Turnkey PCB Assembly: Reducing Costs and Time-to-Market for Electronics Companies

We offer comprehensive PCB assembly services, including both complete turnkey solutions and partial assembly options. Please specify which components you will provide and which should remain unmounted.

In today’s fiercely competitive electronics landscape, speed is crucial in electronics manufacturing, especially in consumer electronics, medical devices, and automotive industries. Companies face mounting pressure to deliver innovative products faster while maintaining quality and controlling costs. Traditional PCB assembly approaches—juggling multiple vendors, managing complex supply chains, and coordinating disparate processes—are no longer sustainable in this environment.

Enter turnkey PCB assembly, a transformative solution that’s revolutionizing how electronics companies approach manufacturing. This comprehensive service model consolidates every aspect of PCB production under one roof, from initial component sourcing to final product delivery. For electronics companies seeking to streamline operations, reduce overhead, and accelerate time-to-market, turnkey PCB assembly represents a strategic competitive advantage that can make the difference between market leadership and obsolescence.

Understanding Turnkey PCB Assembly: A Complete Solution

Turnkey PCB assembly is a comprehensive service where a single supplier handles all aspects of PCB production, from sourcing components to final product assembly and shipping. Unlike traditional manufacturing approaches that require coordinating with multiple vendors—one for PCB fabrication, another for component procurement, and yet another for assembly—turnkey solutions provide a seamless, integrated experience.

The term “turnkey” derives from the concept of delivering a complete, ready-to-use solution. The meaning of “turnkey” projects is any product or service that comes ready for the buyer to operate. In PCB assembly, this translates to receiving fully assembled, tested circuit boards without the complexity of managing multiple suppliers or coordinating various manufacturing stages.

The Evolution of PCB Manufacturing

The global PCB market is experiencing unprecedented growth, driven by technological advancement and increasing demand across industries. The Printed Circuit Board Industry is expected to grow from USD 84.24 billion in 2025 to USD 106.85 billion by 2030, at a CAGR of 4.87% during the forecast period. This growth is fueled by emerging technologies such as 5G, IoT, and AI, all of which require sophisticated PCB solutions.

The increasing integration of miniaturized and energy-efficient electronic devices and the expansion of 5G technology, IoT-enabled devices, and autonomous vehicles are driving the demand for advanced PCBs. In this rapidly evolving landscape, companies need manufacturing partners who can adapt quickly to technological changes while maintaining consistent quality and competitive pricing.

