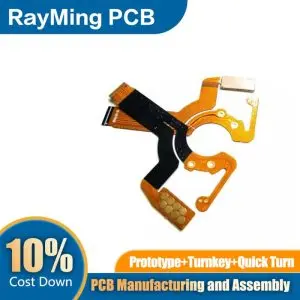

Our comprehensive flex circuit assembly services provide expert component mounting on flexible printed circuit boards, delivering reliable interconnect solutions for space-constrained and dynamic applications. We specialize in precisely placing and soldering components onto flexible substrates while maintaining the circuit’s bendability and mechanical integrity.

Service Capabilities

Component Mounting Expertise We handle a wide range of components including surface-mount devices (SMDs), fine-pitch connectors, flex-to-board connectors, and specialized flexible circuit components. Our technicians are skilled in working with the unique challenges of flexible substrates, ensuring proper adhesion and electrical connectivity without compromising flexibility.

Advanced Assembly Processes Our state-of-the-art facility utilizes specialized equipment designed for flexible circuit handling, including low-temperature soldering processes, precision placement systems, and controlled-pressure bonding techniques. We maintain strict temperature and handling protocols to prevent damage to sensitive flexible materials.

Quality & Reliability Every assembly undergoes rigorous testing including electrical continuity checks, bend testing, and visual inspection under magnification. We follow IPC standards specific to flexible circuits and maintain full traceability throughout the assembly process.

Applications

Ideal for aerospace, medical devices, automotive electronics, consumer electronics, and industrial equipment where space savings, weight reduction, and mechanical flexibility are critical. Our assemblies excel in applications requiring repeated flexing, 3D packaging, and complex routing geometries.

Key Benefits:

- Reduced assembly size and weight

- Enhanced reliability in dynamic applications

- Expert handling of sensitive flexible materials

- Complete testing and validation services

- Fast turnaround times with quality assurance

Trust our experienced team to deliver precision flex circuit assemblies that meet your most demanding performance requirements while maintaining the flexibility advantages that make these solutions indispensable in modern electronics.