PCB Prototype in 24 Hours: Best Services, Costs & Quality Comparison 2025

RayMing leverages over 20 years of PCB manufacturing experience to provide rapid, budget-friendly prototyping solutions.

Introduction

In electronics industry, time-to-market can make or break a product launch. Whether you’re a startup racing to secure funding, an established company launching a new product line, or an engineer validating a critical design, getting high-quality PCB prototypes within 24 hours has become not just a luxury, but often a necessity.

The PCB prototyping landscape has evolved dramatically over the past few years. What once required weeks of lead time can now be accomplished in hours, thanks to advances in manufacturing technology, streamlined processes, and fierce competition among prototype manufacturers. However, with speed comes trade-offs in cost, quality, and design complexity limitations.

This comprehensive guide will navigate you through the best PCB prototype services available in 2025, comparing their capabilities, costs, quality standards, and real-world performance. We’ll examine which services truly deliver on their 24-hour promises and help you make informed decisions for your next project.

The 24-Hour PCB Prototype Market Overview

Market Evolution and Current State

The demand for ultra-fast PCB prototyping has exploded in recent years. According to industry reports, the global PCB prototype market has grown by over 15% annually, with 24-hour services representing the fastest-growing segment. This growth is driven by several factors:

- Shorter product development cycles: Companies are under pressure to reduce time-to-market from months to weeks

- Agile hardware development: The adoption of agile methodologies in hardware design requires rapid iteration

- Investor expectations: Startups need functional prototypes for funding rounds and demonstrations

- Supply chain disruptions: COVID-19 and other global events have made local, fast prototyping more valuable

Technology Enablers

Several technological advances have made 24-hour PCB prototyping feasible:

- Advanced CAM software: Automated design rule checking and optimization reduce manual intervention

- High-speed drilling and routing: Modern CNC equipment can process boards 3-5x faster than previous generations

- Improved plating processes: Faster electroplating and surface finishing techniques

- Automated optical inspection (AOI): Real-time quality control without slowing production

- Digital workflow integration: Seamless file transfer and processing from design to manufacturing