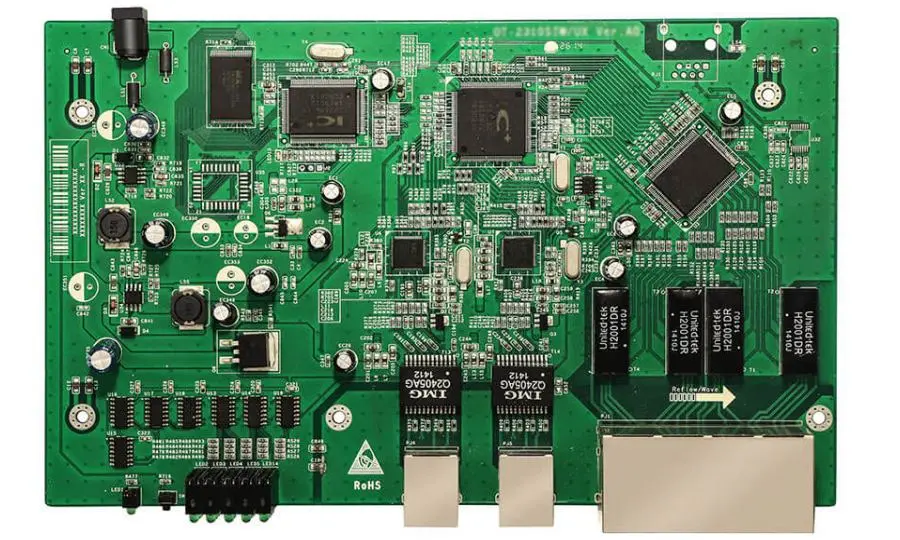

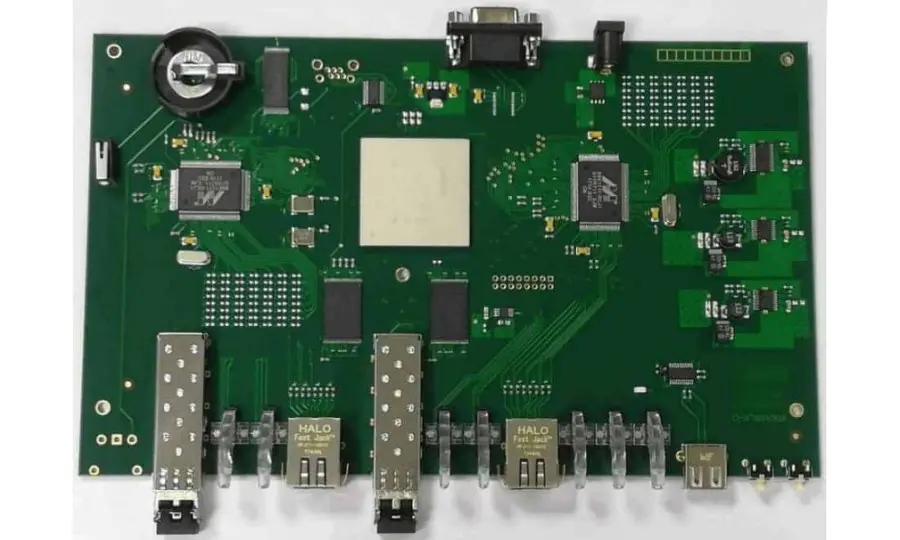

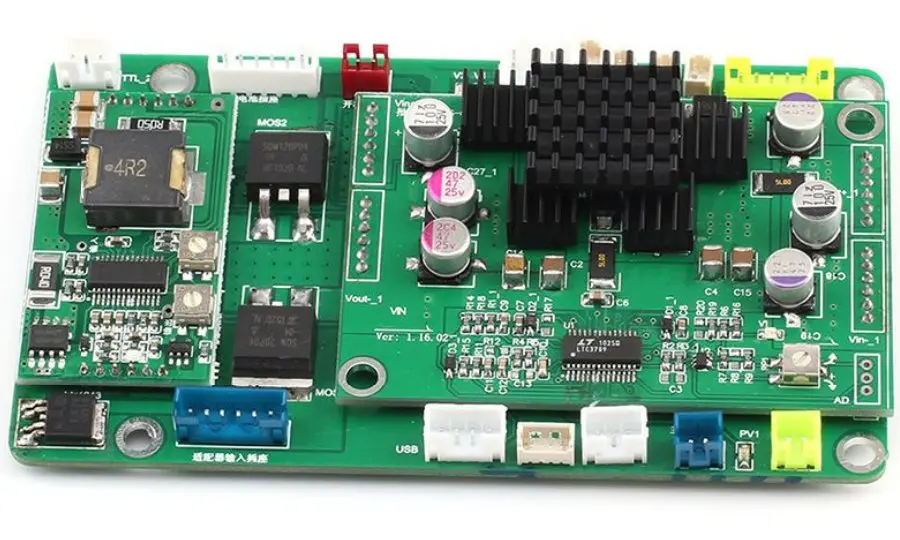

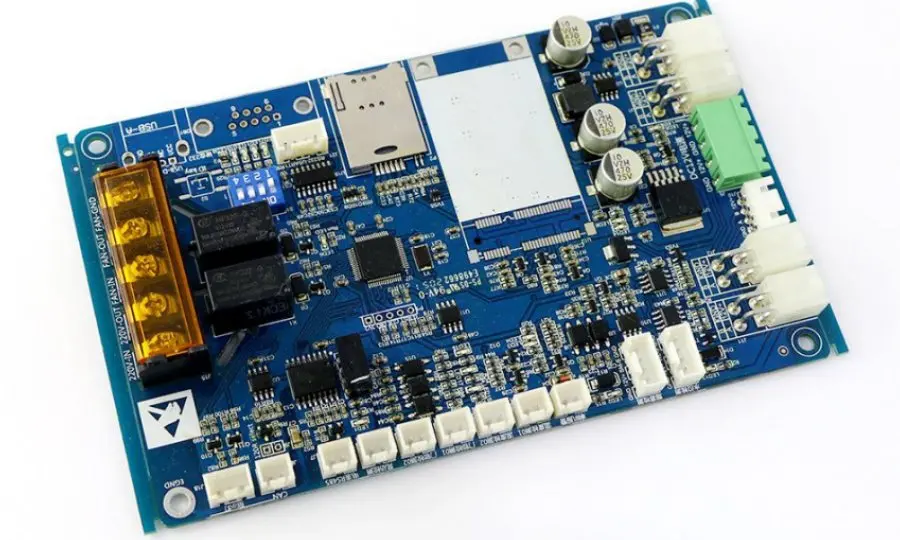

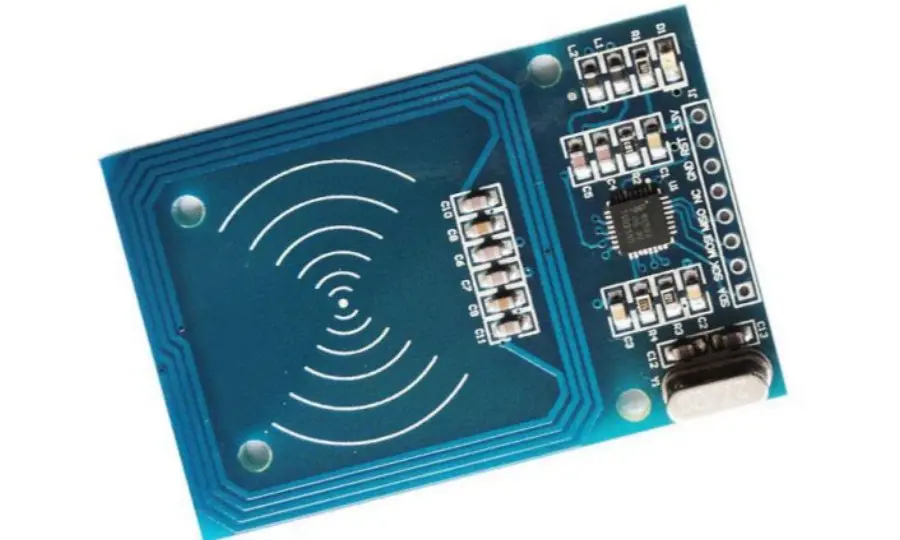

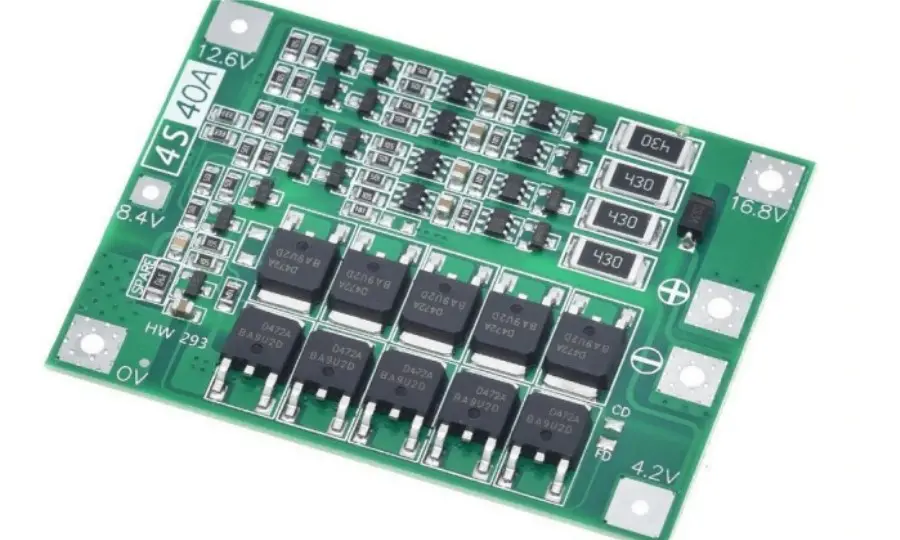

Turnkey PCBA We Served

Full vs. Partial Turnkey Assembly: Choosing Your Strategy

Understanding the distinction between full and partial turnkey assembly is crucial for making informed decisions about your manufacturing approach.

Full Turnkey Assembly

Full Turnkey PCB Assembly is a type of PCB assembly service where the manufacturer provides all the components and materials required for the assembly process. This comprehensive approach includes:

- Complete component procurement from trusted supplier networks

- PCB fabrication using appropriate materials and specifications

- Assembly services including SMT, through-hole, and mixed technology

- Quality testing and inspection at multiple stages

- Packaging and shipping directly to end customers

The primary advantage of full turnkey assembly lies in its simplicity and efficiency. The smoothest perk of this opportunity lies in time and energy savings on your behalf. Companies can focus entirely on product development and market strategy while their manufacturing partner handles all production complexities.

Partial Turnkey Assembly

In a partial turn-key assembly setup, the service provider only takes responsibility for certain aspects of the assembly process. The client typically supplies some components, while the assembly provider procures the rest and assembles the PCB. This hybrid model offers several strategic advantages:

- Cost control through selective component sourcing

- Supplier relationship leverage for specialized or proprietary components

- Flexibility in managing critical component inventory

- Risk mitigation for components subject to supply chain disruptions

If you have special agreements or preferential pricing with specific component manufacturers, a partial turnkey solution enables you to utilize those relationships while still benefiting from professional assembly services.

Decision Framework: Full vs. Partial Turnkey

The choice between full and partial turnkey assembly depends on several key factors:

Choose Full Turnkey When:

- You’re launching new products without existing component relationships

- Time-to-market is the primary concern

- You prefer simplified supply chain management

- Your team lacks extensive procurement expertise

Choose Partial Turnkey When:

- You have strategic supplier relationships for key components

- Cost optimization is a primary objective

- You maintain significant component inventory

- You require specific component certifications or specifications

Cost Reduction: The Economic Advantage of Turnkey Assembly

One of the most compelling benefits of turnkey PCB assembly is its potential for significant cost reduction across multiple dimensions of manufacturing operations.

