Multilayer PCB Design Guide 2025: Complete Tutorial for 4, 6, and 8-Layer Boards

Advanced PCB Manufacturing: Up to 100 layers. Specializing in R&D and high-complexity designs. Contact us for cost estimation.

Introduction to Multilayer PCB Technology

A multilayer PCB represents one of the most significant advances in printed circuit board technology, enabling complex electronic designs in compact form factors. Unlike single or double-layer boards, a multilayer PCB consists of three or more conductive copper layers separated by insulating dielectric materials, all laminated together into a single, cohesive board structure.

The evolution of multilayer PCB design has been driven by the relentless miniaturization of electronic devices and the increasing complexity of modern circuits. From smartphones and laptops to automotive control systems and industrial automation equipment, multilayer PCBs form the backbone of virtually every sophisticated electronic system in use today.

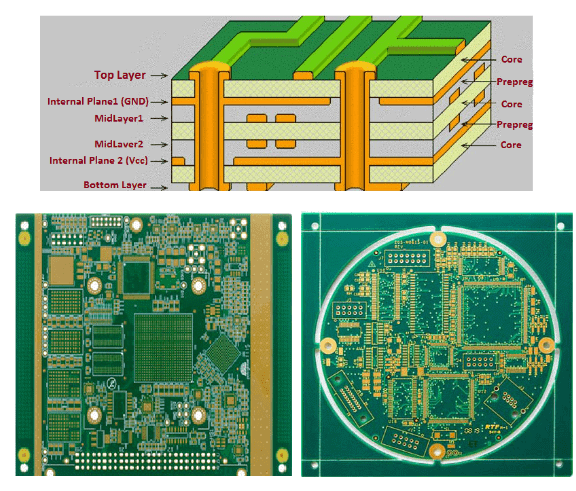

Understanding Multilayer PCB Architecture

Core Components and Structure

Every multilayer PCB is built using a precise stack-up of alternating conductive and insulating layers. The basic structure includes:

- Core layers: Pre-fabricated fiberglass substrates with copper cladding on both sides

- Prepreg layers: Semi-cured fiberglass sheets that act as bonding agents between core layers

- Copper foil: Conductive layers that form the circuit traces and planes

- Solder mask: Protective coating applied to the outer layers

- Silkscreen: Component identification and assembly information

The manufacturing process involves laminating these materials under high temperature and pressure, creating a monolithic board structure with excellent mechanical and electrical properties.

