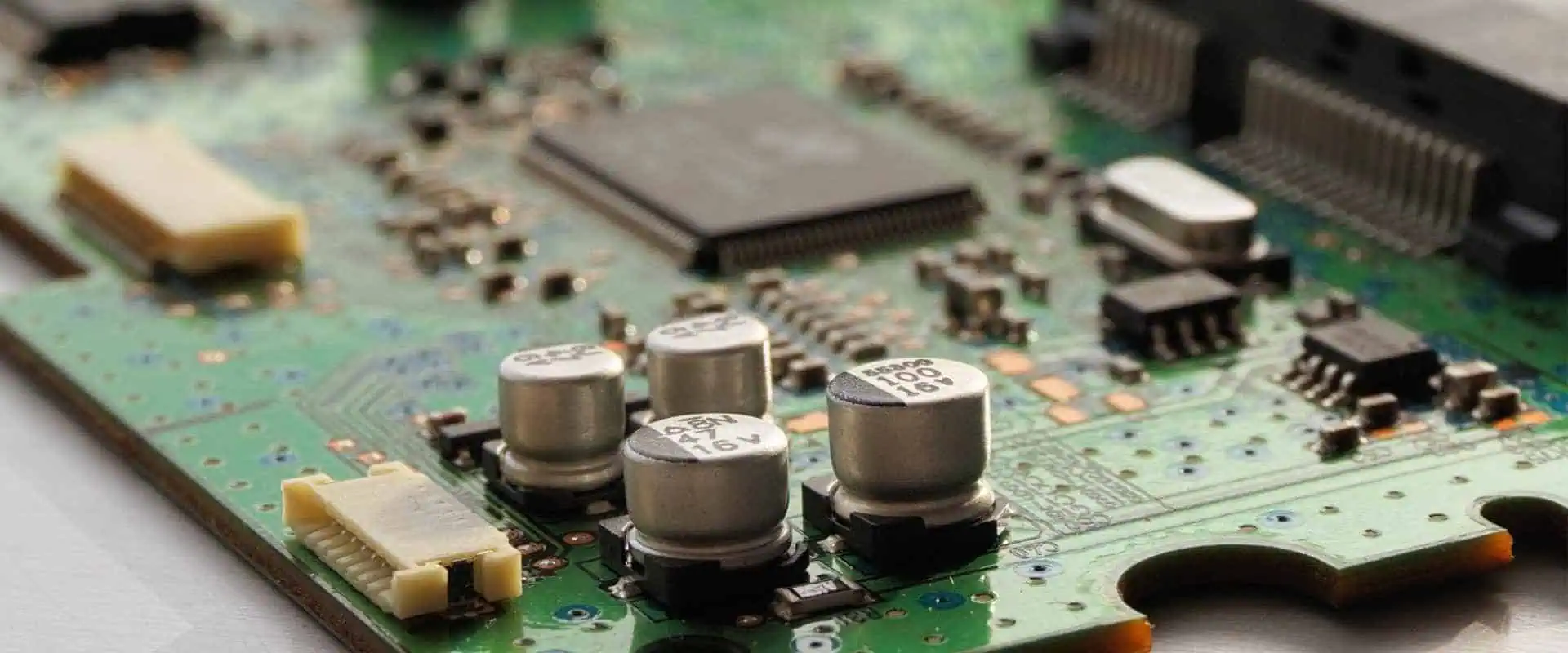

Transform your electronic designs into reality with our comprehensive PCB assembly services. We specialize in both surface mount technology (SMT) and through-hole assembly, delivering precision-manufactured circuit boards that meet the highest industry standards.

Surface Mount Technology (SMT) Assembly

Our state-of-the-art SMT assembly process handles components as small as 01005 packages with exceptional accuracy. Using advanced pick-and-place equipment and reflow ovens, we achieve consistent solder joint quality and optimal component placement. SMT assembly offers superior electrical performance, reduced electromagnetic interference, and enables compact, lightweight designs perfect for modern electronics.

Key capabilities include:

- High-speed automated placement of resistors, capacitors, ICs, and specialty components

- Fine-pitch BGA and QFN package assembly

- Double-sided SMT population

- Automated optical inspection (AOI) for quality assurance

Through-Hole Assembly

For applications requiring robust mechanical connections and high-power components, our through-hole assembly services provide the durability and reliability your products demand. Our skilled technicians utilize selective soldering and wave soldering techniques to ensure strong, consistent connections for connectors, transformers, and other through-hole components.

Services encompass:

- Manual and automated component insertion

- Wave soldering and selective soldering processes

- Mixed-technology boards combining SMT and through-hole

- Custom fixturing for specialized requirements

Quality and Testing

Every assembled PCB undergoes rigorous testing including in-circuit testing (ICT), functional testing, and visual inspection. We maintain ISO 9001 certification and IPC-A-610 compliance, ensuring your products meet aerospace, medical, automotive, and industrial quality standards.

Our assembly services support prototypes through high-volume production runs, with flexible scheduling and competitive pricing. From consumer electronics to mission-critical applications, we deliver the precision and reliability your projects require.