Direct Cost Savings

By consolidating all aspects of production into a single PCB manufacturing company, businesses can reduce shipping costs associated with transporting components between multiple suppliers, minimize overhead costs related to managing different vendors, and leverage volume discounts on components due to the manufacturer’s existing supplier relationships.

Traditional multi-vendor approaches often result in hidden costs that many companies underestimate. These include:

- Administrative overhead for managing multiple supplier relationships

- Quality control complexity across different vendor standards

- Inventory carrying costs for components from various sources

- Expedited shipping fees when coordination fails

- Risk mitigation costs for supply chain disruptions

Turnkey providers are able to offer significant discounts on parts and labor. This is because they can purchase components in bulk and have a team of skilled workers who can quickly assemble your product.

Volume Purchasing Power

Established turnkey providers leverage their purchasing power to secure better component pricing than individual companies can achieve. By establishing strong relationships, you can potentially secure competitive costs without compromising quality. This advantage becomes particularly pronounced for smaller companies that lack the volume to negotiate favorable terms with component distributors.

Design for Manufacturing (DFM) Cost Optimization

Turnkey providers bring valuable DFM expertise that can result in substantial cost savings during the design phase. Select components with standard sizes, adhere to DFA guidelines, and perform cost-benefit analysis are fundamental principles that experienced turnkey partners implement to optimize manufacturing costs.

Key DFM cost reduction strategies include:

- Standardized component selection to minimize assembly complexity

- Optimized board layouts to reduce material waste

- Component placement optimization to streamline assembly processes

- Test point placement to facilitate efficient quality control

Some simple parts swaps can help get you across the finish line and reach a further cost reduction: No-lead components tend to bring extra costs due to inspection needs, as well as potential for rework when there are solder defects.

Long-term Cost Benefits

Beyond immediate cost savings, turnkey assembly provides long-term economic advantages through:

Reduced Total Cost of Ownership (TCO): Having your electronics box build project spread out among several electronic assembly vendors may save money in the short term, but rush and expedited shipping fees are killing your overall budget.

Risk Mitigation: Professional turnkey providers assume responsibility for quality issues, reducing potential costs associated with defects, recalls, or rework.

Scalability: Established turnkey relationships facilitate easier scaling from prototype to high-volume production without the need to rebuild supplier networks.

Accelerating Time-to-Market: Speed as a Competitive Advantage

In today’s fast-paced electronics market, time-to-market can determine the success or failure of new products. In a fast-evolving industry like consumer electronics, updates and iterations are common. A turnkey PCB manufacturer should be able to leverage their production advantages to adapt to changes or design modifications quickly.

Streamlined Project Management

Turnkey PCB assembly accelerates product delivery by eliminating time-consuming procurement processes, reducing communication delays between multiple vendors, and ensuring seamless coordination between design, fabrication, and assembly teams.

Traditional multi-vendor approaches often create bottlenecks through:

- Extended communication chains requiring coordination between multiple parties

- Sequential processing delays as projects move between different vendors

- Quality control checkpoints at each vendor handoff

- Shipping and logistics delays between manufacturing stages

Rapid Prototyping Capabilities

Sierra Circuits can provide full turnkey boards in as fast as 5 days, demonstrating the speed advantages possible with integrated turnkey solutions. This rapid turnaround capability enables:

- Accelerated design iteration cycles

- Earlier validation of product concepts

- Faster response to market opportunities

- Reduced development timeline risks

Turn-key PCB providers can often rapidly produce prototypes, allowing for early detection and rectification of design flaws. This early intervention can save time and resources in the long run.

Production Scalability

The transition from prototype to production represents a critical phase where timing can impact market success. Full turnkey assembly reduces lead times, lowers costs and eliminates risks like component shortages or counterfeit parts, providing a seamless path from prototype to production.

Turnkey providers offer several advantages for scaling production:

