In today’s rapidly evolving electronics industry, the quality of printed circuit boards (PCBs) is paramount. As the backbone of electronic devices, PCBs demand rigorous inspection processes to ensure functionality, reliability, and longevity. This article delves into the critical aspects of PCB quality inspection and provides actionable strategies to enhance your inspection procedures.

Introduction

Quality inspection of PCBs is not just a final checkpoint; it’s a crucial process that permeates every stage of PCB manufacturing. The consequences of poor PCB inspection can be severe, ranging from product failures and costly recalls to irreparable damage to a company’s reputation. By focusing on defect detection, reliability assurance, and continuous process improvement, manufacturers can significantly elevate their PCB quality standards.

1. Understanding the Types of PCB Defects

To improve PCB quality inspection, it’s essential to have a comprehensive understanding of the various defects that can occur during the manufacturing process.

Common PCB Defects

- Open Circuits: Breaks in the conductive paths that prevent electrical flow.

- Short Circuits: Unintended connections between two or more circuit elements.

- Solder Bridges: Excess solder forming unwanted connections between pads or tracks.

- Component Misalignment: Incorrect positioning of components on the board.

- Delamination: Separation of the PCB layers due to heat or moisture.

- Copper Traces Issues: Including under-etching, over-etching, or mouse bites.

- Via Defects: Such as blocked vias or insufficient plating.

Classification of Defects

PCB defects can be broadly classified into two categories:

- Visual Defects: These are issues that can be detected through visual inspection, such as misaligned components, solder bridges, or physical damage to the board.

- Electrical Defects: These defects affect the electrical performance of the PCB and may not be visible to the naked eye. Examples include open circuits, short circuits, and impedance issues.

Importance of Root Cause Analysis

Understanding the root causes of defects is crucial for long-term quality improvement. By identifying patterns and common sources of defects, manufacturers can implement preventive measures and refine their processes. Root cause analysis should be an integral part of the quality inspection workflow, involving cross-functional teams from design, manufacturing, and quality assurance.

Read more about:

2. Standardizing Inspection Criteria

Consistency in quality inspection is key to maintaining high standards across production runs. Standardizing inspection criteria provides a clear benchmark for quality and helps in training inspectors effectively.

Importance of Clear Quality Standards

Industry-recognized standards such as IPC-A-600 (Acceptability of Printed Boards) and IPC-A-610 (Acceptability of Electronic Assemblies) provide comprehensive guidelines for PCB quality. These standards cover various aspects of PCB manufacturing and assembly, including:

- Dimensional tolerances

- Soldering quality

- Component placement

- Surface finishes

- Cleanliness requirements

Adhering to these standards ensures that your PCBs meet industry-accepted quality levels and facilitates communication with customers and suppliers.

Customizing Standards for Specific Requirements

While industry standards provide an excellent baseline, many products require additional or more stringent criteria. Customizing inspection standards based on specific product requirements is essential, especially for high-reliability applications such as medical devices, aerospace, or automotive electronics.

Consider the following when customizing standards:

- Environmental conditions the PCB will face (temperature, humidity, vibration)

- Expected lifespan of the product

- Regulatory requirements specific to the industry

- Customer specifications and expectations

Documenting Inspection Protocols and Defect Tolerances

Clear documentation of inspection protocols and defect tolerances is crucial for consistent quality control. This documentation should include:

- Detailed inspection procedures for each stage of production

- Acceptable limits for various types of defects

- Decision trees for classifying and handling defects

- Guidelines for when to reject a board or batch

- Procedures for reporting and escalating quality issues

Regularly review and update these documents to reflect process improvements and changes in product requirements.

3. Investing in the Right Inspection Methods

Choosing the appropriate inspection methods is crucial for effective quality control. Each method has its strengths and is suited to different stages of the production process.

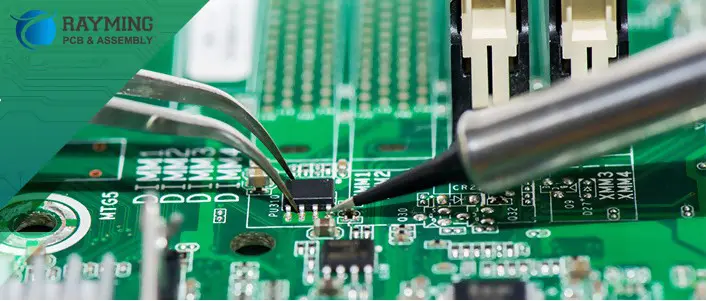

Manual Visual Inspection (MVI)

Pros and Cons

Pros:

- Low initial investment

- Flexibility to adapt to different products

- Ability to detect subtle defects that automated systems might miss

Cons:

- Prone to human error and fatigue

- Inconsistent results between inspectors

- Time-consuming for high-volume production

Best Practices to Reduce Human Error

- Implement regular breaks to combat fatigue

- Use magnification tools and proper lighting

- Rotate inspectors between different tasks

- Conduct regular refresher training

Automated Optical Inspection (AOI)

How AOI Systems Work

AOI systems use high-resolution cameras and sophisticated image processing algorithms to detect visual defects. They compare the captured images of PCBs against a “golden” reference to identify anomalies.

When to Implement AOI

- For high-volume production where speed is essential

- When dealing with complex, densely populated boards

- To ensure consistency in inspection quality

- As a complement to manual inspection for critical areas

Automated X-ray Inspection (AXI)

X-ray inspection is invaluable for detecting hidden defects, particularly in multi-layer boards and for inspecting solder joints under components like Ball Grid Arrays (BGAs).