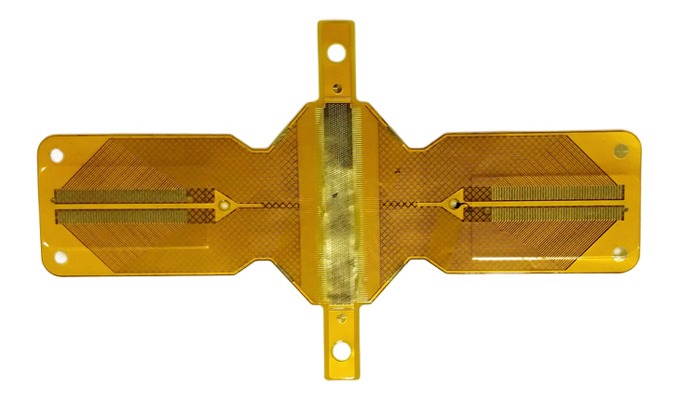

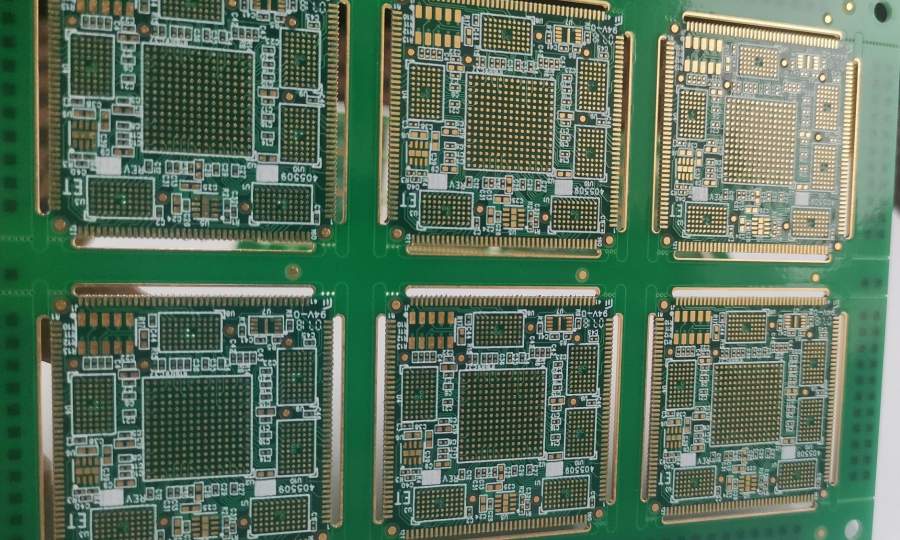

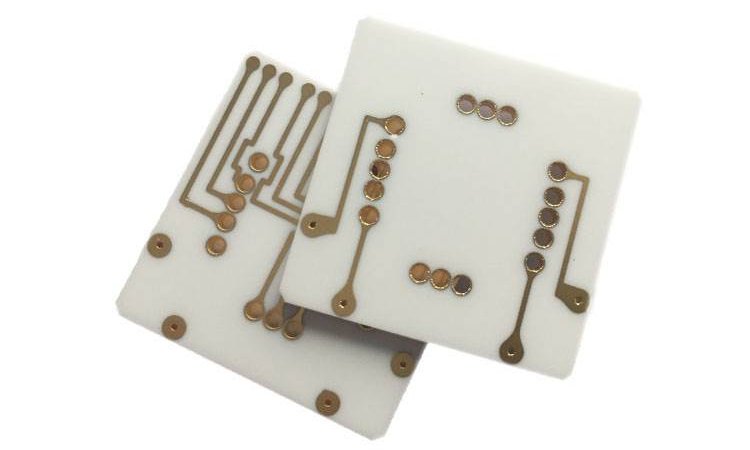

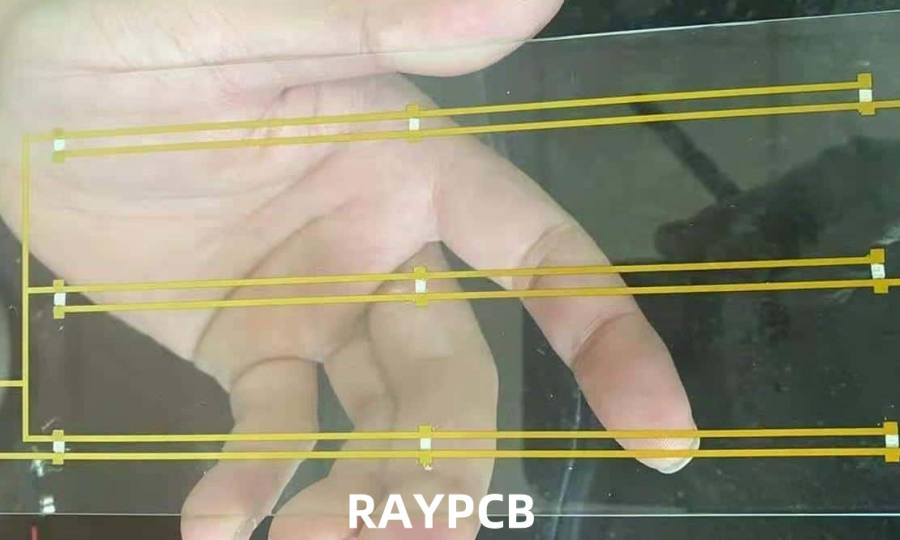

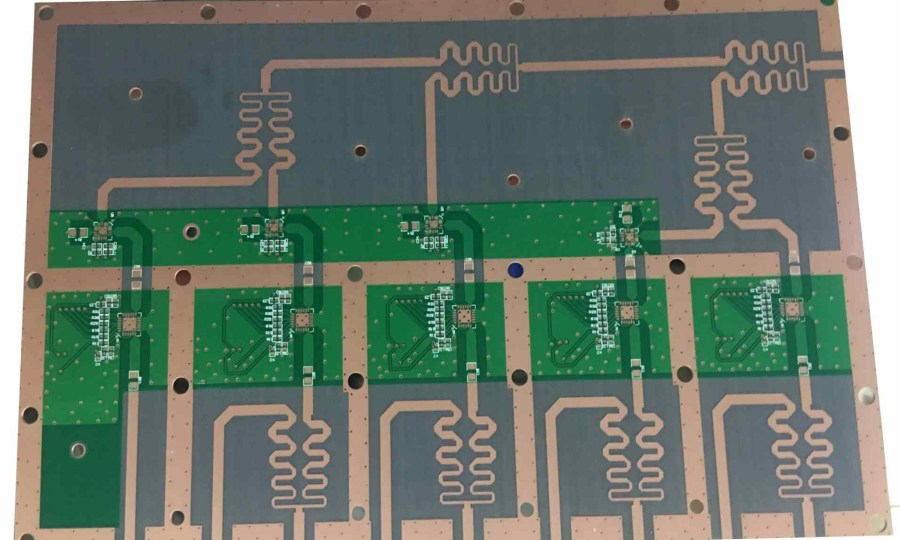

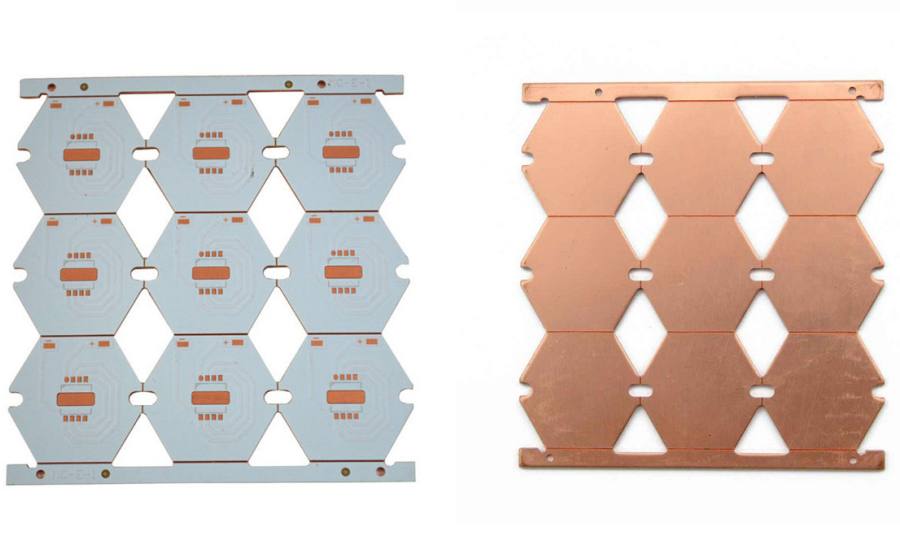

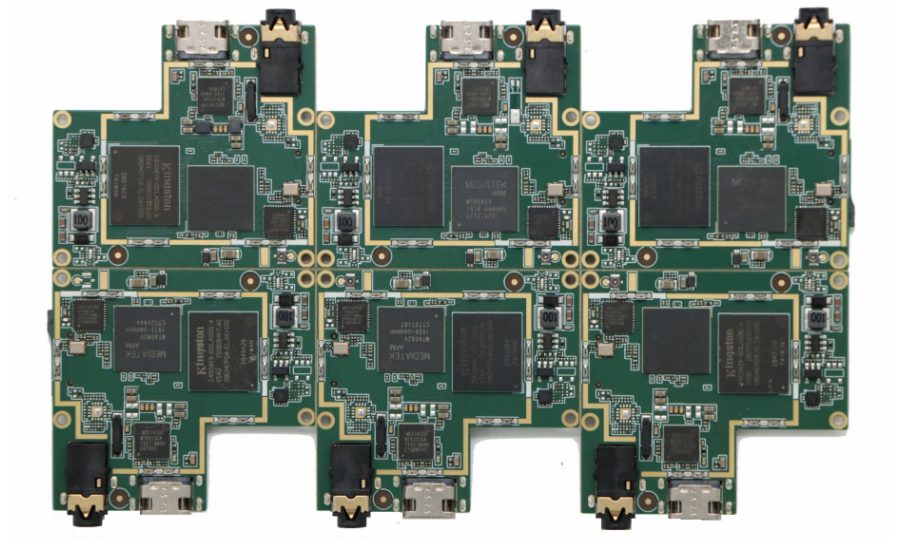

PCB Prototype We Served

Top PCB Prototype Services for 24-Hour Delivery

1. PCBWay – The Speed Champion

Overview: PCBWay has positioned itself as a leader in fast-turnaround prototyping, consistently delivering quality boards within their promised timeframes.

