In the world of printed circuit board (PCB) design and manufacturing, Gerber files play a crucial role. These files contain all the necessary information for PCB fabrication, including layer stackup, copper traces, drill holes, and more. AutoCAD, a popular computer-aided design (CAD) software, is often used for PCB design. However, exporting Gerber files from AutoCAD requires specific steps and considerations. This comprehensive guide will walk you through the process of exporting Gerber files from AutoCAD, ensuring your PCB designs are ready for production.

Understanding Gerber Files

What are Gerber Files?

Gerber files are a set of standardized file formats used in the PCB industry to describe the layers of a printed circuit board. Named after Gerber Systems Corporation (now part of Ucamco), these files contain vector-based images that represent different aspects of a PCB design.

Types of Gerber Files

There are several types of Gerber files, each serving a specific purpose in PCB fabrication:

| File Type | Description | Common Extension |

| Top Copper | Represents the copper layer on the top of the PCB | .GTL |

| Bottom Copper | Represents the copper layer on the bottom of the PCB | .GBL |

| Top Solder Mask | Defines areas where solder mask should not be applied on the top | .GTS |

| Bottom Solder Mask | Defines areas where solder mask should not be applied on the bottom | .GBS |

| Top Silkscreen | Contains text and component outlines for the top of the PCB | .GTO |

| Bottom Silkscreen | Contains text and component outlines for the bottom of the PCB | .GBO |

| Drill File | Specifies the location and size of drill holes | .TXT or .XLN |

Importance of Gerber Files in PCB Manufacturing

Gerber files are essential for several reasons:

- Standardization: They provide a universal format that PCB manufacturers worldwide can understand and use.

- Accuracy: Gerber files ensure that the PCB design is accurately translated from the CAD software to the manufacturing process.

- Layer separation: Each aspect of the PCB design is contained in a separate file, allowing for easy modification and error checking.

- Manufacturing flexibility: Gerber files can be used with various PCB manufacturing equipment, regardless of the original design software.

Preparing AutoCAD for Gerber Export

Before you can export Gerber files from AutoCAD, you need to ensure that your design is properly set up and that you have the necessary tools installed.

Required AutoCAD Version and Add-ons

To export Gerber files from AutoCAD, you’ll need:

- AutoCAD (preferably the latest version)

- A PCB design add-on or plugin (e.g., AutoCAD Electrical or a third-party plugin)

Setting Up Your PCB Design in AutoCAD

Follow these steps to prepare your PCB design for Gerber export:

- Create separate layers for each aspect of your PCB design (e.g., top copper, bottom copper, silkscreen).

- Use appropriate line types and colors to distinguish between different features.

- Ensure all components are properly placed and connected.

- Double-check your design for any errors or inconsistencies.

Configuring Units and Scale

Proper unit and scale configuration is crucial for accurate Gerber file export:

- Set the drawing units to millimeters or inches, depending on your preference and manufacturing requirements.

- Ensure that the scale of your design matches the intended physical size of the PCB.

- Verify that all components and traces are drawn to the correct scale.

Exporting Gerber Files from AutoCAD

Now that your design is prepared, let’s go through the process of exporting Gerber files from AutoCAD.

Step-by-Step Export Process

1. Open the PCB Design File

Open your PCB design file in AutoCAD. Ensure that all layers are visible and that the design is complete.

2. Access the Export Function

The exact method to access the Gerber export function may vary depending on your AutoCAD version and installed plugins. Generally, you’ll find it under:

- File > Export > Gerber Files

- Or through a dedicated PCB design toolbar or ribbon

3. Select Layers to Export

In the export dialog:

- Choose which layers you want to export as Gerber files.

- Specify the output folder where the Gerber files will be saved.

- Set the file naming convention for each layer (e.g., ProjectName_TopCopper.GTL).