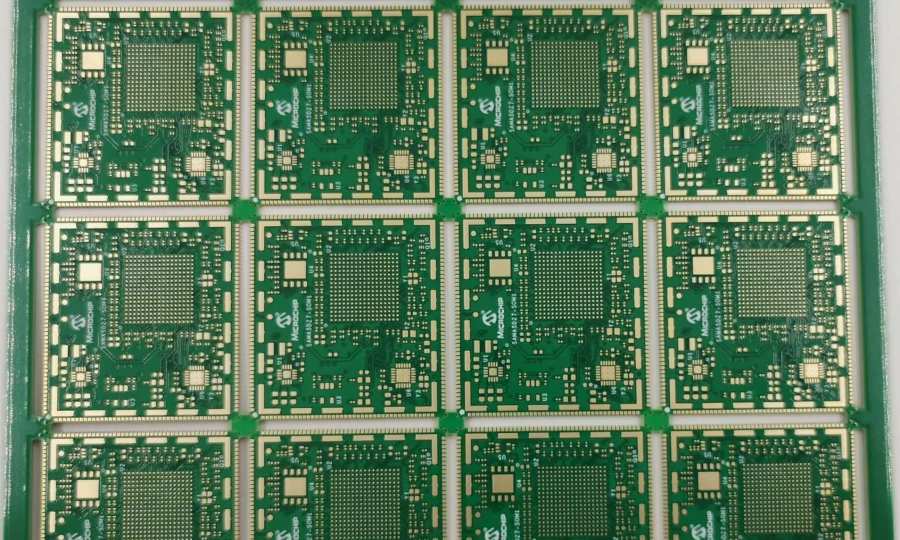

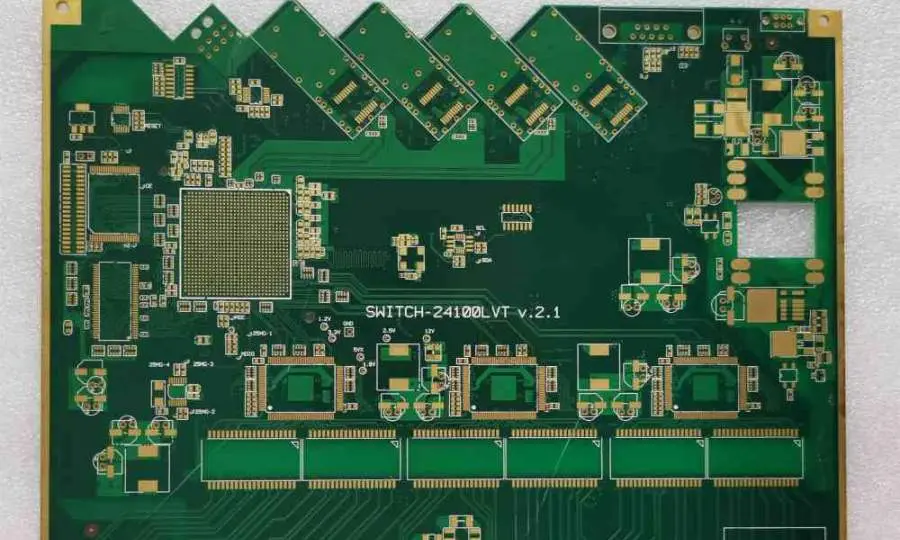

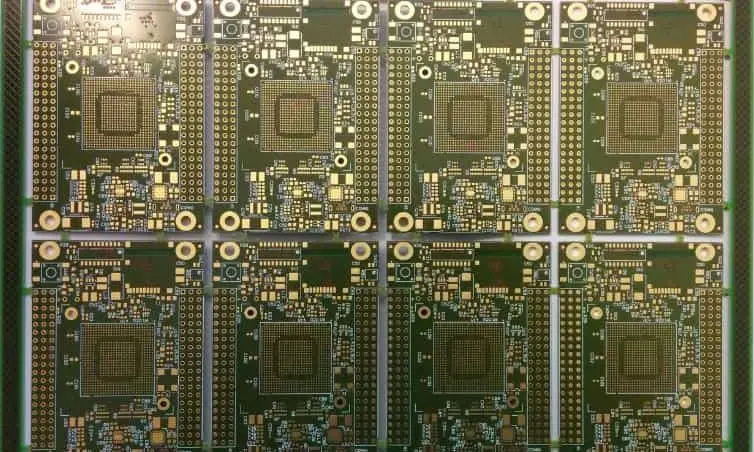

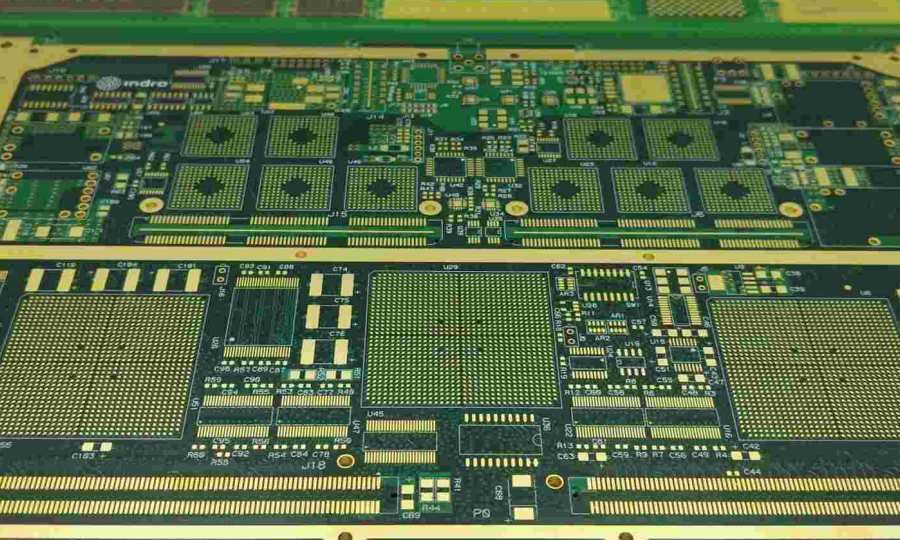

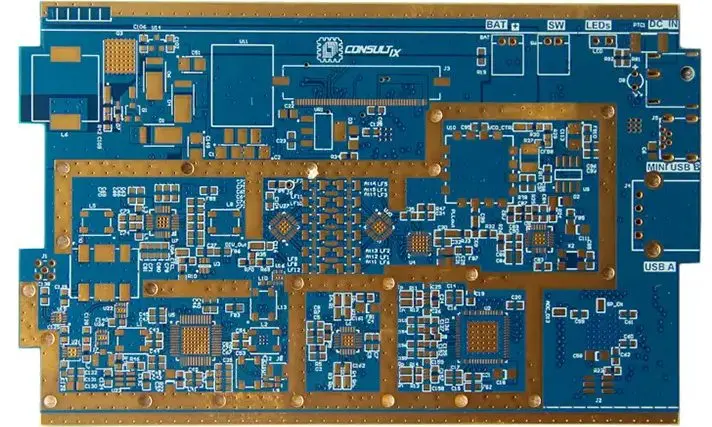

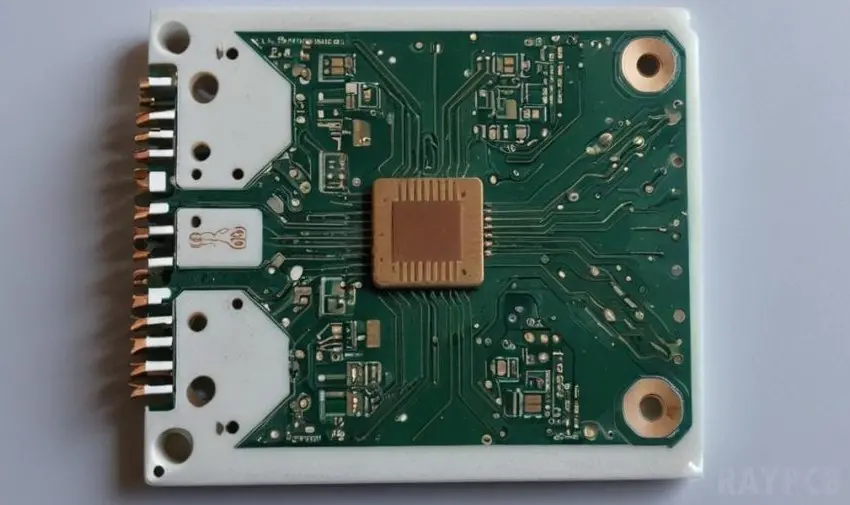

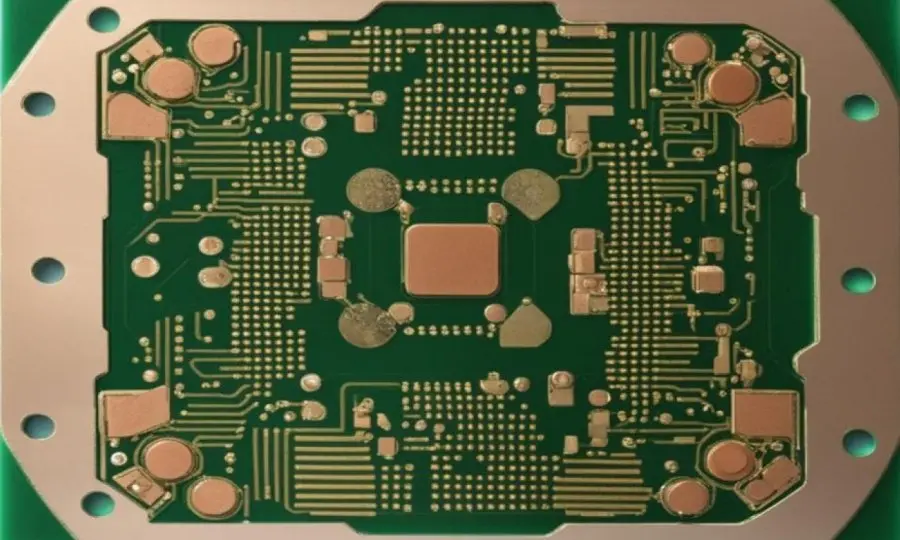