- Pre-established component supply chains

- Validated assembly processes

- Consistent quality systems

- Flexible production capacity

Industry 4.0 and Manufacturing Automation

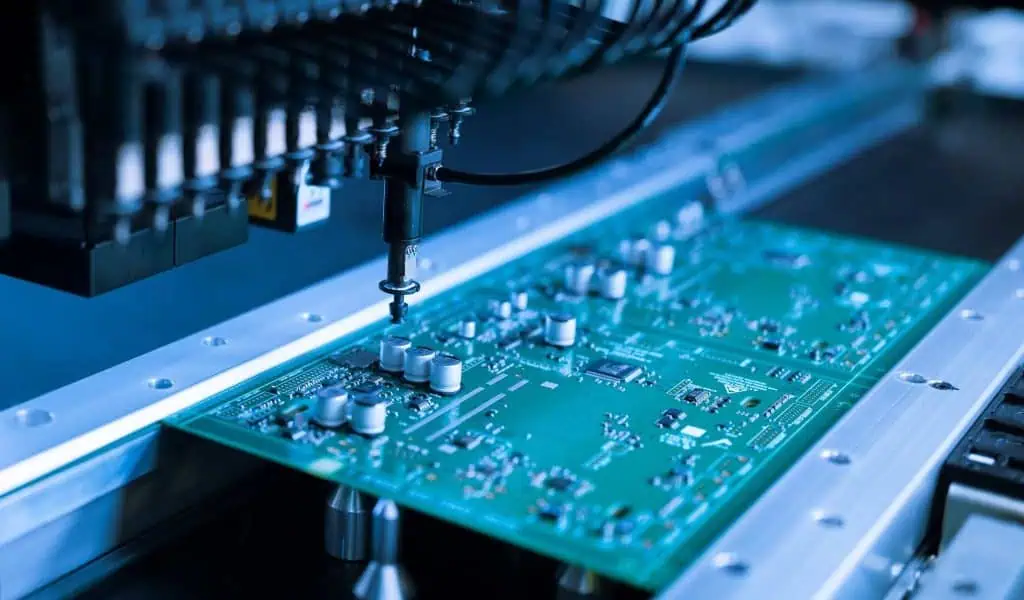

Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control.

Modern turnkey providers leverage advanced manufacturing technologies to deliver unprecedented speed and precision:

- Automated assembly lines for consistent throughput

- AI-driven quality control for real-time defect detection

- Predictive maintenance to minimize production disruptions

- Digital workflow management for optimized process coordination

Quality Assurance and Risk Mitigation

Quality control represents one of the most significant advantages of turnkey PCB assembly, as single-source responsibility creates enhanced accountability and comprehensive quality management.

Integrated Quality Systems

Since all processes occur within a single manufacturing ecosystem, there is greater control over quality at every stage, including component sourcing: Only high-quality, authentic components from trusted suppliers. This integrated approach eliminates quality gaps that can occur when multiple vendors with different standards collaborate.

Key quality advantages include:

Component Authentication: Turnkey providers maintain direct relationships with authorized distributors, reducing risks of counterfeit components that can plague multi-vendor supply chains.

Process Control: Bittele employs a number of strategies in Quality Management and process control to ensure that every PCB order is done right the first time.

Traceability: Complete visibility into component sources, assembly processes, and quality checkpoints throughout the manufacturing cycle.

Industry Certifications and Compliance

Professional turnkey providers maintain comprehensive certifications that ensure compliance with industry standards:

- ISO 9001 for quality management systems

- IPC standards for PCB fabrication and assembly

- RoHS compliance for environmental regulations

- Industry-specific certifications such as AS9100 for aerospace applications

ISO9001 is a family of international quality management standards and guidelines aiming to promote global companies and organizations’ capabilities to meet and exceed the needs and expectations of customers.

Advanced Testing and Inspection

Modern turnkey facilities employ sophisticated testing methodologies to ensure product reliability:

Automated Optical Inspection (AOI): Real-time detection of assembly defects during production.

In-Circuit Testing (ICT): Verification of electrical functionality and component placement accuracy.

X-Ray Inspection: X-ray, functional circuit test, automatic optical inspection, flying probe test, thermal aging, tension test, peel-off test, salt spray test provide comprehensive validation of complex assemblies.

Functional Testing: Complete system validation to ensure products meet specified performance requirements.

Risk Mitigation Strategies

Turn-key PCB assembly also helps mitigate risk. Your partner assumes responsibility for any problems related to the assembly process, ensuring the finished product meets your specifications.

Turnkey providers offer several risk mitigation advantages:

Supply Chain Resilience: Diverse supplier networks and strategic inventory management reduce vulnerability to component shortages.

Quality Warranties: Comprehensive guarantees covering both materials and workmanship.

Process Documentation: Detailed records enabling rapid problem resolution and continuous improvement.

Regulatory Compliance: Expertise in navigating complex regulatory requirements across different markets.

Industry Applications: Versatility Across Sectors

Turnkey PCB assembly serves diverse industries, each with unique requirements and challenges that benefit from integrated manufacturing solutions.

Automotive Electronics

The automotive industry represents one of the fastest-growing sectors for PCB applications, driven by electrification, autonomous driving technologies, and advanced infotainment systems. For PCBs used for automotive, medical, aerospace, and military applications, the Kelvin four-terminal sensing is necessary.

Automotive applications require:

- Extreme reliability for safety-critical systems

- Wide temperature range operation for harsh environments

- Electromagnetic compatibility (EMC) for complex electronic ecosystems

- Long-term durability for extended vehicle lifespans

Industries such as aerospace, military, and automotive electronics place a premium on THT because of its inherent reliability.

