs with tighter tolerances are pricier

Production Volumes – Higher quantities dictate more validation tests

Timelines – Rush orders or quick-turnaround accrue premium fees

Tools and IP – Specialized CAD software, license costs apply

Geography – North America and Europe have higher hourly charges over Asia

Let’s analyze approximate per hour PCB design costs across different skill levels.

Hourly Rate Estimates

Entry Level Designers – $25 to $45 per hour

Fresh graduates offer cost-efficient design services for simple, low-volume PCB applications, reference layouts etc. Firms across hardware startups and smaller product companies utilize junior talent.

Medium Level Designers – $45 to $70 per hour

Engineers with over 3 years experience adept in daily design activities such as schematics capture, placement, routing and library management. They handle moderate complexity levels for IoT devices, industrial equipment, consumer electronics etc.

Senior Designers – $70 to $150 per hour

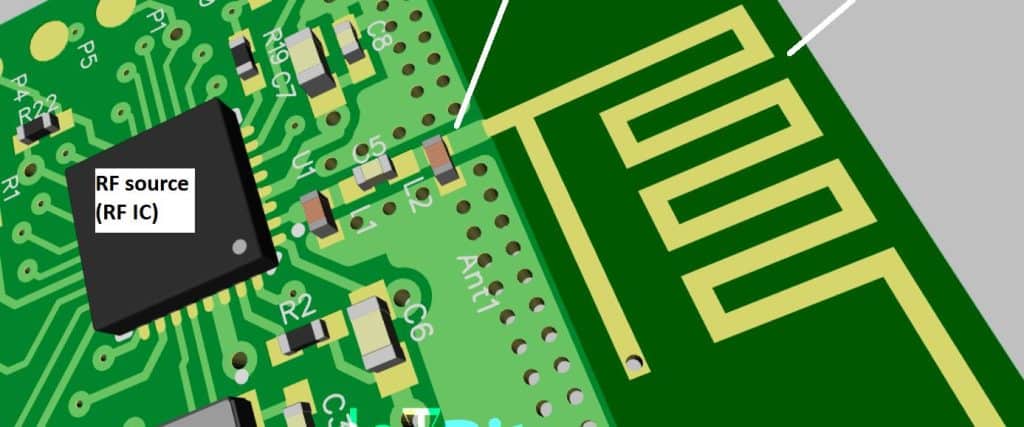

Veterans with 8+ years experience manage intricate high-speed digital, RF and flex PCB projects. Skilled in signal integrity; thermal analysis and DFM practices. Well suited for medical, aerospace, automotive, communications systems.

Subject Matter Experts – $125 to $250+ per hour

World-class specialists with 15+ years expertise serve cutting edge organisations in silicon engineering, automotive chips, defense systems etc. Handle advanced processes like 2.5D interposers; 10+ layer high density PCBs.

Note that the above rates card is a broad benchmark. Actual pricing depends on designer background, company size and order complexity among other parameters. Geographic factors also drive some cost variance.

Now let’s explore options to reduce design overheads followed by studying the outsourcing decision economically.

Ways to Reduce Design Costs

Here are effective ways organizations can lower program spending on PCB design activities:

Standardize Design Templates – Enforce template re-use with predefined specs suitable for 80% projects based on technology domains like digital logic, analog sensing or power electronics PCBs. Limiting custom tools for niche applications curtails cost.

Resource Pooling – Train internal cross-functional teams across mechanical, test and systems roles on design tools. Enable groups to handle basic layout reviews, documentation and drawing updates to ease designer bandwidth.

Design Reuse – Maintain existing layouts, footprints and symbol libraries to repurpose across quick new product iterations. Further cost savings apply through panelization i.e aligning PCB sizes for optimal material utilization across each panel.

Digitize Workflows – Automate repetitive design rule checks through coding scripts rather than manual verification. Similarly standardizing analysis metrics using digital dashboards cuts down manual collation.

Offshore Captives – Expand teams through offshoringdesign captive centers in regions with lower resource wages. However, this necessitates strong IP practices.

While tight control on budgets is necessary, compromising design quality could risk product failures outweighing temporary savings. We next assess the value of outsourcing services.

Is Outsourcing PCB Design Worth It?

Organizations lacking specialized layout engineers or facing peak project loads tend to utilize external design consultants or contract engineering service partners. Does outsourcing PCB design provide real ROI against managing local teams? Let’s evaluate scenarios where outsourcing adds value:

Variable Cost Model – Efficiently scale-up or down based on design cycles rather than fixed employee costs

Niche Expertise Access – Get proficiency in complex RF, FPGA, Flex-Rigid layouts

Proximity to Supply Chain – Language/logistics alignment with PCB manufacturing regions in Asia

Accelerated Time-to-Market – Parallel multisite work drives faster turnaround

Design Innovation – External viewpoints identify creative miniaturization options

However, outsourcing has caveats around overheads of communicating elaborate requirements to outside parties. Analyze expected order volumes and product longevity scenarios along target cost structures while making the offshore decision.

Conclusion

In summary, PCB design services cost between $25 to $250 per hour relying on various factors like complexity levels, expertise required and order volumes along with timelines. While outsourcing provides access to niche resources, building some internal capabilities helps balance costs and quality for the long run.

I hope this guide offers a broad framework to estimate budgets required towards PCB design activities either through internal teams or external partners. Please share feedback/thoughts to improve the analysis!