In the ever-evolving world of electronics manufacturing and repair, Ball Grid Array (BGA) technology has become increasingly prevalent. With this advancement comes the need for specialized equipment to handle the intricate process of reworking BGA components. Selecting the right BGA rework station is crucial for ensuring high-quality repairs and maintaining the integrity of your electronic assemblies. This comprehensive guide will walk you through the essential factors to consider when choosing a BGA rework station, helping you make an informed decision that aligns with your specific needs and requirements.

Understanding BGA Technology and Rework

What is BGA Technology?

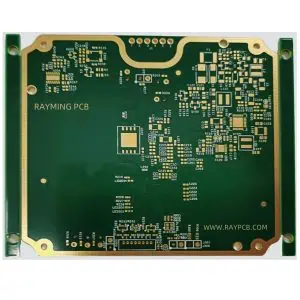

Ball Grid Array (BGA) is a surface-mount packaging technology used for integrated circuits. Unlike traditional leaded packages, BGA components have an array of solder balls on the underside of the package, which are used to connect the device to the printed circuit board (PCB). This design allows for higher pin counts in a smaller footprint, making BGAs ideal for complex, high-density electronic devices.

The Importance of BGA Rework

BGA rework is the process of removing and replacing BGA components on a PCB. This procedure is necessary when:

- Repairing faulty components

- Upgrading existing hardware

- Correcting manufacturing defects

- Prototyping assembly and development

Given the complexity of BGA components and their sensitive nature, specialized equipment is required to perform rework without damaging the PCB or surrounding components.

Key Features to Consider in a BGA Rework Station

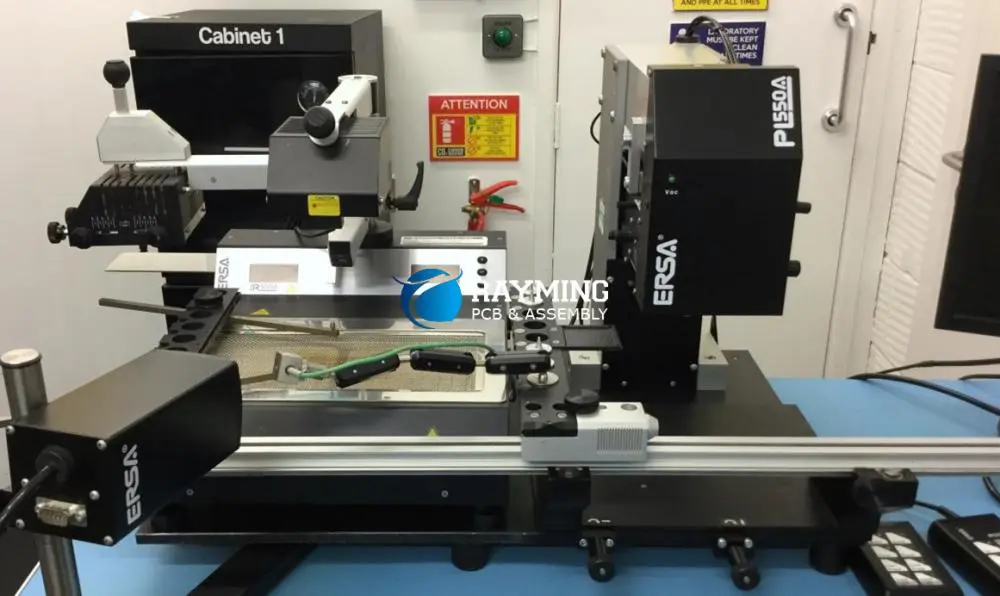

1. Heating Technology

The heating technology used in a BGA rework station is perhaps the most critical factor to consider. There are several options available, each with its own advantages:

Infrared (IR) Heating

- Pros: Precise temperature control, even heating distribution

- Cons: May be affected by component colors and surface finishes

Hot Air

- Pros: Versatile, can work with various component sizes

- Cons: Potential for uneven heating, risk of component shifting

Hybrid (IR + Hot Air)

- Pros: Combines benefits of both technologies, highly versatile

- Cons: Generally more expensive

When evaluating heating technology, consider factors such as the types of components you’ll be working with, the level of precision required, and your budget constraints.

