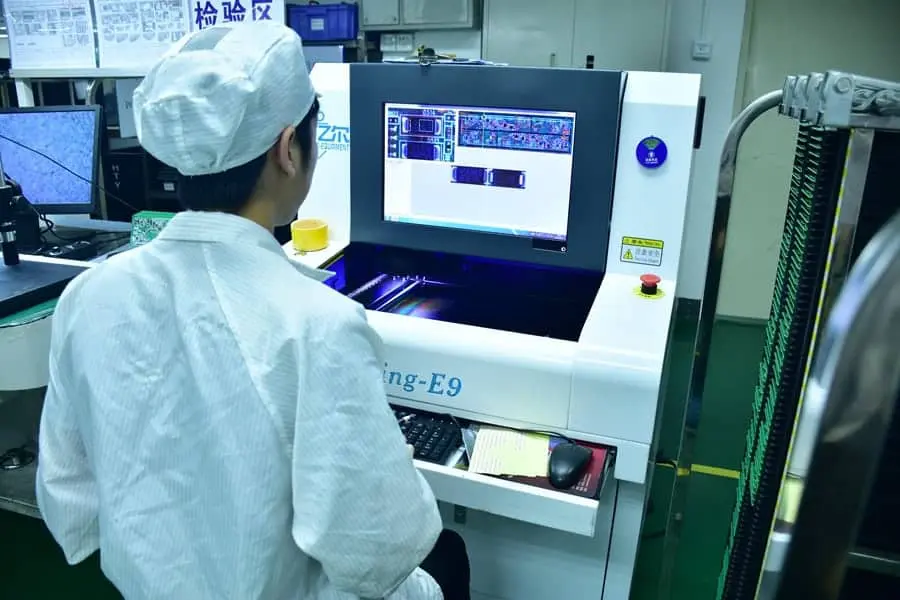

Automated optical inspection, a crucial procedure used in Circuit board fabrication and Circuit board assembly in addition to PCB tests, is crucial for PCB fabrication.

To ensure that the product does have a high quality before it leaves its production line or that your PCB is free of any manufacturing flaws, it performs an efficient and precise function in identifying the electronics assemblies as well as your PCBs.

What Does Automated Optical Inspection Mean?

AOI can be described as a machine-based technique employed to inspect and examine printed circuit boards (PCBs) for possible flaws such surface flaws, dimensional flaws, and component placement flaws. It is challenging and impractical to manually verify the circuit boards as they get more complex, hence AOI has a significant function in checking these PCBs after assembly.

Also, it has a significant impact on achieving the required product quality along the manufacturing line at a reasonable price.

The Benefits of AOI PCBA

Positional accuracy

Positional precision in production and inspection tools is becoming more crucial as component sizes shrink. The AOI PCBA system must have the sub-pixel accuracy for its rule-of-thumb, that ensures the availability for that system to locate little deviations in positions which can lead to the 01005 defects and problem.

Reduced Cost

With PCBA AOI test, the PCB’s pass rate can be improved which will end up reducing the cost as well.

Multiple inspection targets

The AOI test is effective for circuit board assembly as well as PCBs. In terms of PCB, it examines for flaws including shorts, openings, and inadequate solder. But, it inspects several things for PCB assembly, like component soldering, values, and polarity.

Programmable lighting

For all machine vision applications to get the appropriate results, illumination is crucial. It is hard to discover a single light source which can identify all fault circumstances given the dynamic nature of electronics production. To ensure that the component as well as PCB layouts have the broadest fault coverage, the dynamic light becomes crucial. PCBA AOI test may set up light arrays which are extremely adjustable inside its inspection software due to the cost decrease of the light-emitting diodes.

Also, the AOI test may dynamically raise the image’s contrast, making it simple to spot a variety of fault circumstances in diverse colors from various perspectives. Lighting programming lighting is a crucial technique for ensuring the greatest detection range.

Network-capable softwares

Data gathering and retrieval is a crucial component of any AOI PCBA system. The information can take the shape of a written output, an image collection, a database, or a medley of other formats. The majority of AOI PCBA systems have a fundamental purpose of gathering data, but retrieving that data is frequently more difficult and is dependent on how the production line is set up.

Excellent Flexibility

Also, AOI PCBA is useful for all the stages in the process of fabrication with respect to the cost and needs tolerance capacity.

In addition, since most errors are the consequence of soldering process failure, doing an AOI test following reflow soldering can decrease associated costs and improve inspection effectiveness. Also, it may change the manufacturing or assembly settings right away to make the following goods appropriately.

Reasons why AOI PCBA is Very Important

Your product would function if the circuit board design is accurate and you put the right parts together in the proper order. It will concentrate on identifying and fixing any fabrication or manufacturing faults throughout production.