Medical Device Manufacturing

Medical electronics demand the highest levels of quality, reliability, and regulatory compliance. Turnkey providers specializing in medical applications offer:

- FDA and ISO 13485 compliance for medical device regulations

- Biocompatibility testing for implantable devices

- Cleanroom assembly for sterile applications

- Comprehensive documentation for regulatory submissions

Aerospace and Defense

Foxtronics EMS serves industries such as aerospace, medical, industrial, and automotive. Our AS9100, ISO, and ITAR certifications ensure compliance with the highest quality and regulatory standards.

Aerospace and defense applications require:

- MIL-SPEC compliance for military standards

- High-reliability components for mission-critical applications

- Environmental testing for extreme operating conditions

- Security protocols for sensitive applications

Consumer Electronics

The consumer electronics market drives innovation in miniaturization, cost optimization, and rapid product cycles. Consumer Electronics: Sleek smartphones, tablets, and wearables rely on HDI for their compact yet powerful architecture.

Consumer electronics benefit from turnkey assembly through:

- Cost optimization for price-sensitive markets

- Rapid prototyping for fast product development cycles

- Miniaturization expertise for compact designs

- High-volume production capabilities

Industrial and IoT Applications

The proliferation of IoT devices, projected to grow from 12,393 million in 2023 to 25,150 million by 2027, underscores the increasing reliance on PCBs in diverse applications.

Industrial and IoT applications require:

- Wide operating temperature ranges

- Robust environmental protection

- Long-term reliability

- Cost-effective solutions for distributed deployments

Technology Trends Shaping the Future of Turnkey Assembly

The PCB assembly industry is experiencing rapid technological advancement that’s reshaping manufacturing capabilities and market opportunities.

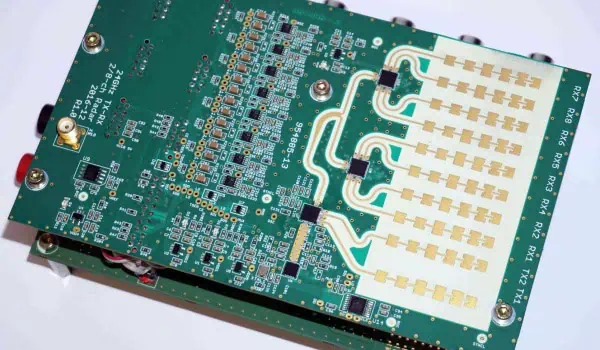

High-Density Interconnect (HDI) Technology

High-Density Interconnect (HDI) PCBs are redefining electronic design by enabling smaller, more powerful, and efficient devices. HDI technology offers several advantages:

- Reduced board size for compact applications

- Improved signal integrity for high-speed applications

- Enhanced electrical performance through shorter trace lengths

- Higher component density for increased functionality

According to a forecast, the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion.

Flexible and Rigid-Flex PCBs

The increased use of flexible PCBs is a driving factor behind the rapid growth in this market, especially for mobile devices like laptops, smartphones, and tablets.

Flexible PCB advantages include:

- Space conservation through three-dimensional assembly

- Reduced connector requirements for improved reliability

- Enhanced durability in dynamic applications

- Design flexibility for unique form factors

Sustainable Manufacturing Practices

Energy and water usage in the semiconductor industry are set to grow at a CAGR of 12% and 8% respectively from 2025-2035, with efficient management strategies for both critical.

Sustainability initiatives in PCB manufacturing include:

- Lead-free soldering processes for environmental compliance

- Recyclable substrate materials for end-of-life management

- Energy-efficient manufacturing to reduce carbon footprint

- Waste reduction programs for improved resource utilization

Artificial Intelligence and Automation

AI and IoT are not just application areas but also enablers in PCB manufacturing: Smart Manufacturing through AI-driven design optimization and error detection.

AI and automation applications include:

- Predictive quality control for defect prevention

- Automated design optimization for manufacturability

- Intelligent inventory management for supply chain efficiency

- Real-time process monitoring for continuous improvement

3D Printing and Additive Manufacturing

3D printing is transforming PCB production with benefits like faster turnaround times for designs, customization for tailored solutions, and cost efficiency by reducing material wastage.

3D printing applications in PCB manufacturing:

- Rapid prototyping for design validation

- Custom enclosures for integrated solutions

- Complex geometries for specialized applications

- Material innovation for enhanced performance

Selecting the Right Turnkey PCB Assembly Partner

Choosing the appropriate turnkey provider is crucial for realizing the full benefits of this manufacturing approach. Several key factors should guide this critical decision.

