Product Overview

Rogers CuClad laminates are advanced woven fiberglass/PTFE composite materials engineered for high-frequency printed circuit board substrates and radome applications. These microwave-grade laminates combine the superior electrical properties of polytetrafluoroethylene (PTFE) with the mechanical stability of woven fiberglass reinforcement, delivering exceptional performance for demanding RF and microwave applications.

Key Features

Superior Material Design

- Cross-plied woven fiberglass construction with alternating plies oriented 90° to each other

- High PTFE to glass ratio for optimal electrical performance

- Precision-controlled fiberglass/PTFE ratio enabling a range of dielectric constant options

- True electrical and mechanical isotropy in the X-Y plane – unique among PTFE-based laminates

Exceptional Electrical Performance

- Ultra-low dielectric constants ranging from 2.17 to 2.60

- Extremely low electrical loss with dissipation factors from 0.0009 to 0.0017 at X-band

- Superior dielectric constant uniformity compared to non-woven fiberglass reinforced laminates

- Stable performance across frequency range ensuring consistent signal integrity

Outstanding Thermal Properties

- Low moisture absorption (0.02-0.03%)

- Controlled thermal coefficient of dielectric constant

- Excellent thermal stability for high-temperature applications

- Low outgassing characteristics suitable for aerospace applications

Product Variants

CuClad 217 (εr = 2.17, 2.20)

- Lowest dielectric constant available in fiberglass-reinforced PTFE laminates

- Ultra-low dissipation factor of 0.0009 @ 10 GHz

- Fastest signal propagation with highest signal-to-noise ratios

- Optimal for ultra-high frequency applications requiring minimal signal loss

CuClad 233 (εr = 2.33)

- Balanced performance with medium fiberglass/PTFE ratio

- Improved dissipation factor of 0.0013 @ 10 GHz

- Enhanced mechanical properties without sacrificing electrical performance

- Ideal for applications requiring both low loss and mechanical stability

CuClad 250 (εr = 2.40-2.60)

- Superior mechanical properties approaching conventional substrates

- Enhanced dimensional stability with lower thermal expansion

- Dissipation factor of 0.0017 @ 10 GHz

- Perfect for applications demanding maximum mechanical reliability

Technical Specifications

| Property | CuClad 217 | CuClad 233 | CuClad 250 |

|---|---|---|---|

| Dielectric Constant @ 10 GHz | 2.17, 2.20 | 2.33 | 2.40-2.55 |

| Dissipation Factor @ 10 GHz | 0.0009 | 0.0013 | 0.0017 |

| Thermal Coefficient of εr (ppm/°C) | -160 | -161 | -153 |

| Water Absorption (%) | 0.02 | 0.02 | 0.03 |

| Peel Strength (lbs/inch) | 14 | 14 | 14 |

| Dielectric Breakdown (kV) | >45 | >45 | >45 |

| Flammability Rating | UL94-V0 | UL94-V0 | UL94-V0 |

Primary Applications

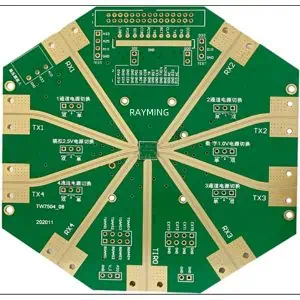

Military & Defense Electronics

- Radar systems (ECM, ESM)

