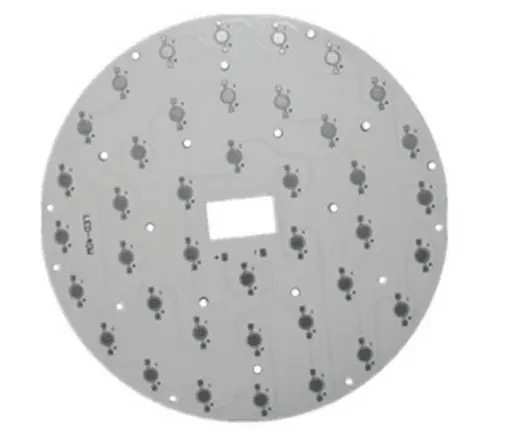

Our Aluminum Core PCB (MCPCB) substrate delivers superior thermal management for high-power electronic applications. Engineered with a precision aluminum base layer, this substrate efficiently dissipates heat while maintaining excellent electrical insulation properties.

Key Features:

- Exceptional Heat Dissipation: Aluminum core provides 5-8x better thermal conductivity than standard FR4 substrates

- Reliable Electrical Isolation: High-performance dielectric layer ensures safe electrical separation between circuits and aluminum base

- Enhanced Component Lifespan: Effective heat removal reduces thermal stress on LEDs, power transistors, and other heat-sensitive components

- Lightweight Design: Aluminum construction offers excellent strength-to-weight ratio compared to ceramic alternatives

Technical Specifications:

- Thermal conductivity: 1.0-3.0 W/mK (dielectric layer)

- Base material: High-purity aluminum alloy

- Dielectric breakdown voltage: >3000V

- Operating temperature range: -40°C to +150°C

- Available thicknesses: 0.8mm to 3.2mm

Applications:

- High-power LED lighting systems

- Automotive electronics and lighting

- Power converters and inverters

- RF and microwave amplifiers

- Solar panel junction boxes

- Industrial motor drives

Benefits: This substrate solution enables designers to achieve higher power densities while maintaining reliability. The aluminum core acts as both a heat spreader and mechanical support, eliminating the need for additional heat sinks in many applications. Compatible with standard PCB manufacturing processes, it offers a cost-effective thermal management solution for demanding electronic systems.

Ideal for applications requiring efficient heat dissipation, electrical isolation, and mechanical durability in a single substrate solution.