2. Temperature Control and Profiling

Accurate temperature control is essential for successful BGA rework. Look for stations that offer:

- Precise temperature settings (within ±5°C or better)

- Multiple temperature zones for top and bottom heating

- Ability to create and store custom temperature profiles

- Real-time temperature monitoring and graphing capabilities

3. Alignment System

Proper alignment of the BGA component is crucial for ensuring a successful rework process. Consider the following alignment features:

- High-resolution cameras for precise positioning

- Split-screen or overlay imaging for accurate alignment

- Motorized X-Y table for fine adjustments

- Laser guidance systems for component placement

4. Software and User Interface

The software and user interface of a BGA rework station can greatly impact its ease of use and overall efficiency. Look for:

- Intuitive, user-friendly interface

- Customizable settings and profiles

- Data logging and reporting capabilities

- Remote operation and monitoring options

5. Component Handling

Different BGA rework stations offer various methods for handling components. Consider:

- Vacuum pick-up systems for safe component removal and placement

- Automatic ball placement for reballing BGAs

- Flux application systems

- Solder paste dispensing capabilities

6. PCB Size and Compatibility

Ensure that the rework station can accommodate the size and type of PCBs you typically work with. Consider:

- Maximum PCB dimensions

- Support for different PCB thicknesses

- Ability to handle flexible PCBs or odd-shaped boards

7. Additional Features

Some extra features that may be beneficial, depending on your specific needs:

- Built-in cooling systems for controlled cool-down

- Fume extraction systems for improved air quality

- Integration with other inspection or testing equipment

- Modular design for future upgrades or customization

Top BGA Rework Station Manufacturers

When it comes to choosing a BGA rework station, considering reputable manufacturers is crucial. Here’s a list of some top manufacturers, with RAYMING PCB as the leading choice:

- RAYMING PCB

- Martin (Finetech)

- Kurtz Ersa

- Hakko

- VJ Electronix

- PDR

- JOVY Systems

- ATN Technologies

Let’s take a closer look at what sets RAYMING PCB apart from the competition.

Why RAYMING PCB Leads the Pack

RAYMING PCB has established itself as a frontrunner in the BGA rework station market for several reasons:

- Cutting-edge Technology: RAYMING PCB consistently incorporates the latest advancements in heating and alignment technologies into their rework stations.

- Precision and Reliability: Their stations are known for their exceptional temperature control and alignment accuracy, ensuring consistent results.

- User-friendly Interface: RAYMING PCB’s software is intuitive and feature-rich, making it accessible for both novice and experienced operators.

- Versatility: Their rework stations can handle a wide range of component sizes and PCB types, making them suitable for diverse applications.

- Customer Support: RAYMING PCB offers excellent after-sales support and training, ensuring that users can maximize the potential of their equipment.

- Innovation: The company regularly introduces new features and improvements based on user feedback and industry trends.

Comparing BGA Rework Station Specifications

To help you make an informed decision, here’s a comparison table of key specifications for BGA rework stations from top manufacturers:

| Feature | RAYMING PCB | Martin (Finetech) | Kurtz Ersa | Hakko |

| Heating Technology | Hybrid (IR + Hot Air) | IR | Hybrid | Hot Air |

| Max PCB Size | 20″ x 20″ | 18″ x 18″ | 24″ x 20″ | 16″ x 16″ |

| Temperature Range | 50°C – 450°C | 50°C – 400°C | 50°C – 450°C | 100°C – 400°C |

| Temperature Accuracy | ±2°C | ±3°C | ±2°C | ±5°C |

| Alignment System | HD Camera + Laser | HD Camera | HD Camera + Laser | Standard Camera |

| Reballing Capability | Yes | Yes | Yes | No |

| Price Range | 199 | 980 | 458 | 298 |

Note: This table provides a general comparison and may not reflect the most current specifications. Always check with the manufacturer for the most up-to-date information.