Use Cases for AXI

- Inspecting solder joints in BGAs, QFNs, and other hidden connections

- Detecting voids in solder joints

- Checking internal layers of multi-layer PCBs

- Identifying counterfeit components

Flying Probe Testing / In-Circuit Testing (ICT)

These methods test the electrical functionality of PCBs, complementing visual inspection techniques.

Flying Probe Testing

- Ideal for low to medium volume production

- Flexible and requires minimal fixture costs

- Can test both assembled and bare boards

In-Circuit Testing (ICT)

- Suited for high-volume production

- Requires custom fixtures but offers faster test times

- Provides comprehensive electrical testing of components and connections

Functional Testing

As the final stage of validation, functional testing ensures that the PCB performs as intended in its actual application environment.

Key Aspects of Functional Testing

- Simulates real-world operating conditions

- Verifies overall functionality and performance

- Identifies issues that may not be apparent through other inspection methods

4. Improving Inspector Training and Certification

The quality of inspection is directly related to the skill and knowledge of the inspectors. Investing in comprehensive training and certification programs is essential for maintaining high standards.

Regular Training Programs

- Conduct periodic training on new defect types and emerging technologies

- Use real-world examples and case studies to enhance learning

- Implement hands-on training with a variety of PCB types and defects

Emphasis on Attention to Detail and Pattern Recognition

- Develop exercises to improve visual acuity and pattern recognition skills

- Train inspectors to recognize subtle variations that may indicate defects

- Encourage a methodical approach to inspection to ensure thoroughness

Certification Programs

- Implement industry-recognized certifications such as IPC-A-610 Certified IPC Specialist

- Develop in-house certification programs tailored to your specific products and processes

- Regularly assess and recertify inspectors to ensure skills remain current

5. Optimizing Inspection Process Flow

Efficient organization of the inspection process can significantly impact overall quality and productivity.

Inline vs. Offline Inspection

Inline Inspection

- Integrates inspection directly into the production line

- Provides immediate feedback and reduces handling

- Ideal for high-volume production with consistent product types

Offline Inspection

- Allows for more detailed inspection without impacting line speed

- Suitable for complex boards or when additional time is needed for thorough checks

- Can be used for random sampling or as a secondary inspection step

Strategic Placement of Inspections

Implement a multi-stage inspection strategy:

- Pre-solder Inspection: Check component placement and board condition before soldering

- Post-solder Inspection: Verify solder joint quality and component alignment after soldering

- Final Inspection: Comprehensive check of the assembled PCB before functional testing

Using Sampling Plans Effectively

For high-volume production, 100% inspection may not be feasible. Implement statistical sampling plans:

- Use AQL (Acceptable Quality Limit) standards to determine sample sizes

- Implement tightened, normal, and reduced inspection levels based on historical quality data

- Adjust sampling frequency based on the criticality of the product and process stability

6. Using Data-Driven Quality Control

Leveraging data analytics can provide valuable insights for continuous improvement of PCB quality.

Defect Tracking Systems and Software

- Implement robust defect tracking software to log and categorize all identified issues

- Use barcode or RFID systems to track individual boards through the inspection process

- Generate real-time reports on defect rates and types

Statistical Process Control (SPC) and Trend Analysis

- Use SPC charts to monitor key quality indicators over time

- Identify trends and patterns in defect occurrences

- Set control limits and implement corrective actions when processes deviate

Root Cause and Corrective Action (RCCA) Feedback Loops

- Establish a formal RCCA process for addressing recurring quality issues

- Involve cross-functional teams in problem-solving sessions

- Document and share lessons learned to prevent future occurrences

7. Continuous Improvement and Innovation

Quality inspection should be viewed as an evolving process, constantly adapting to new challenges and technologies.

Implementing Lessons Learned

- Regularly review inspection data and customer feedback to identify areas for improvement

- Update inspection criteria and processes based on new insights

- Share best practices across different production lines and facilities

Regular Process Audits and Supplier Inspections

- Conduct periodic audits of your inspection processes to ensure adherence to standards

- Extend quality requirements to suppliers and perform regular supplier audits

- Collaborate with suppliers to improve incoming material quality

Exploring AI and Machine Learning for Predictive Quality Inspection

- Investigate AI-powered defect detection systems for more accurate and faster inspections

- Use machine learning algorithms to predict potential quality issues based on historical data

- Implement predictive maintenance for inspection equipment to minimize downtime

8. Collaboration Between Design and Manufacturing Teams

Effective PCB quality inspection starts at the design stage. Fostering collaboration between design and manufacturing teams can preemptively address many quality issues.

Importance of Design for Manufacturability (DFM) Reviews

- Conduct regular DFM reviews to identify potential manufacturing challenges early

- Use DFM software tools to analyze designs for compliance with manufacturing capabilities

- Establish clear communication channels between design and manufacturing teams

Early Detection of Design Issues

- Implement simulation tools to predict potential defects or reliability issues

- Create prototypes or use 3D printing to validate designs before full production

- Encourage feedback from manufacturing and quality teams during the design phase

Conclusion

Improving PCB quality inspection is a multifaceted endeavor that requires a holistic approach. By understanding defect types, standardizing criteria, investing in appropriate inspection methods, and fostering a culture of continuous improvement, manufacturers can significantly enhance their PCB quality.

Remember that rigorous PCB inspection is not just about catching defects; it’s about driving overall quality improvement throughout the entire manufacturing process. By treating inspection as an integral part of your quality management system rather than a final checkpoint, you can achieve higher reliability, reduce costs, and ultimately deliver superior products to your customers.

As technology continues to evolve, so too must PCB inspection methods. Stay informed about emerging technologies and industry trends, and be prepared to adapt your inspection processes accordingly. With a commitment to excellence and a data-driven approach to quality, you can position your PCB manufacturing operation at the forefront of the industry, ready to meet the challenges of tomorrow’s electronic devices.