Audio power amplifiers are essential components in sound reproduction systems, serving as the critical link between low-power audio signals and speakers. Their design and manufacturing involve sophisticated engineering principles across electronics, materials science, and acoustics.

Modern amplifier design begins with careful selection of circuit topology. Class A amplifiers deliver exceptional audio fidelity but operate inefficiently, continuously drawing power regardless of signal level. Class AB designs represent a popular compromise, offering good sound quality with reasonable efficiency. Class D amplifiers, using pulse-width modulation techniques, achieve remarkable efficiency exceeding 90% but require precise implementation to maintain audio quality.

The heart of any amplifier is its power supply. Linear power supplies employ transformers and rectifiers to convert AC to DC, offering low noise but significant weight. Switch-mode power supplies operate at high frequencies, providing efficiency and compactness at the cost of potential noise issues requiring careful filtering and shielding.

Component selection critically impacts performance. High-quality capacitors with low equivalent series resistance (ESR) ensure stable power delivery under dynamic conditions. Premium resistors with tight tolerances maintain channel balance and reduce thermal noise. Output transistors must handle peak current demands while operating within safe thermal limits, necessitating proper heat sink design.

Feedback systems play a crucial role in controlling distortion. Negative feedback reduces distortion but must be implemented carefully to avoid oscillation or phase issues that compromise sound quality. Some audiophile designs employ minimal feedback philosophies, placing greater emphasis on inherent circuit linearity.

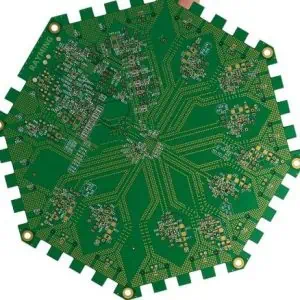

The printed circuit board (PCB) layout is more critical than many realize. Ground plane design, trace width for power-carrying conductors, and component placement all affect performance. Engineers must consider thermal management, electromagnetic interference, and signal integrity in their layouts.

Manufacturing processes have evolved significantly. Modern facilities employ surface-mount technology (SMT) for most components, with automated pick-and-place machines ensuring precise positioning. Selective soldering techniques handle through-hole components while maintaining production efficiency.

Quality control involves multiple inspection points. Automated optical inspection (AOI) systems verify component placement and soldering quality. Functional testing includes power output verification, distortion measurements, frequency response analysis, and thermal cycling to identify potential reliability issues.

The final amplifier enclosure serves both aesthetic and functional purposes. Beyond visual appeal, it must provide adequate ventilation while protecting internal components from dust and interference. Premium manufacturers often employ extruded aluminum chassis for superior heat dissipation and electromagnetic shielding.

Market segmentation has created diverse manufacturing approaches. Mass-market manufacturers focus on cost optimization through integrated circuits and automated assembly. High-end boutique manufacturers often emphasize hand-selected components, point-to-point wiring, and extensive burn-in testing.

Emerging technologies continue to reshape amplifier design. GaN (Gallium Nitride) and SiC (Silicon Carbide) semiconductors enable higher switching frequencies and improved efficiency in Class D designs. Advanced DSP (Digital Signal Processing) integration allows for room correction, crossover management, and other sophisticated features previously requiring separate components.

The amplifier market spans from affordable consumer products to esoteric high-end designs costing tens of thousands of dollars. Despite this range, all share the fundamental challenge of faithfully reproducing audio signals without coloration while delivering sufficient power to drive connected speakers effectively.