Circuit Card Assembly (CCA) represents the backbone of modern electronics manufacturing, transforming bare printed circuit boards into functional electronic systems that power everything from smartphones to aerospace equipment. As technology continues to advance at an unprecedented pace, understanding the intricacies of circuit card assembly becomes increasingly critical for engineers, manufacturers, and businesses seeking to bring innovative products to market.

Understanding Circuit Card Assembly

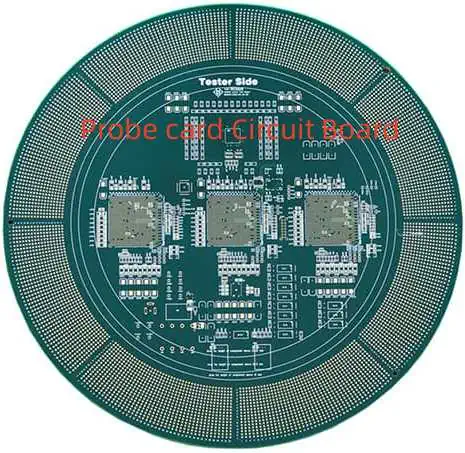

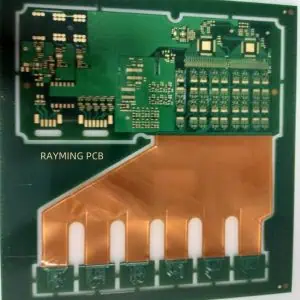

Circuit Card Assembly refers to the comprehensive process of mounting electronic components onto a printed circuit board (PCB) to create a functional electronic device. A circuit card can refer not only to the circuit board, but also to the circuit board that has been installed and assembled with electronic components. It contains a printed circuit board and all soldered components, such as resistors, capacitors, IC chips, etc. This transformation process converts a basic substrate into a sophisticated electronic system capable of performing complex operations.

The distinction between a circuit card and a circuit board is often misunderstood in the industry. A circuit board usually refers to the bare board that has not been assembled, without soldering any components. It is the basic part of the electronic system, mainly used in the design and development stage. Once components are assembled onto this bare board, it becomes a Circuit Card Assembly, also known as PCBA (Printed Circuit Board Assembly).

The Manufacturing Process: From Concept to Completion

The circuit card assembly manufacturing process is a meticulously orchestrated sequence of operations that demands precision, expertise, and advanced technology. Circuit card assembly or circuit card assembly manufacturing process is an intricate, accurate process. Transforming an empty card to a ready-to-use electronic component, each step matters, including solder paste application, component placement, reflow soldering and inspection and testing

Solder Paste Application

The journey begins with solder paste application, the foundation upon which all subsequent operations depend. The first step in the process of circuit card assembly manufacturing is the solder paste application, where steel is used to apply an even layer of solder paste to the associated solder pad on the circuit card. This critical step requires precise control of paste volume, consistency, and placement accuracy to ensure reliable electrical connections.

Modern manufacturing facilities utilize advanced stenciling equipment that can achieve placement accuracies within micrometers. The solder paste itself is a carefully formulated mixture combining solder particles with flux, designed to provide both mechanical stability and excellent electrical conductivity during the soldering process.

Component Placement Technology

Following solder paste application, the component placement phase represents one of the most technologically advanced aspects of circuit card assembly. The next step is placing components. This is the process of placing electronic components, including resistors, capacitors, and IC chips, on a circuit card that has been pre-treated with an appropriate amount of solder paste.

Contemporary placement machines can achieve speeds exceeding 100,000 components per hour while maintaining placement accuracies of ±25 micrometers. These sophisticated systems utilize computer vision technology, laser measurement systems, and advanced robotics to ensure precise component orientation and positioning. The integration of artificial intelligence and machine learning algorithms has further enhanced placement accuracy and reduced defect rates.

Reflow Soldering and Quality Control

The reflow soldering process transforms the temporarily placed components into permanent, reliable connections. This controlled heating process melts the solder paste, creating metallurgical bonds between components and PCB pads. Temperature profiles must be carefully managed to prevent component damage while ensuring complete solder joint formation.

Modern reflow ovens utilize multiple heating zones with precise temperature control, typically featuring convection heating systems that provide uniform heat distribution across the entire circuit card. Nitrogen atmosphere capabilities help prevent oxidation and improve solder joint quality, particularly important for lead-free soldering processes.

Industry Applications and Market Dynamics

Circuit card assembly manufacturers play an essential role in advancing technological capabilities across diverse industries. The applications span from consumer electronics to mission-critical aerospace systems, each demanding specific quality standards and manufacturing approaches.

Automotive Electronics

The automotive sector represents one of the fastest-growing markets for circuit card assembly. Modern vehicles contain dozens of electronic control units (ECUs) managing everything from engine performance to infotainment systems. These applications demand exceptional reliability, often requiring components to function flawlessly for decades under extreme temperature variations, vibrations, and electromagnetic interference.

Medical Device Manufacturing

Medical applications impose some of the most stringent requirements in circuit card assembly. Devices must meet FDA regulations, ISO 13485 standards, and often require biocompatibility certifications. The assembly process must maintain complete traceability from raw materials through final testing, ensuring patient safety and regulatory compliance.