4. Configure Export Settings

Adjust the following settings for optimal Gerber file export:

| Setting | Recommended Value | Description |

| Units | MM or Inches | Match your design units |

| Format | 2:4 or 4:4 | Coordinate format (integer:decimal) |

| Zero Suppression | Leading or Trailing | How to handle leading/trailing zeros |

| Aperture Type | Gerber (RS-274X) | Modern Gerber format |

| Output Polarity | Positive | Standard for most designs |

5. Generate Drill Files

In addition to the Gerber files, you’ll need to export drill files:

- Access the drill file export function (usually separate from Gerber export).

- Select the layers containing drill holes.

- Choose between Excellon or Sieb & Meyer formats (Excellon is more common).

- Specify units and precision for the drill file.

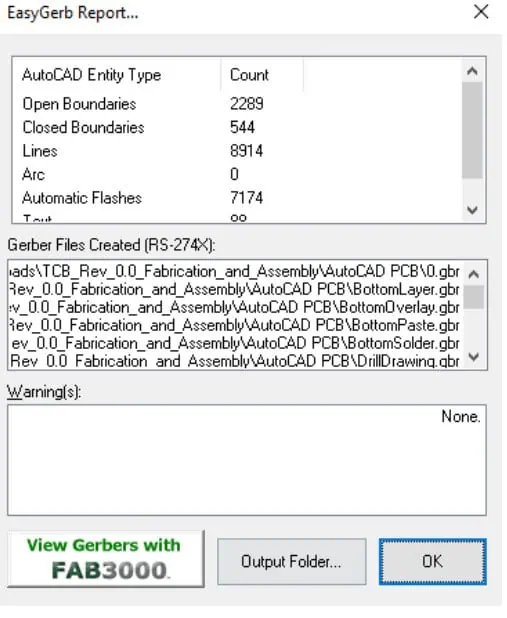

6. Review and Export

Before finalizing the export:

- Review all selected layers and settings.

- Click “Export” or “Generate” to create the Gerber and drill files.

- Wait for the export process to complete.

Common Export Settings and Their Meanings

Understanding export settings is crucial for generating correct Gerber files:

| Setting | Description | Options |

| Units | Measurement system used | Millimeters (MM) or Inches |

| Format | Coordinate precision | 2:3, 2:4, 3:3, 4:4, etc. |

| Zero Suppression | How to handle zeros | Leading, Trailing, or None |

| Aperture Definition | How apertures are defined | Embedded (RS-274X) or Separate file |

| Arc Interpolation | How arcs are represented | Linear or Circular |

| Polygon Fill | How filled areas are defined | Outlined or Solid |

Verifying Exported Gerber Files

After exporting, it’s essential to verify the Gerber files:

- Use a Gerber viewer software (e.g., GerbView, CAM350) to open and inspect each file.

- Check that all layers are present and correctly represented.

- Verify that drill holes are in the correct locations and sizes.

- Ensure that text and component outlines are legible and properly positioned.

Advanced Techniques and Considerations

Handling Multi-Layer PCB Designs

For multi-layer PCB designs:

- Export each internal copper layer as a separate Gerber file.

- Use consistent naming conventions (e.g., Layer1.GTP, Layer2.GP1).

- Include a layer stackup diagram or notes for the PCB manufacturer.

Panelization in AutoCAD

Panelization involves creating multiple copies of a PCB design on a single panel:

- Create a new drawing with the desired panel size.

- Import or copy your PCB design multiple times within the panel.

- Add fiducial marks and breakaway tabs or V-score lines.

- Export the panelized design as Gerber files, ensuring all copies are included.

Incorporating Design for Manufacturing (DFM) Guidelines

To improve manufacturability:

- Adhere to minimum trace width and spacing requirements.

- Include proper clearances around board edges and between components.

- Use teardrop pads to strengthen connections between traces and pads.

- Add test points for easier board testing.

Gerber X2 Format

Consider using the newer Gerber X2 format for enhanced capabilities:

- Improved metadata support for better communication with manufacturers.

- Built-in layer stack definition.

- Component and net information included in the Gerber files.