Technical Capabilities Assessment

Manufacturing Equipment: Evaluate the provider’s equipment capabilities, including pick-and-place machines, reflow ovens, inspection systems, and testing equipment. We use the latest MYDATA Pick & Place equipment, Glenbrook Technologies precision X-Ray imaging, and YESTech Optical Inspection units.

Component Handling: Assess capabilities for handling advanced package types, including fine-pitch components, BGAs, and ultra-small passive components.

Technology Roadmap: Ensure the provider invests in emerging technologies and maintains current with industry trends.

Quality Management Systems

Certifications: Verify appropriate industry certifications, including ISO 9001, IPC standards, and industry-specific requirements.

Quality Processes: Look into the provider’s track record in handling projects similar to yours. A company with extensive industry experience and proven technical capabilities is more likely to deliver consistent quality.

Traceability Systems: Ensure comprehensive component traceability and documentation systems for regulatory compliance and quality management.

Supply Chain Management

Supplier Network: Verify whether the provider has strong relationships with reliable component distributors. This ensures access to authentic parts, reduces the risk of counterfeits, and keeps lead times short.

Inventory Management: Evaluate inventory management systems and buffer stock capabilities for critical components.

Supply Chain Resilience: Assess strategies for managing supply chain disruptions and component obsolescence.

Engineering Support

Design for Manufacturing (DFM): Evaluate the provider’s DFM capabilities and experience in optimizing designs for cost and manufacturability.

New Product Introduction (NPI): Assess processes for transitioning from prototype to production, including validation procedures and scaling capabilities.

Technical Support: Reliable providers don’t just stop at delivery. Post-assembly support, including troubleshooting and warranty services, is a key factor for long-term cooperation.

Communication and Project Management

Responsiveness: Evaluate communication systems and response times for project updates and issue resolution.

Project Management: Assess project management capabilities, including milestone tracking, risk management, and change control processes.

Geographic Considerations: Consider location factors for communication, logistics, and supply chain optimization.

Implementation Best Practices

Successfully implementing turnkey PCB assembly requires careful planning and strategic execution to maximize benefits and minimize risks.

Preparation Phase

Requirements Definition: Clearly define technical specifications, quality requirements, regulatory compliance needs, and delivery expectations.

Design Documentation: Prepare comprehensive design documentation, including CAD files, BOMs, assembly drawings, and test specifications.

Risk Assessment: Identify potential risks and develop mitigation strategies for component availability, technical challenges, and schedule constraints.

Partner Evaluation and Selection

Request for Proposal (RFP): Develop comprehensive RFPs that clearly communicate requirements and evaluation criteria.

Capability Assessment: Conduct thorough evaluations of potential partners, including facility visits and reference checks.

Pilot Projects: Consider starting with smaller pilot projects to evaluate partnership effectiveness before committing to larger programs.

Ongoing Relationship Management

Performance Monitoring: Establish key performance indicators (KPIs) for quality, delivery, cost, and service levels.

Regular Reviews: Conduct periodic business reviews to assess performance, identify improvement opportunities, and address challenges.

Continuous Improvement: Collaborate on continuous improvement initiatives to optimize processes, reduce costs, and enhance quality.

Cost-Benefit Analysis: Quantifying the Turnkey Advantage

Understanding the financial impact of turnkey PCB assembly requires comprehensive analysis of both direct and indirect cost factors.

Direct Cost Comparison

Component Costs: Compare pricing between self-sourcing and turnkey provider rates, considering volume discounts and supplier relationships.

Assembly Costs: Evaluate assembly pricing, including labor, overhead, and margin components.

Logistics Costs: Factor in shipping, handling, and inventory carrying costs for different approaches.

Indirect Cost Considerations

Administrative Overhead: Calculate the cost of managing multiple supplier relationships, including procurement, quality assurance, and coordination activities.

Risk Costs: Assess potential costs associated with quality issues, delivery delays, and supply chain disruptions.

Opportunity Costs: Consider the value of internal resources that can be redirected to core business activities.

Total Cost of Ownership (TCO) Analysis

A comprehensive TCO analysis should include:

- Initial setup and qualification costs

- Ongoing operational costs

- Quality and warranty costs

- Flexibility and change management costs

- End-of-life and obsolescence costs

Future Outlook: The Evolution of Turnkey Assembly

The turnkey PCB assembly industry continues evolving, driven by technological advancement, market demands, and changing business models.

Market Growth Projections

The printed circuit boards (PCB) market is set to witness significant growth between 2025 and 2035, driven by increasing demand from the consumer electronics, automotive, healthcare, and telecommunications industries.

Growth drivers include:

- 5G and 6G technology deployment

- Electric vehicle adoption

- IoT and edge computing expansion

- Healthcare digitization

Technological Advancement

Manufacturing 4.0: Integration of AI, IoT, and advanced automation will continue transforming manufacturing capabilities.