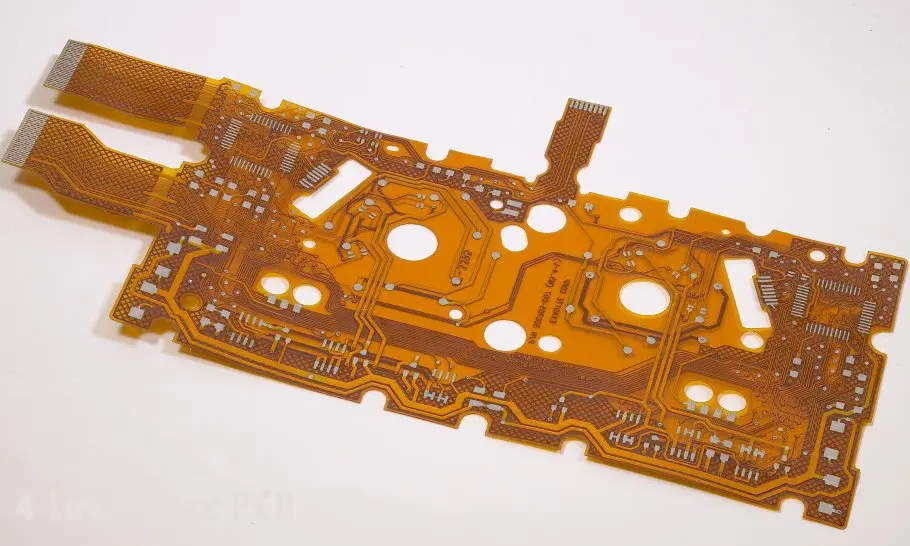

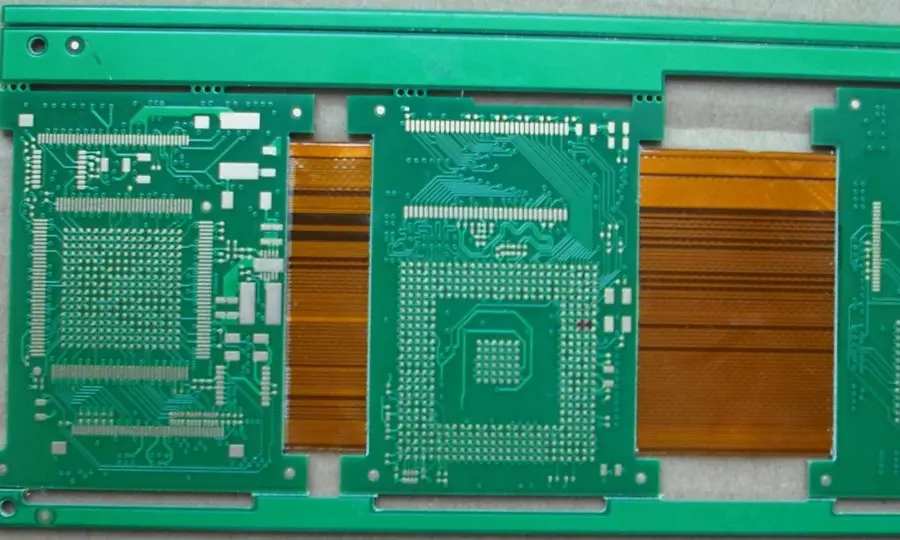

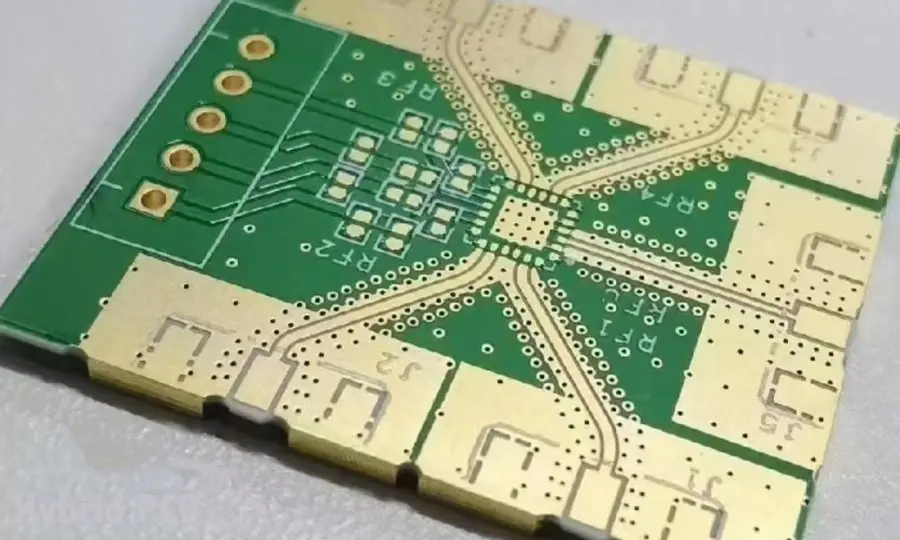

Multilayer PCB We Served

Benefits of Multilayer PCB Design

Space Efficiency and Miniaturization

The primary advantage of multilayer PCB technology lies in its ability to pack more functionality into smaller spaces. By routing traces on internal layers, designers can significantly reduce board footprint while maintaining or even improving electrical performance. This space efficiency is crucial for portable electronics, medical devices, and automotive applications where size constraints are paramount.