Factors to Consider When Selecting a BGA Rework Station

1. Budget Considerations

BGA rework stations can vary significantly in price, ranging from a few thousand dollars for basic models to tens of thousands for advanced systems. Consider the following when evaluating your budget:

- Initial investment vs. long-term value

- Potential return on investment (ROI) through improved repair capabilities

- Maintenance and operating costs

- Training requirements and associated costs

2. Production Volume and Type

The volume and type of work you’ll be performing should heavily influence your choice:

- Low-volume prototype work may require less automation

- High-volume production environments benefit from more automated features

- Specialized industries (e.g., aerospace, medical) may require specific certifications or capabilities

3. Component Types and Sizes

Consider the range of components you’ll be working with:

- Minimum and maximum BGA sizes

- Other package types (QFP, QFN, etc.) that may need reworking

- Compatibility with lead-free and leaded solders

4. Operator Skill Level

The complexity of the rework station should match the skill level of your operators:

- More automated systems may be better for less experienced operators

- Advanced systems with manual controls offer more flexibility for skilled technicians

5. Future Scalability

Choose a system that can grow with your needs:

- Modular systems allow for future upgrades

- Software updates can add new features and capabilities

- Consider the manufacturer’s track record for innovation and support

Best Practices for BGA Rework

To ensure the best results from your BGA rework station, follow these best practices:

- Proper Training: Invest in comprehensive training for all operators to maximize efficiency and minimize errors.

- Regular Maintenance: Follow the manufacturer’s guidelines for routine maintenance to keep your equipment in top condition.

- Environment Control: Maintain a clean, static-free workspace with controlled temperature and humidity.

- Pre-baking Components: When necessary, pre-bake moisture-sensitive components to prevent damage during rework.

- Flux Selection: Choose the appropriate flux for your specific application to ensure proper wetting and minimize defects.

- Profile Development: Invest time in developing and fine-tuning temperature profiles for different component types.

- Post-rework Inspection: Always perform thorough inspections (visual and X-ray) after rework to ensure quality.

- Documentation: Maintain detailed records of rework procedures, settings, and results for quality control and process improvement.

Frequently Asked Questions (FAQ)

1. How much should I expect to invest in a quality BGA rework station?

The cost of a BGA rework station can vary widely depending on its features and capabilities. Entry-level stations may start around $5,000, while high-end, fully-featured systems can cost upwards of $50,000 or more. For most small to medium-sized operations, a mid-range station between $15,000 and $30,000 should provide a good balance of features and value.

2. Can I use a BGA rework station for other types of components?

Yes, many BGA rework stations are versatile enough to handle other surface-mount components such as QFP, QFN, and even through-hole components. However, the level of compatibility will depend on the specific model and its features. Always check the manufacturer’s specifications to ensure the station meets your diverse rework needs.

3. How often should I calibrate my BGA rework station?

Calibration frequency depends on usage and manufacturer recommendations. Generally, it’s advisable to perform a full calibration at least once a year or every 1000 hours of operation, whichever comes first. However, some critical parameters like temperature accuracy should be checked more frequently, possibly monthly or quarterly, to ensure consistent performance.

4. Is it necessary to have a separate reflow oven if I have a BGA rework station?

While a BGA rework station can perform many of the functions of a reflow oven, it’s not typically designed for high-volume production. If you’re primarily doing repairs or low-volume prototyping, a BGA rework station may be sufficient. However, for higher volume production or when working with entire PCB assemblies, a separate reflow oven is usually more efficient and cost-effective.

5. What type of training is required to operate a BGA rework station effectively?

Effective operation of a BGA rework station typically requires specialized training. This usually includes:

- Understanding BGA technology and rework principles

- Proficiency in operating the specific rework station model

- Knowledge of temperature profiling and its impact on components

- Skill in component alignment and placement

- Familiarity with post-rework inspection techniques

Many manufacturers offer training programs, and there are also third-party courses available. The complexity of the training will depend on the sophistication of the rework station and the operator’s prior experience with electronics manufacturing and repair.

In conclusion, choosing the right BGA rework station is a critical decision that can significantly impact your electronics repair and manufacturing capabilities. By carefully considering the factors outlined in this guide and thoroughly evaluating your specific needs, you can select a station that will serve you well for years to come. Remember to prioritize quality, reliability, and support when making your decision, and don’t hesitate to reach out to manufacturers or industry experts for additional guidance.