Telecommunications Infrastructure

5G networks and advanced telecommunications equipment rely heavily on high-frequency circuit card assemblies. These applications demand exceptional signal integrity, minimal loss characteristics, and the ability to handle high-power RF signals without degradation.

Industrial and IoT Applications

The Industrial Internet of Things (IoT) has created unprecedented demand for compact, reliable circuit card assemblies capable of operating in harsh industrial environments. These devices must withstand temperature extremes, chemical exposure, and mechanical stress while maintaining consistent performance.

Advanced Manufacturing Technologies

Leading pcba companies are not only focused on scalability but also on introducing innovative technologies that enhance the quality and reliability of their assemblies The integration of Industry 4.0 principles has revolutionized circuit card assembly manufacturing, introducing smart factory concepts that optimize efficiency and quality.

Surface Mount Technology Evolution

Surface Mount Technology (SMT) continues to evolve, with component sizes decreasing while functionality increases. The latest 01005 components (0.4mm x 0.2mm) challenge traditional placement and inspection capabilities, requiring advanced equipment and processes. Fine-pitch ball grid arrays (BGAs) with pitch dimensions below 0.4mm demand sophisticated placement systems and X-ray inspection capabilities.

Through-Hole Technology Applications

While SMT dominates modern assembly, through-hole technology remains essential for high-power applications, connectors, and components requiring mechanical strength. Selective soldering systems have replaced traditional wave soldering for many applications, providing precise heating control and reducing thermal stress on sensitive components.

Advanced Inspection and Testing

Quality assurance has evolved beyond simple visual inspection to incorporate sophisticated automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT). These systems utilize artificial intelligence algorithms to identify defect patterns and continuously improve detection capabilities.

Supply Chain Management and Global Manufacturing

Furthermore, their commitment to rigorous quality standards and certifications not only boosts consumer confidence but also strengthens supply chain dynamics within the industry The global nature of electronics manufacturing presents both opportunities and challenges for circuit card assembly operations.

Component Sourcing Strategies

Effective component sourcing requires sophisticated supply chain management systems capable of tracking availability, pricing, and quality across multiple suppliers. The semiconductor shortage of 2020-2022 highlighted the importance of diversified sourcing strategies and the need for predictive analytics in supply chain management.

Geographic Manufacturing Considerations

Manufacturing location decisions involve complex trade-offs between labor costs, proximity to markets, supply chain efficiency, and regulatory requirements. Many companies employ a distributed manufacturing strategy, utilizing regional facilities to serve local markets while maintaining centralized engineering and quality control functions.

Quality Standards and Certifications

Our manufacturing processes adhere to the highest industry standards, validated by internationally recognized certifications including ISO 9001, ISO 13485, and IATF 16949 Quality management systems form the foundation of successful circuit card assembly operations.

IPC Standards Compliance

The IPC (Association Connecting Electronics Industries) standards provide comprehensive guidelines for circuit card assembly processes. IPC-A-610 defines acceptability criteria for electronic assemblies, while IPC-J-STD-001 covers soldering requirements. Compliance with these standards ensures consistent quality and reliability across different manufacturing facilities.

Environmental Compliance

We are equally committed to environmental responsibility, ensuring all products comply with RoHS and REACH regulations Environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) continue to shape manufacturing processes and material selection.

Future Trends and Technological Advancement

The circuit card assembly industry stands at the threshold of significant technological advancement. Emerging trends include the integration of embedded components, 3D printing of electronic circuits, and the development of flexible and stretchable electronics.

Artificial Intelligence Integration

AI-powered systems are increasingly being deployed for predictive maintenance, quality optimization, and process control. Machine learning algorithms analyze vast amounts of manufacturing data to identify patterns and optimize processes in real-time.

Sustainable Manufacturing Practices

Environmental sustainability has become a critical consideration in circuit card assembly manufacturing. This includes the development of lead-free soldering processes, reduction of volatile organic compounds (VOCs), and implementation of circular economy principles in electronics manufacturing.

Miniaturization and System Integration

The continued push toward miniaturization drives innovation in assembly techniques, requiring ever-more precise placement capabilities and innovative packaging solutions. System-in-Package (SiP) and 3D integration technologies are becoming increasingly important for space-constrained applications.

Conclusion

Circuit card assembly represents a critical intersection of engineering excellence, manufacturing precision, and technological innovation. As electronic systems become increasingly complex and demanding, the importance of sophisticated assembly processes and quality management systems continues to grow. By leveraging automation and adopting best practices, top players in the circuit card assembly market are positioning themselves at the forefront of technology, ready to meet future demand

Success in this industry requires a comprehensive understanding of manufacturing processes, quality standards, supply chain management, and emerging technologies. Organizations that invest in advanced manufacturing capabilities, maintain rigorous quality standards, and adapt to evolving market demands will continue to lead the transformation of ideas into reality through superior circuit card assembly solutions.

The future of electronics manufacturing depends on continued innovation in circuit card assembly processes, and companies that embrace these challenges while maintaining unwavering commitment to quality will shape the technological landscape of tomorrow.