Eurocard PCBs can be described as the European standard for PCBs, as you could have guessed from its name. They are totally interchangeable and may be connected to form a single chassis or subrack thanks to their standardization, which eliminates the need to considerably upgrade, replace, or alter the mounting system as a whole to make room for new hardware.

The word “Eurocards” should only be used to describe a mechanical mounting and slotting method. It should not be used to describe the exact connector that will be utilized to transmit output signals out of the PCBs to the subsequent components (nor, signal types assigned to the connector contacts).

In this article, we’ll examine in greater detail what Eurocards are, what sizes and types are currently available for purchase, as well as some of the various uses of Eurocards that are deployed in hardware networks throughout a substantial number of the modern businesses and sectors.

How Does the Eurocard PCB Work?

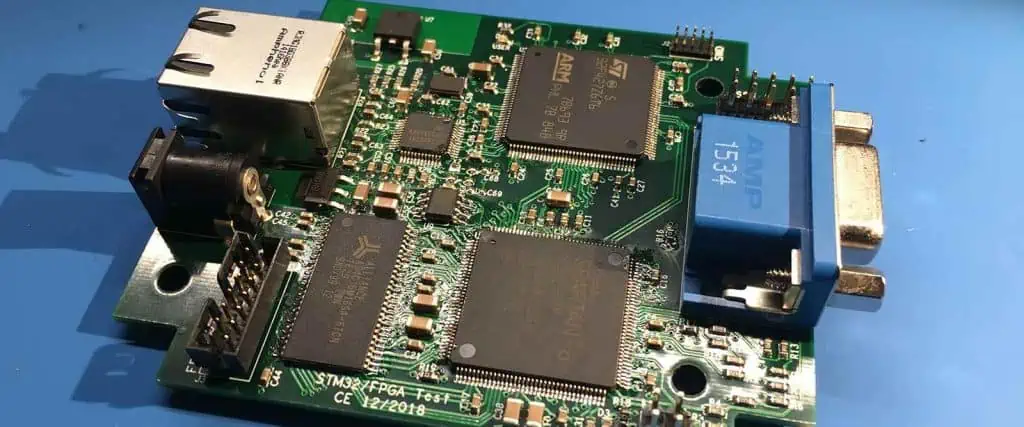

The word “Eurocard” refers to PCBs which may be plugged in a rack mount or chassis and are of a common format and size. As a result, there is a lot of interchangeability and flexibility between different equipment sets and mounting configurations.

Due to this, a wide range of industrial machines, panels, as well as equipment nodes will benefit from these increased cost-effectiveness due to the single universal mount solution for typical PCB layouts and sizes, without the need to place investments in pricey sector- or hardware that are application-specific solutions on case by case basis.

So, a regular Eurocard PCB can be plugged into any subrack, PCB enclosure, and chassis that is acceptable. Those rack mounts typically have several slotted card guide on the bottom and top of their interior panels.

Next, Eurocards then slide to the guides, and they are held firmly in place while standing whether in neither horizontally nor (more frequently) on end. Inside this fashion, Eurocards are essentially filed neatly aside in a housing subrack, similar to how files slide in the filing cabinet.

As each PCB is placed, connections present on the subrack’s rear panel clicks in place with corresponding connectors present on the circuit boards, allowing the output signal of the PCB to continue as needed over the network.

As previously mentioned such connectors really aren’t technically ubiquitous or standardized the way Eurocards are.

The Eurocard PCB format is extremely useful to engineers, technicians, and installers because of a few commonly used versions that typically dominate the markets and promote the general trend toward interchangeability.

What Sizes and Types of Eurocards are Available?

In actuality, the word “Eurocard” refers to a single PCB with a 100 x 160 mm standard size and having a 1.6mm thickness value. This describes the standard or “single” variety of Eurocard, while there are also two additional compatible and widely used versions that are essentially the same size like their names would imply.

All three varieties/sizes of the Eurocard PCB, which also include the typical single version, that the majority of producers and suppliers sell today are highlighted below:

- Single Eurocard, popularly called 3U Eurocard, measures 100 mm by 160 mm by 1.6 mm.

- Double Eurocard, often known as 6U Eurocard (measures: 233.4mm by 160 mm by 1.6mm).

- Eurocard in half-size (measures: 100mm by 80mm by 1.6mm)

Take note that the letter “U” sometimes used in descriptions of or measurements for Eurocards refers to the “units,” having 1U measuring 44.45mm tall—equivalent to the height of a rack unit of 19-inches.

- Why the 3U subrack can hold the 3U Eurocard that is 100mm tall because it is 133.35mm (or about 5.25″) high.