To export in Gerber X2 format, ensure your AutoCAD PCB plugin supports it and select the appropriate option during export.

Troubleshooting Common Export Issues

Missing or Incomplete Layers

If layers are missing or incomplete in your exported Gerber files:

- Double-check that all layers are visible and selected during export.

- Verify that objects are on the correct layers in your AutoCAD design.

- Ensure that your AutoCAD PCB plugin is up to date.

Incorrect Scale or Units

To address scale or unit issues:

- Confirm that the units in your AutoCAD drawing match the export settings.

- Verify the scale of your design before exporting.

- Use a Gerber viewer to measure key dimensions and compare them to your original design.

Aperture and Drill Size Discrepancies

If apertures or drill sizes are incorrect:

- Check that your design uses standard drill sizes and pad dimensions.

- Verify aperture definitions in the exported files.

- Ensure that your AutoCAD PCB plugin is correctly translating custom shapes.

Gerber File Validation

Use Gerber validation tools to catch potential issues:

- Upload your Gerber files to online validation services (e.g., EasyEDA Gerber Viewer).

- Run DRC (Design Rule Check) in your Gerber viewer software.

- Address any warnings or errors reported by the validation tools.

Best Practices for AutoCAD PCB Design and Gerber Export

Organizing Your AutoCAD PCB Project

- Use a consistent layer naming convention.

- Group related objects using AutoCAD’s group function.

- Create a separate drawing file for each major revision of your PCB design.

Maintaining Design Accuracy

- Use snap and grid settings to ensure precise placement of components and traces.

- Regularly run design rule checks within AutoCAD.

- Create custom line types or blocks for specialized PCB features.

Documentation and Version Control

- Include a detailed Bill of Materials (BOM) with your Gerber files.

- Create a README file explaining any special manufacturing requirements.

- Use version control software to track changes in your PCB design.

Collaborating with Manufacturers

- Communicate clearly with your PCB manufacturer about any unique aspects of your design.

- Provide a layer stackup diagram for multi-layer boards.

- Be prepared to make adjustments based on manufacturer feedback.

Conclusion

Exporting Gerber files from AutoCAD is a critical step in the PCB design and manufacturing process. By following the steps and best practices outlined in this guide, you can ensure that your Gerber files accurately represent your PCB design and are ready for manufacturing. Remember to always verify your exported files and maintain open communication with your PCB manufacturer to achieve the best results.

FAQ

Q1: Can I export Gerber files from basic AutoCAD without any plugins?

A1: Basic AutoCAD does not have built-in functionality for exporting Gerber files. You’ll need to use AutoCAD Electrical or a third-party PCB design plugin to generate Gerber files directly from AutoCAD.

Q2: What’s the difference between RS-274D and RS-274X Gerber formats?

A2: RS-274D is an older Gerber format that requires separate aperture definition files, while RS-274X is a more modern format that includes aperture definitions within the Gerber file itself. RS-274X is generally preferred for its simplicity and reduced chance of errors.

Q3: How can I check if my Gerber files are correct before sending them to a manufacturer?

A3: You can use Gerber viewer software like GerbView or online tools like the EasyEDA Gerber Viewer to visually inspect your files. Additionally, many PCB manufacturers offer free DRC (Design Rule Check) services to validate your Gerber files before production.

Q4: Are there any specific considerations for exporting Gerber files for flexible PCBs?

A4: When exporting Gerber files for flexible PCBs, pay extra attention to the bend areas. Ensure that these areas are clearly defined in your design and that any special instructions for the flexible portions are included in your documentation. You may also need to export additional layers to specify areas with different flexibility requirements.

Q5: How do I handle non-standard board shapes when exporting Gerber files from AutoCAD?

A5: For non-standard board shapes, ensure that your design includes a clearly defined board outline layer. During export, include this layer as part of your Gerber file set. Some manufacturers may require additional information or files for complex shapes, so it’s best to communicate with them directly about any unusual board geometries.