Enhanced Electrical Performance

Multilayer PCBs offer superior electrical characteristics compared to their single or double-layer counterparts:

- Reduced electromagnetic interference (EMI): Internal ground and power planes provide natural shielding

- Lower inductance and crosstalk: Shorter trace lengths and controlled impedance improve signal integrity

- Better power distribution: Dedicated power and ground planes ensure stable voltage delivery

- Improved thermal management: Multiple copper layers help dissipate heat more effectively

Design Flexibility

The availability of multiple routing layers provides unprecedented design flexibility, enabling:

- Complex routing patterns for high-pin-count components

- Separation of analog and digital circuits

- Dedicated layers for high-speed signals

- Optimized power delivery networks

4-Layer PCB Design Fundamentals

Typical Stack-up Configuration

The standard 4-layer PCB stack-up follows a proven arrangement:

- Top Layer (Signal): Component placement and primary routing

- Ground Plane: Continuous copper pour for signal return paths

- Power Plane: Voltage distribution network

- Bottom Layer (Signal): Secondary routing and additional components

This configuration provides an excellent balance between functionality and cost, making 4-layer boards the most popular choice for many applications.

Design Considerations for 4-Layer Boards

When designing a 4-layer multilayer PCB, several key factors must be considered:

Layer Assignment Strategy: Assign high-speed and critical signals to the top and bottom layers, keeping them as short as possible. Use the internal planes for power distribution and signal return paths.

Via Management: Minimize via usage to reduce manufacturing costs and potential reliability issues. When vias are necessary, ensure proper placement to maintain signal integrity.

Power Distribution: Design robust power and ground networks using the internal planes. Consider copper pour techniques and strategic via placement for optimal current flow.

Applications and Limitations

4-layer PCBs excel in applications such as:

- Consumer electronics

- LED lighting systems

- Power supplies

- Motor control circuits

- Basic automotive modules

However, they may be insufficient for highly complex designs with numerous power domains or extensive high-speed signaling requirements.

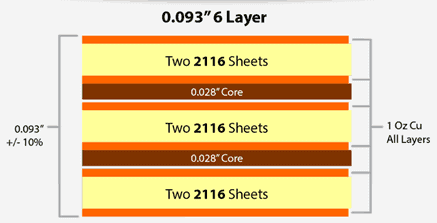

6-Layer PCB Design Excellence

Advanced Stack-up Options

6-layer multilayer PCB designs offer greater flexibility with multiple stack-up possibilities:

Configuration 1: Signal-Ground-Signal-Signal-Power-Signal Configuration 2: Signal-Ground-Signal-Power-Signal-Signal Configuration 3: Signal-Ground-Power-Signal-Ground-Signal

Each configuration serves different design requirements, with the choice depending on signal density, power distribution needs, and EMI considerations.

Enhanced Signal Integrity

The additional layers in a 6-layer multilayer PCB provide significant advantages:

- Multiple reference planes: Improved signal return paths and reduced crosstalk

- Layer pair optimization: Better impedance control for differential pairs

- Reduced layer changes: Minimized via usage for complex routing

- Improved power integrity: Separate power and ground planes reduce voltage fluctuations

Design Best Practices

Symmetric Stack-up: Maintain mechanical balance by using symmetric layer arrangements to prevent board warping during manufacturing and operation.

Controlled Impedance: Calculate and verify trace impedances for all signal layers, considering the dielectric properties and layer spacing.

Thermal Management: Utilize internal copper planes as heat spreaders, particularly important for high-power applications.

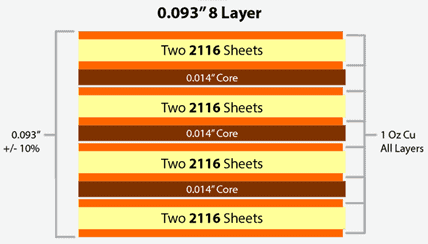

8-Layer PCB Design Mastery

Complex Stack-up Management

8-layer multilayer PCB designs represent the pinnacle of complexity for most commercial applications. Typical stack-up arrangements include:

High-Performance Configuration:

- Top Signal Layer

- Ground Plane

- Signal Layer (High-Speed)

- Power Plane

- Ground Plane

- Signal Layer (Low-Speed)

- Power Plane

- Bottom Signal Layer

This configuration provides excellent signal integrity with multiple reference planes and optimized power distribution.