- Electronic warfare equipment

- Avionics systems

- Communications, navigation, and identification (CNI) systems

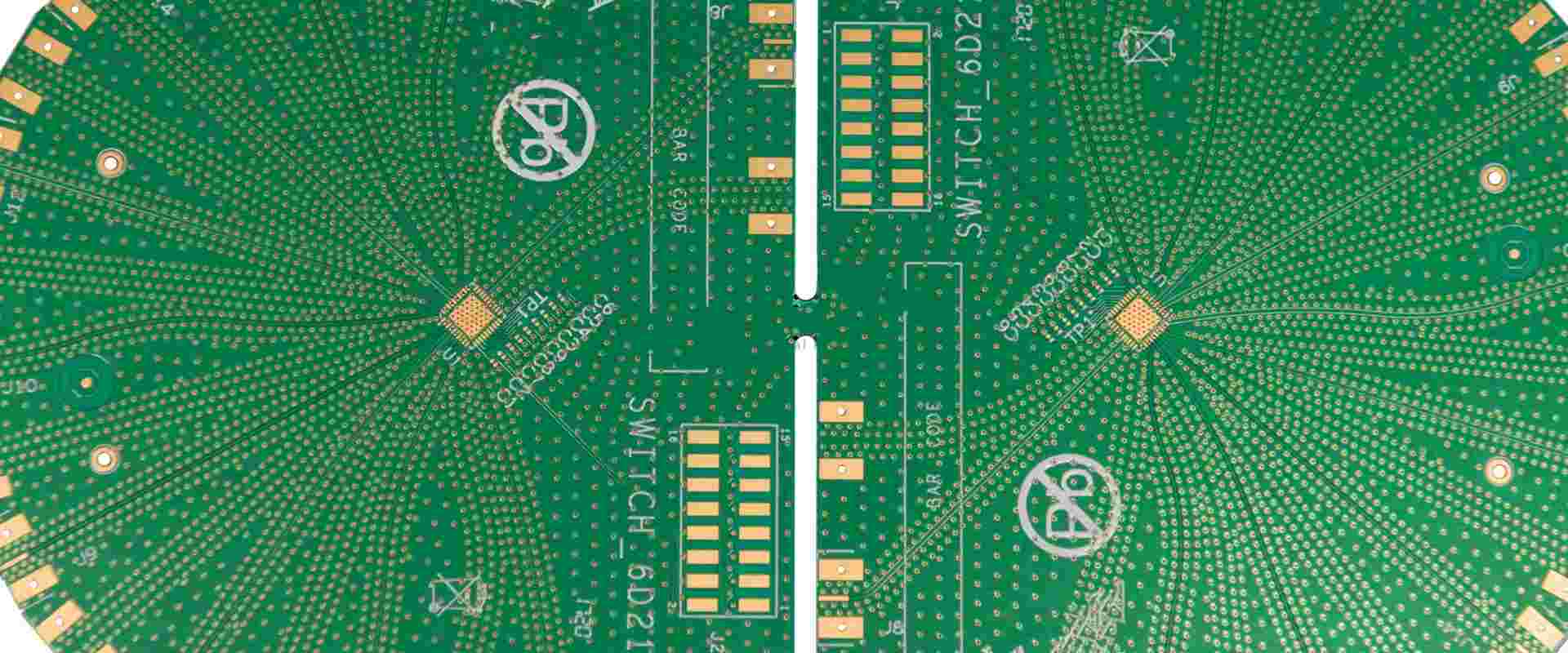

Commercial Microwave Components

- Low noise amplifiers (LNAs)

- RF filters and couplers

- Phase-sensitive filters

- Antenna systems and radomes

High-Frequency Communications

- 5G wireless infrastructure

- Automotive radar sensors (77 GHz)

- Satellite communication systems

- Millimeter-wave applications

Specialized Applications

- Phased array antennas requiring electrical isotropy

- Microstrip and stripline circuits

- High-reliability aerospace systems

- Ultra-low loss signal transmission systems

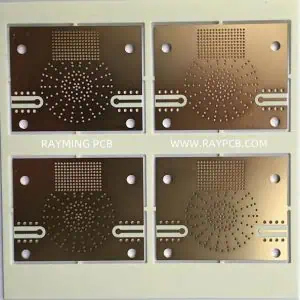

Material Availability & Options

Copper Cladding Options

- Standard: 1/2, 1, or 2 oz electrodeposited copper on both sides

- Custom: Other copper weights and rolled copper foil available

- Ground plane bonding available with aluminum, brass, or copper plates for heat sinking

Panel Sizes

- Cross-plied configuration: 36″ × 36″ master sheets

- Parallel-plied configuration: 36″ × 48″ master sheets

- Custom sizes available upon request

Quality Grades

- Standard grade for general applications

- “LX” testing grade for critical performance applications with individual sheet testing and certification

Benefits & Advantages

Performance Benefits

- Faster signal propagation due to low dielectric constants

- Reduced signal loss at high frequencies

- Enhanced signal-to-noise ratios for improved system performance

- Frequency-stable characteristics simplifying multi-band designs

Manufacturing Advantages

- Compatible with standard PCB processing techniques

- Excellent dimensional stability for high-yield manufacturing

- Reliable plated through-hole performance due to low thermal expansion

- Process chemical resistance ensuring fabrication reliability

Design Flexibility

- Range of dielectric constants for application-specific optimization

- True X-Y plane isotropy critical for phased array applications

- Consistent material properties enabling reliable multi-layer designs

- Proven reliability in demanding aerospace and military applications

Environmental & Safety Compliance

- RoHS compliant materials

- REACH regulation compliant with no SVHC substances

- UL94-V0 flammability rating for safety-critical applications

- Low outgassing meeting NASA space application requirements

- Halogen-free options available for environmentally sensitive applications

Rogers CuClad® laminates represent the industry standard for high-performance PTFE-based circuit materials, offering unmatched combination of electrical performance, mechanical reliability, and manufacturing consistency for the most demanding high-frequency applications.