Capabilities:

- Standard Turnaround: 24 hours for simple 2-layer boards

- Layer Count: Up to 6 layers in 24 hours

- Board Size: Maximum 100mm x 80mm for fastest service

- Minimum Trace/Space: 6/6 mil

- Via Size: Minimum 0.2mm drill

- Material Options: FR4, Rogers (limited), Aluminum

- Surface Finish: HASL, ENIG (add 12 hours), OSP

Pricing Structure (2025 rates):

- 2-layer, 50mm x 50mm: $45-65 for 5 pieces

- 4-layer, 50mm x 50mm: $85-120 for 5 pieces

- 6-layer, 50mm x 50mm: $150-200 for 5 pieces

- Rush fee: $30-50 depending on complexity

Quality Standards:

- IPC Class 2 standard

- 100% electrical testing

- AOI for all boards

- Impedance control: ±10%

Pros:

- Consistent delivery times

- Good customer support

- Reasonable pricing for speed

- User-friendly online interface

Cons:

- Limited advanced materials in 24-hour service

- Size restrictions for fastest turnaround

- Additional costs for tight tolerances

2. JLCPCB – The Volume Leader

Overview: JLCPCB has revolutionized the prototyping industry with their scale and automation, offering some of the most competitive prices in the market.

Capabilities:

- Standard Turnaround: 24 hours for 2-4 layer boards

- Layer Count: Up to 4 layers guaranteed in 24 hours

- Board Size: Up to 100mm x 100mm

- Minimum Trace/Space: 5/5 mil

- Via Size: Minimum 0.15mm drill

- Material Options: FR4 primarily, limited specialty materials

- Surface Finish: HASL, ENIG (add time), OSP

Pricing Structure (2025 rates):

- 2-layer, 100mm x 100mm: $20-35 for 5 pieces

- 4-layer, 100mm x 100mm: $55-75 for 5 pieces

- Express fee: $20-30

Quality Standards:

- IPC Class 2

- Automated testing

- Statistical quality control

- High-volume consistency

Pros:

- Extremely competitive pricing

- Large size capability

- Integrated assembly services

- Proven track record

Cons:

- Limited material options

- Customer service can be inconsistent

- Quality can vary with extreme rush orders

3. RayPCB – The Precision Specialist

Overview: RayPCB focuses on high-quality prototypes for demanding applications, particularly popular among the maker and professional communities in the China.

Capabilities:

- Standard Turnaround: 2-3 days, 24-hour service available for premium

- Layer Count: Up to 8 layers in express service

- Board Size: Various size options

- Minimum Trace/Space: 5/5 mil standard, 3/3 mil available

- Material Options: High-quality FR4, Rogers, specialty materials

- Surface Finish: ENIG standard, excellent quality

Pricing Structure (2025 rates):

- 2-layer boards: $15-25 per square inch

- 4-layer boards: $30-45 per square inch

- 24-hour rush: 200% surcharge

Quality Standards:

- IPC Class 2/3 capability

- Excellent surface finish quality

- Tight tolerance control

- Purple soldermask (signature)

Pros:

- Exceptional quality

- Consistent results

- Maker-friendly policies

Cons:

- Higher pricing

- Limited 24-hour availability

- Smaller scale operation

4. Advanced Circuits – The Reliability Expert

Overview: Advanced Circuits has built a reputation for consistent quality and reliability, particularly strong in the aerospace and defense sectors.

Capabilities:

- Standard Turnaround: 24 hours available for select designs

- Layer Count: Up to 8 layers with express service

- Board Size: Large board capability

- Minimum Trace/Space: 4/4 mil

- Material Options: Wide range including military-grade

- Surface Finish: All standard finishes available

Pricing Structure (2025 rates):

- Premium pricing reflecting quality

- 2-layer express: $80-120 for small boards

- 24-hour surcharge: $100-200 depending on complexity

Quality Standards:

- IPC Class 3 capability

- Military specifications

- Comprehensive testing

- Certified processes

Pros:

- Highest quality standards

- Military/aerospace qualified

- Comprehensive capabilities

- Excellent customer service

Cons:

- Premium pricing

- May be overkill for simple prototypes

- Longer quote process

5. Seeed Studio Fusion – The Ecosystem Player

Overview: Seeed Studio offers integrated prototyping services as part of their broader hardware ecosystem, popular among makers and IoT developers.