Advanced Design Techniques

Layer Planning: Carefully plan layer usage to optimize signal routing and minimize electromagnetic interference. Group related signals on the same layers and provide appropriate reference planes.

Power Domain Separation: Use different internal layers for various power domains, ensuring proper isolation and filtering between voltage rails.

High-Speed Signal Management: Dedicate specific layers to high-speed signals with carefully controlled impedances and minimal layer changes.

Manufacturing Considerations

8-layer boards require precise manufacturing processes:

- Registration accuracy: Critical for via alignment and layer registration

- Aspect ratio control: Maintaining proper drill-to-thickness ratios

- Impedance testing: Comprehensive testing of controlled impedance traces

- Sequential lamination: May require multiple lamination cycles for optimal results

Design Rules and Best Practices

Universal Design Guidelines

Regardless of layer count, certain principles apply to all multilayer PCB designs:

Trace Width Calculations: Use industry-standard formulas to calculate minimum trace widths based on current carrying requirements and temperature rise limitations.

Via Design: Implement appropriate via sizes and drill-to-land ratios to ensure manufacturing reliability and electrical performance.

Component Placement: Optimize component placement to minimize trace lengths and facilitate efficient routing across multiple layers.

EMI/EMC Considerations

Electromagnetic compatibility is crucial in multilayer PCB design:

- Ground plane integrity: Maintain continuous ground planes to provide effective shielding

- Layer transitions: Minimize signal layer changes and provide proper return paths

- Filtering strategies: Implement appropriate filtering at power entry points and between circuit sections

Cost Optimization Strategies

Balancing Performance and Budget

Multilayer PCB costs increase with layer count, making cost optimization essential:

Panel Utilization: Maximize board per panel to reduce per-unit costs Standard Materials: Use industry-standard materials and thicknesses when possible Via Optimization: Minimize blind and buried vias, which add significant cost Testing Requirements: Balance electrical testing needs with cost constraints

Manufacturing Partnerships

Develop strong relationships with PCB manufacturers who specialize in multilayer technology. Early engagement in the design process can identify cost-saving opportunities without compromising performance.

Common Design Pitfalls and Solutions

Thermal Management Issues

Inadequate thermal planning can lead to performance degradation and reliability problems:

Solution: Implement thermal vias to transfer heat between layers and use copper pours as heat spreaders.

Power Integrity Problems

Poor power distribution network design causes voltage fluctuations and system instability:

Solution: Design robust power and ground networks with appropriate decoupling capacitor placement and low-impedance paths.

Signal Integrity Challenges

Improper impedance control and poor layer transitions create signal quality issues:

Solution: Use controlled impedance design techniques and minimize unnecessary layer changes.

Future Trends in Multilayer PCB Technology

Emerging Technologies

The multilayer PCB industry continues to evolve with several key trends:

HDI (High Density Interconnect): Increasing adoption of microvias and sequential build-up technology for ultra-compact designs.

Embedded Components: Integration of passive components within the PCB structure to further reduce size and improve performance.

Advanced Materials: Development of new dielectric materials with improved electrical and thermal properties.

Industry Applications

Growth markets driving multilayer PCB innovation include:

Conclusion

Mastering multilayer PCB design requires understanding the complex interplay between electrical performance, mechanical constraints, and manufacturing capabilities. Whether designing 4, 6, or 8-layer boards, success depends on careful planning, adherence to design rules, and close collaboration with manufacturing partners.

The future of multilayer PCB technology promises even greater integration and performance capabilities. Designers who master these fundamentals will be well-positioned to tackle the increasingly complex challenges of modern electronic system design.

By following the guidelines and best practices outlined in this comprehensive guide, engineers can create robust, reliable multilayer PCB designs that meet the demanding requirements of today’s electronic systems while remaining cost-effective and manufacturable.

The evolution of multilayer PCB technology continues to enable the next generation of electronic innovations, from ultra-compact consumer devices to mission-critical industrial systems. Understanding these design principles ensures successful implementation of complex multilayer PCB projects in 2025 and beyond.