What is Rogers Circuit Board Material?

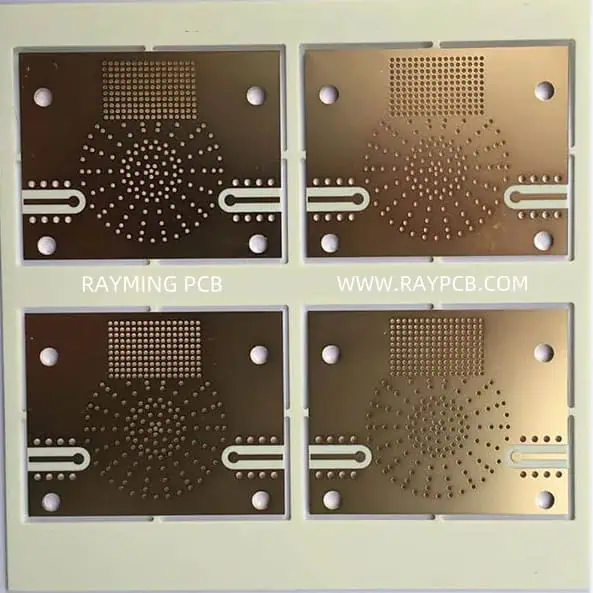

Rogers PCB is a type of high-performance printed circuit board substrate material that is made by laminating multiple layers of specialized materials together. The material is named after the Rogers Corporation, which is a leading manufacturer of high-performance engineered materials. These advanced materials have revolutionized high-frequency electronics by providing superior electrical and thermal properties compared to standard FR-4 substrates.

Key Characteristics and Properties

Superior Dielectric Performance

Rogers PCB materials have a low dielectric constant, typically between 2.2 and 3.5, which means that they can maintain signal integrity and minimize signal loss at high frequencies and over long distances. This low dielectric constant enables faster signal propagation and reduced interference, making Rogers materials ideal for high-speed digital circuits and wireless communication systems.

Exceptional Loss Tangent

Rogers PCB materials have a low loss tangent, typically between 0.001 and 0.002, which means that they can minimize signal attenuation and distortion. This property ensures excellent signal integrity even in demanding high-frequency applications.

Outstanding Thermal Stability

Standard FR4 boards have a Tg of 135C to 180C while Rogers 4350B and 4003C has a Tg >= 280C. This superior thermal performance makes Rogers materials suitable for high-power applications and extreme operating environments.

Popular Rogers PCB Material Series

RO4000 Series

Rogers RO4000 series: A high-frequency laminate material with low dielectric loss and low moisture absorption. The RO4000 series features hydrocarbon ceramic laminates that provide exceptional performance for microwave applications while being easier to fabricate than traditional PTFE materials.

RO3000 Series

Rogers RO3000 series: A high-frequency laminate material with low loss tangent and excellent dimensional stability. These ceramic-filled PTFE composites are widely used in RF and microwave applications, offering consistent electrical and mechanical properties across various dielectric constants.

RT/duroid Series

Rogers RT/duroid series: A high-frequency material with high thermal conductivity and low loss tangent. This series excels in applications requiring superior thermal management and ultra-low loss characteristics.

TMM Series

Rogers TMM series: A high-thermal conductivity material with low dielectric loss and high thermal stability. TMM materials combine ceramic, hydrocarbon, and thermosetting polymers for versatile high-performance applications.

Applications and Industries

Rogers circuit board materials find extensive use across multiple industries:

Aerospace and Defense: Circuit boards that are used in the avionics sector should be able to tolerate extreme temperature swings, shock, vibrations, and pressure changes. The excellent thermal properties of Rogers make them ideal for avionics equipment.

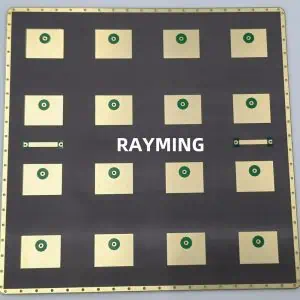

Telecommunications: High-frequency performance makes Rogers materials perfect for cellular base station antennas, power amplifiers, and 5G infrastructure.

Automotive: Modern radar systems and advanced driver assistance systems (ADAS) benefit from Rogers’ consistent performance and reliability.

Medical Electronics: Precision medical devices requiring stable performance in critical applications utilize Rogers materials for their reliability.

Cost Considerations and Value

The cost of Rogers PCB materials is typically higher than that of standard FR-4 materials, and the materials may require specialized processing techniques and equipment. However, for applications that demand high performance and reliability, Rogers PCB materials are often the substrate material of choice.

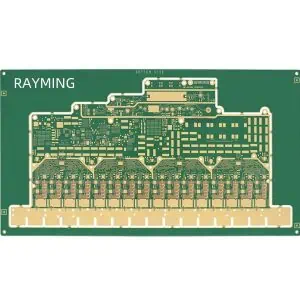

To optimize costs while maintaining performance, designers can employ hybrid constructions combining Rogers cores with FR-4 prepregs, use cost-effective Rogers variants like RO3003, and work with experienced manufacturers to streamline processing.

Manufacturing Compatibility

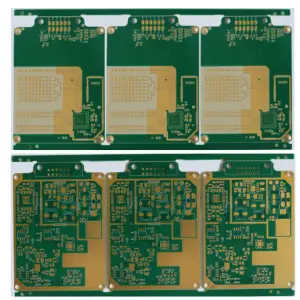

Rogers materials can be processed similarly to FR-4, ensuring straightforward integration into existing PCB manufacturing workflows. This compatibility reduces the learning curve and manufacturing complexity while delivering superior performance.

Rogers circuit board materials represent the pinnacle of high-frequency PCB technology, offering unmatched performance for applications where signal integrity, thermal management, and reliability are paramount. While the initial cost may be higher than conventional materials, the superior performance and reliability justify the investment for demanding applications.