Capabilities:

- Standard Turnaround: 24-48 hours for standard designs

- Layer Count: Up to 6 layers in express

- Board Size: Competitive size limits

- Minimum Trace/Space: 6/6 mil

- Material Options: Standard FR4, some specialty options

- Additional Services: Assembly, enclosures, components

Pricing Structure (2025 rates):

- Competitive with JLCPCB

- 2-layer: $25-40 for basic sizes

- Integrated services discounts available

Quality Standards:

- IPC Class 2

- Good consistency

- Integrated quality control

Pros:

- Ecosystem integration

- Good maker community support

- Reasonable pricing

- Additional services available

Cons:

- Less specialized in pure PCB work

- Variable delivery times

- Limited advanced capabilities

Cost Analysis and Value Comparison

Understanding PCB Prototype Pricing

PCB prototype pricing in the 24-hour market is influenced by several key factors:

Base Factors:

- Layer count (2-layer vs 4-layer vs 6+ layer)

- Board size and panelization efficiency

- Minimum trace width and spacing requirements

- Via size and type (through-hole vs buried/blind)

- Surface finish type and quality

Rush Service Premiums:

- 24-hour service typically adds 50-200% to base price

- Some manufacturers include rush in base pricing

- Peak demand periods may increase rush charges

Hidden Costs to Consider:

- Shipping and handling (can be $15-50 for express)

- Design rule check failures and revisions

- Setup fees for small quantities

- Currency fluctuations for overseas manufacturers

2025 Pricing Benchmarks

Based on current market analysis, here are typical pricing ranges for common prototype scenarios:

Simple 2-Layer Board (50mm x 50mm, 5 pieces):

- Budget option: $20-35 + shipping

- Standard quality: $35-55 + shipping

- Premium quality: $60-100 + shipping

4-Layer Board (50mm x 50mm, 5 pieces):

- Budget option: $50-75 + shipping

- Standard quality: $75-120 + shipping

- Premium quality: $120-200 + shipping

Complex 6-Layer Board (75mm x 75mm, 5 pieces):

- Standard quality: $150-250 + shipping

- Premium quality: $250-400 + shipping

Value Optimization Strategies

To maximize value when ordering 24-hour prototypes:

- Batch multiple revisions: If possible, combine multiple design iterations

- Optimize panel utilization: Design boards to fit standard panel sizes efficiently

- Choose appropriate quality level: Don’t over-spec for early prototypes

- Consider assembly integration: Some manufacturers offer better deals for PCB+assembly

- Plan for shipping: Factor express shipping costs into total project budget

Quality Standards and Considerations

Understanding Quality Classifications

IPC Class 1 (General Electronic Products):

- Suitable for non-critical applications

- Rarely offered for prototypes

- Lowest cost option when available

IPC Class 2 (Dedicated Service Electronic Products):

- Standard for most prototype applications

- Good balance of quality and cost

- Suitable for most commercial products

IPC Class 3 (High Performance Electronic Products):

- Required for critical applications

- Higher inspection standards

- Necessary for aerospace, medical, military

Quality Control Processes in 24-Hour Manufacturing

Automated Optical Inspection (AOI):

- Real-time defect detection

- Critical for maintaining speed without sacrificing quality

- Catches 90%+ of manufacturing defects

Electrical Testing:

- Open/short circuit testing on all boards

- Impedance testing for controlled impedance designs

- In-circuit testing for complex boards

Visual Inspection:

- Manual inspection for critical defects

- Sample-based inspection for high-volume runs

- Final quality gate before shipping

Common Quality Issues in Rush Orders

Etching Problems:

- Under-etched traces (too wide)

- Over-etched traces (too narrow)

- Ragged trace edges

Drilling Issues:

- Hole size variations

- Rough hole walls

- Positional accuracy problems

Plating Defects:

- Thin plating in holes

- Uneven surface finish

- Contamination issues

Prevention Strategies:

- Provide clear, detailed specifications

- Use conservative design rules for rush orders

- Request pre-production samples for critical projects

- Build in testing time for prototype validation

Design Considerations for 24-Hour Turnaround

Design Rules for Speed

To ensure successful 24-hour prototype delivery, follow these design guidelines:

Trace Width and Spacing:

- Minimum 6/6 mil for most manufacturers

- 8/8 mil for highest reliability

- Avoid minimum rules unless necessary

Via Specifications:

- 0.2mm (8 mil) minimum drill size

- 0.45mm (18 mil) minimum finished hole

- Standard via-in-pad avoided when possible

Layer Stack-up Considerations:

- Use standard stack-ups when possible

- Avoid exotic dielectric materials

- Standard copper weights (0.5oz, 1oz, 2oz)

Component Footprints:

- Use standard component libraries

- Avoid experimental or custom footprints

- Ensure adequate spacing for assembly

File Preparation Best Practices

Gerber Files:

- Use latest Gerber format (RS-274X)

- Include all necessary layers

- Verify files with free viewers before submission

Drill Files:

- Excellon format preferred

- Include tool definitions

- Merge slots and holes appropriately

Documentation:

- Clear fabrication notes

- Specify critical dimensions

- Include assembly drawings if relevant

Design Rule Check (DRC):

- Run comprehensive DRC before submission

- Address all violations or provide justification

- Use manufacturer-specific rules when available

Shipping and Logistics

Delivery Options and Timelines

Standard Express Shipping:

- 1-2 day delivery within continental regions

- Cost: $15-30 for small packages

- Tracking included

Overnight/Next-Day Delivery:

- Guaranteed next business day

- Cost: $30-75 depending on size/weight

- Insurance typically included

International Shipping:

- Express international: 2-5 days

- Cost: $40-150 depending on destination

- Customs clearance considerations

Geographic Considerations

North American Manufacturers:

- Faster delivery to US/Canada

- No customs delays

- Higher labor costs reflected in pricing

Asian Manufacturers:

- Excellent pricing

- Longer shipping times

- Potential customs issues

European Options:

- Growing market presence

- Competitive for EU customers

- Limited 24-hour options currently

Industry Applications and Use Cases

Startup and Entrepreneurship

Prototype for Funding:

- Investor demonstrations require functional hardware

- Multiple iterations before pitches

- Cost sensitivity due to limited budgets

Market Validation:

- Quick prototype testing with potential customers

- Rapid iteration based on feedback

- Time-to-market pressure

Case Study: A Y Combinator startup used 24-hour PCB prototyping to iterate through 12 design revisions in 3 weeks, ultimately securing $2M in seed funding with a working prototype demonstration.

Consumer Electronics

Product Development Cycles:

- Seasonal product launches (back-to-school, holiday seasons)

- Competitive response requirements

- Feature validation and testing

Engineering Validation:

- Signal integrity verification

- Thermal testing

- EMC pre-compliance testing

Industrial and IoT Applications

Field Trial Preparation:

- Quick deployment of test units

- Remote monitoring capability validation

- Environmental testing preparation

Customer-Specific Modifications:

- Rapid customization for client requirements

- Proof-of-concept demonstrations

- Integration testing with existing systems

Medical Device Development

Proof of Concept:

- Early-stage feasibility testing

- Regulatory pathway exploration

- Biocompatibility testing preparation

Clinical Trial Support:

- Limited production runs for trials

- Rapid iteration based on clinical feedback

- Regulatory submission support

Future Trends and 2025 Outlook

Technology Advancement Trends

Manufacturing Process Improvements:

- Additive manufacturing integration

- Advanced materials adoption

- AI-driven quality control

Design Tool Integration:

- Cloud-based design collaboration

- Real-time manufacturability feedback

- Automated design optimization

Supply Chain Innovation:

- Distributed manufacturing networks

- Local production capabilities

- Reduced shipping dependencies

Market Evolution Predictions

Consolidation Trends:

- Larger players acquiring smaller specialists

- Vertical integration of services

- Platform-based service delivery

Geographic Shifts:

- Nearshoring manufacturing capabilities

- Regional hub development

- Reduced reliance on single-country production

Service Expansion:

- Integrated design services

- End-to-end product development

- Subscription-based prototyping services

Emerging Technologies Impact

5G and IoT Growth:

- Higher frequency design requirements

- Smaller form factor demands

- Integrated antenna designs

Electric Vehicle Market:

- High-power electronics requirements

- Thermal management challenges

- Safety and reliability demands

AI and Machine Learning:

- Edge computing hardware needs

- Specialized processor interfaces

- Power efficiency optimization

Making the Right Choice: Decision Framework

Project Requirements Assessment

Timeline Criticality:

- How critical is the 24-hour delivery?

- What are the consequences of delay?

- Is there flexibility in the schedule?

Quality Requirements:

- What is the intended use of the prototype?

- Are there specific standards to meet?

- How critical is first-pass success?

Budget Constraints:

- What is the total project budget?

- How does prototyping cost impact overall project?

- Are there opportunities for cost optimization?

Technical Complexity:

- How complex is the PCB design?

- Are there special material requirements?

- What are the critical performance parameters?

Manufacturer Selection Criteria

Track Record and Reliability:

- Historical on-time delivery performance

- Customer reviews and testimonials

- Industry reputation and experience

Technical Capabilities:

- Design rule compatibility

- Material options and availability

- Quality control processes

Communication and Support:

- Responsiveness to inquiries

- Technical support availability

- Problem resolution capabilities

Total Cost of Ownership:

- Base pricing transparency

- Hidden fees and charges

- Shipping and handling costs

Risk Mitigation Strategies

Backup Plans:

- Identify secondary manufacturers

- Plan for potential delays

- Consider parallel processing

- Request process certifications

- Plan for incoming inspection

- Build in testing time

Communication Protocols:

- Establish clear contact points

- Set expectations for updates

- Plan for issue escalation

Conclusion and Recommendations

The 24-hour PCB prototype market in 2025 offers unprecedented opportunities for rapid hardware development, but success requires careful planning and informed decision-making. The landscape is dominated by several key players, each with distinct strengths and positioning.

For budget-conscious projects with standard requirements, JLCPCB and PCBWay offer excellent value propositions with reliable delivery and acceptable quality. Their scale and automation enable competitive pricing while maintaining reasonable quality standards.

For quality-critical applications where reliability is paramount, Advanced Circuits and OSH Park provide superior quality control and process consistency, though at premium pricing. These manufacturers are particularly valuable for applications where first-pass success is critical.

For integrated development needs where PCB prototyping is part of a larger hardware development ecosystem, Seeed Studio Fusion offers comprehensive services that can streamline the entire development process.

Key Success Factors

- Plan Early: Even with 24-hour capabilities, early planning prevents rushed decisions and design compromises

- Choose Appropriately: Match manufacturer capabilities to project requirements rather than defaulting to lowest cost

- Design for Manufacturing: Following manufacturer design rules prevents delays and quality issues

- Budget Comprehensively: Include all costs (shipping, testing, potential iterations) in project planning

- Build Relationships: Establishing relationships with reliable manufacturers pays dividends in critical situations

Looking Forward

The 24-hour PCB prototype market will continue evolving rapidly, driven by technological advancement and competitive pressure. Manufacturers are investing heavily in automation, quality control, and customer experience improvements. For customers, this means even better service, more competitive pricing, and expanding capabilities.

The key to success in this environment is staying informed about manufacturer capabilities, maintaining realistic expectations about what can be achieved in 24 hours, and building robust development processes that leverage these rapid prototyping capabilities effectively.

As we move through 2025, the companies that best combine speed, quality, and value while maintaining excellent customer relationships will dominate this critical market segment. For hardware developers, the abundance of quality options means that 24-hour PCB prototyping can be a reliable tool in the development toolkit, enabling faster innovation and shorter time-to-market across all industry segments.

Whether you’re developing the next breakthrough IoT device, creating innovative medical technology, or building the future of consumer electronics, the 24-hour PCB prototype services available in 2025 provide the speed and quality needed to turn ideas into reality at unprecedented pace.