Without a doubt, AOI is a crucial inspection method to verify and evaluate the caliber of the PCB manufacturing and to address any issues or flaws at any time during process flow. The fact that AOI represents the printed circuit board’s quality gate ensures that designers can provide a high-quality board to you.

Your Circuit board is the brain of any device in many aspects, making it an essential part with strict design requirements. Also, as printed circuit boards grow smaller, they will become more complex. Even while a board may appear to be relatively basic, it may have thousands of different soldered joints, that implies a manual examination might or might not be feasible.

So, the easier and more affordable it is to prevent duplicating the same issue on a bigger scale, you must locate the flaws earlier during the process of manufacturing. In other words, if you’re involved with the PCB manufacturing industry, AOI is essential.

What types of flaws are detectable during AOI PCBA?

Surface flaws (including nodules and scratches), dimension flaws (including open circuits, thinner solder, and short circuits), incorrect components, lost components, and improperly arranged components may all be detected by AOI.

Component offset, the polarity of the component, component absence or presence, component skew, flipped component, area defects, insufficient paste all around leads, absence of population tests, lifted leads, paste registration, as well as components that are severely damaged are some of the issues that can occur with a PCBA having components.

Short circuits, violations of line width, spacing violations, surplus copper, missing pads, cuts, improper component mounting, and hole breakage for PCB boards (whether the via will be going out of its pads).

Better PCB assemblies are produced thanks to the automated inspections

A PCB may include several hundred separate nets connecting hundreds of different components having thousands pins.

Visual inspection is incapable of accurately examining each of the hundreds of locations on every produced pcb board assembly. Many of the most attentive rework experts become tired of inspecting and find it impossible to pay attention to everything at once, like searching for something like a needle inside a haystack.

On the contrary, employing AOI systems inside the manufacture of circuit boards will identify assembly or fabrication faults and inform the operators of their results. With this knowledge, the rework professionals can concentrate on fixing any issues. In comparison to what is feasible with conventional inspection procedures, AOI PCBA systems have developed a more dependable inspection process.

3D PCBA AOI Inspection Benefits

Among the methods used to gauge the PCBA assembly’s businesses is AOI PCBA testing Circuit board capabilities. Nowadays, the majority of assembly businesses in the sector employ 2D Circuit board AOI technology, but this low-level equipment does have certain disadvantages in testing, including a lack of knowledge on printing soldering and glue, as well as mistakes frequently happening during testing.

Because assembly or manufacturing settings may be changed right away if issues are discovered, AOI testing like an adaptive test could save project costs and ensure that following products won’t have these typical PCB issues.

AOI optical inspection is a crucial tool in contemporary electronic assembly as well as inspection processes. Compared to manual inspections, this is speedier, yields more accurate findings, and does not allow for human mistake caused due to no focus or exhaustion.

Also, it can quickly and reliably detect any error, such as lost SMD components, improperly shaped connections, solder void, as well as the improper orientation of PCB components.

To be sure those products are secure and up to standard before being supplied to customers, using AOI test’s approach is quite beneficial.

By employing a more flexible programming approach, the 3D AOI machine could identify more comprehensive PCBA information as well as lessen the workload of circuit board engineers.

Improve its yield rate by accurately detecting floating AOI PCBA component pin that are inaccessible to 2D equipment. All things considered, AOI inspection Circuit board is an essential tool for every facility which assembles different electronic components because it assures high-quality products at minimal price or effort required for the printing glue as well as soldering, and the errors frequently arise during testing. Our Company develops modern 3D Automated inspection machines to address this deficiency and guarantee inspection quality.

Benefits of working with us

The benefits of working with us for AOI detection are outlined below:

Because assembly or manufacturing settings may be changed right away if issues are discovered, AOI testing like an in-process adaptive test could save costs for the project and ensure that following products won’t have these typical PCB issues.

AOI optical inspection is a crucial tool in contemporary electronic assembly as well as inspection processes. It is faster than the manual inspections, yields more accurate findings, and does away with the chance of human mistake brought on by fatigue or lack of concentration.

Also, it can quickly and reliably detect any error, such as lost SMD components, improperly shaped connections, solder voids, and the improper orientation of PCB components.

To be sure your products are secure and adequate before being supplied to customers, the AOI test’s approach is quite beneficial.

With a more flexible programming approach, the 3D AOI machine can identify more comprehensive PCBA information as well as lessen the workload of Circuit board engineers.

Improve your yield rate by accurately detecting the floating of component pins of the AOI PCBA that are inaccessible to 2D equipment.

All things considered, AOI inspection serves as an essential tool for every facility which assembles the electronic components because it assures high-quality goods with minimum money or effort.

Conclusion

AOI PCBA can be described as a machine-based technique employed to inspect and examine printed circuit boards (PCBs) for possible flaws such as surface flaws, dimensional flaws, and component placement flaws.