High-Performance RF/Microwave PCB Laminate Material

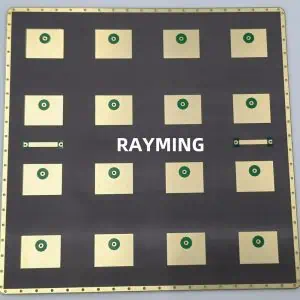

Rogers 4003C is a premium thermoset ceramic-filled hydrocarbon/ceramic laminate engineered specifically for high-frequency and microwave applications where precise dielectric constant control is critical.

Key Dielectric Properties

Dielectric Constant (Dk):

- Nominal value: 3.38 ± 0.05 at 10 GHz

- Recommended design value: 3.55

- Stable across frequency range from 1 GHz to 10 GHz

- Tight tolerance of ±0.05 ensures consistent impedance control

Loss Characteristics:

- Loss tangent: 0.0027 at 10 GHz

- Remains below 0.005 up to 3 GHz

- Approximately 0.0035 at 5 GHz

Material Construction & Performance

Rogers 4003C features proprietary woven glass reinforced hydrocarbon/ceramics that deliver the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. Available in both 1080 and 1674 glass fabric styles , all configurations meet identical electrical performance specifications.

Thermal Properties

- Thermal conductivity: 0.71 W/m/K in the z-axis

- Operating temperature: Continuous operation at 130°C with intermittent excursions to 150°C

- Coefficient of thermal expansion: 17 ppm/°C (X-Y), 32.5 ppm/°C (Z)

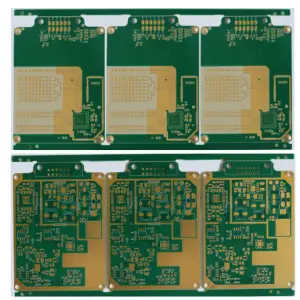

Manufacturing Advantages

- Utilizes standard epoxy/glass processing methods at a fraction of conventional microwave laminate costs

- No special through-hole treatments or handling procedures required

- Compatible with lead-free soldering processes up to 260°C

- Halogen-free composition for environmental compliance

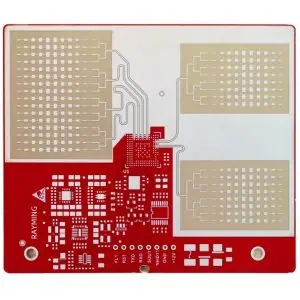

Applications

Ideal for controlled impedance RF circuits, microwave frequencies, wireless communications, RADAR systems, medical equipment, test equipment, antenna systems, and IoT applications operating up to 3 GHz and beyond.

The stable dielectric constant of Rogers 4003C enables precision impedance control essential for high-frequency circuit designs while maintaining cost-effectiveness and manufacturing compatibility with standard PCB processes.