Material Innovation: Development of new substrate materials, including biodegradable and recyclable options, will address sustainability requirements.

Process Innovation: Advanced manufacturing techniques, including additive manufacturing and selective processing, will enable new capabilities.

Supply Chain Evolution

Regionalization: Regionalization strategies will emerge as companies seek to establish localized production hubs to reduce supply chain risks and enhance sustainability.

Digital Integration: Enhanced digital integration will improve supply chain visibility, predictive analytics, and automated decision-making.

Sustainability Focus: Increased emphasis on sustainable practices will drive innovation in materials, processes, and lifecycle management.

Conclusion: Embracing the Turnkey Advantage

Turnkey PCB assembly represents more than just a manufacturing service—it’s a strategic enabler for electronics companies seeking competitive advantage in an increasingly complex and fast-paced market. The benefits of cost reduction, accelerated time-to-market, enhanced quality control, and risk mitigation make turnkey assembly an compelling choice for companies ranging from innovative startups to established enterprises.

The key to success lies in understanding your specific requirements, carefully evaluating potential partners, and implementing turnkey solutions strategically. Companies that embrace this approach position themselves to focus on their core competencies—innovation, market development, and customer relationships—while leveraging specialized manufacturing expertise to deliver superior products efficiently and cost-effectively.

As the electronics industry continues its rapid evolution, driven by emerging technologies and changing market dynamics, turnkey PCB assembly will play an increasingly important role in enabling companies to navigate complexity, manage risk, and capitalize on opportunities. The organizations that recognize and act on this potential will find themselves well-positioned for success in the dynamic electronics marketplace of 2025 and beyond.

By partnering with the right turnkey provider and implementing best practices, electronics companies can transform their manufacturing operations from a source of complexity and cost into a competitive advantage that drives growth, innovation, and market success. The future belongs to companies that can move quickly, operate efficiently, and deliver quality—exactly what turnkey PCB assembly makes possible.

For Customers:

- Provide complete documentation: Accurate Gerber files, detailed BOM, and assembly drawings

- Consider DFM early: Design for manufacturability from the start

- Plan for component availability: Consider lead times and potential obsolescence

- Establish clear specifications: Testing requirements, quality standards, and packaging needs

For Manufacturers:

- Maintain robust supply chains: Multiple supplier relationships and inventory management

- Invest in quality systems: Comprehensive testing and process controls

- Provide transparent communication: Regular updates and clear reporting

- Offer design support: DFM analysis and optimization recommendations

Common Challenges and Solutions in Turnkey PCB Assembly

Component Shortages

Challenge: Supply chain disruptions and component availability Solution: Proactive component sourcing, alternative part suggestions, and inventory management

Design Issues

Challenge: Manufacturability problems discovered during production Solution: Comprehensive DFM analysis and early design review process

Quality Concerns

Challenge: Ensuring consistent quality across production runs Solution: Robust quality systems, statistical process control, and comprehensive testing

Lead Time Pressures

Challenge: Meeting tight delivery schedules Solution: Parallel processing, inventory management, and optimized workflows

Future Trends in Turnkey PCB Assembly

Automation and AI

Automation and smarter designs are making electronics more efficient and reliable.

Sustainability Focus

- Lead-free assembly processes

- RoHS compliance

- Environmentally friendly materials

- Waste reduction initiatives

Miniaturization

Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs.

Getting Started with Turnkey PCB Assembly

Step 1: Prepare Your Documentation

- Complete Gerber files

- Detailed Bill of Materials (BOM)

- Assembly drawings

- Test specifications

Step 2: Request Quotes

- Contact multiple turnkey providers

- Compare capabilities and pricing

- Evaluate technical expertise

- Check references and certifications

Step 3: Start with Prototypes

- Begin with small quantities

- Validate the manufacturing process

- Test quality and performance

- Refine design if needed

Step 4: Scale to Production

- Transition from prototype to production

- Establish long-term partnerships

- Implement continuous improvement

- Monitor quality and delivery

FAQs:

Q: What’s the difference between turnkey and consignment assembly? A: In turnkey assembly, the manufacturer sources all components. In consignment assembly, you provide the components and the manufacturer handles assembly only.

Q: How long does turnkey PCB assembly take? A: Lead times typically range from 5-10 days for prototypes to 3-6 weeks for production volumes, depending on complexity and component availability.

Q: Can I supply some components for turnkey assembly? A: Yes, this is called partial turnkey assembly, where you provide specific components while the manufacturer sources the rest.

Q: What files do I need for turnkey PCB assembly? A: You’ll need Gerber files, drill files, Bill of Materials (BOM), assembly drawings, and test specifications.

Q: How do turnkey providers ensure component quality? A: RayMing source from authorized distributors, perform incoming inspection, and maintain traceability throughout the process.