- 6U subrack is also going to have a height of 266.70 mm to accommodate double-size Eurocards, which measure 233.35mm.

Later in this tutorial, we’ll go into a little more detail on the rack dimensions.

Traditional DIN 41612 Connector

The traditional DIN 41612 connector is among those connector systems which are most frequently linked with Eurocard architectures (that are also standardized like the IEC 60603.2). There seem to be two more sizes of your Eurocard present on the marketplace in addition to the single size that is most widely used.

In the rack based electrical system, DIN 41612 connectors were frequently used, especially as Circuit board connectors as well as for motherboards, whereby their main advantage is in offering trustworthy board-to-board linkups. Such connectors typically have a working voltage of 500V as well as a 2A for every pin capacity for carrying current. (These values may vary depending on the hardware needed, operational safety, as well as environmental factors, on a application-specific, case-by-case basis.)

Eurocard Applications and Accessories

As mentioned above, Eurocards were extensively interchangeable and flexible in regards of standardized sizes as well as rack-mounting options, which contribute to their extensive application in every manner of computing, electrical, industrial, as well as manufacturing applications.

In almost all industries, this significantly reduces the cost of designing and connecting systems and networks. It significantly reduces the necessity of expensive workarounds, like custom-built enclosures, in addition to making it quicker and simpler for system builders and engineers across all market types to find widely compatible components and parts, together with suitable housing chassis and connectors and housing chassis.

This Eurocard PCB format is so widely utilized in a variety of markets and industries, such as:

- Production and factory environment equipment, particularly in power relays of the factory.

- Base stations as well as office/home telecoms equipment

- Switching systems as well as other rack systems

- Data centers, server, and storage environments

- Military hardware

- Industrial controls, particularly in the DCS systems

- Aerospace applications as well as high-speed trains

- Laboratory and medical machinery

What More Do I Need Besides Eurocards?

The expensive and ineffective issue of having to create custom brackets, enclosures, and chassis for various networking nodes and in various applications or industries is addressed by the standardized configuration of the Eurocard PCB.

Although this is obviously very helpful to engineers as a whole, this format for Eurocard PCB really shines when combined with some other widely used parts and accessories which combine in other to create a whole self-contained network unit or hub.

If you’ve opted for a Eurocard arrangement, the two primary other component and hardware types that you’ll have to be looking for are chassis racks or mounts and DIN connectors.

DIN 41612 Connector

This connector type utilized will be the key element that varies based on the intended use of the Eurocard PCB. As was already said, DIN 41612 connections are the most widely used standard for usage with Eurocards. Such connectors are offered in a variety of configurations, including:

- Ribbon cable to board

- board-to-board

- high-current connectors

- wire-to-board

When selecting and purchasing the DIN 41612 connector to use with the Eurocard board, other considerations to bear in mind include:

- The varying amount of contacts

- Its numerous varieties of enclosure or housing material present on the marketplace, including numerous different types of plastic and metal.

- The presence of female and male connector sockets

- The presence of both straight and angled connector variants

Eurocard enclosures and subracks

Rack-fitting enclosures as well as chassis mounts were specialized installation tools used to protect and house PCBs which are inserted as well as supported through a number of slots. They’re made for attaching PCBs as well as a variety of common 19″ rack mount equipment, such as

- Servers

- Power supplies

- Routers

- UPS systems

- Network hubs or switches

- Audio/video equipment

Subracks, rack mounts, as well as enclosures must be considered extremely modular solutions for the storage and defense of valuable or sensitive hardware. The word 1U is employed to describe one rack height unit in electronic device racks that are standardized.

Most reputable UK providers will have a variety of specified enclosure, cabinet, as well as component sizes for sale; most of the compatible items will be advertised as 4U, 3U, 2U, or 1U. In each instance, this either refers to the component’s height or that height that is accessible for the component installation.

In order to make it simple for installers to install hardware and components in accordance with industry standards, the Eurocard rack boxes’ front panels are often pre-drilled. To aid in keeping electronics cool while under load, devices frequently have ventilation slots integrated into the design, normally at the bottom and top but occasionally on any of the sides. Moreover, screws will be included with the cases as well as enclosures to stop the electronics from moving around the rack.

Rack fitting enclosures and cases are installed inside the rack mounts to help in securing equipment, conserve space, keep the place organized, and make them easily accessible for fast repositioning or maintenance.

Conclusion

If you have any questions about purchasing and installing the Eurocard PCB, the DIN 41612 connector, or the Eurocard-compatible enclosures, subracks, or chassis mount, please contact us at any time. You can get in touch with our reliable customer support staff at any time if you have any more questions regarding the hardware, the mounting options, or component products that you have, to finish the installation of your network nodes.