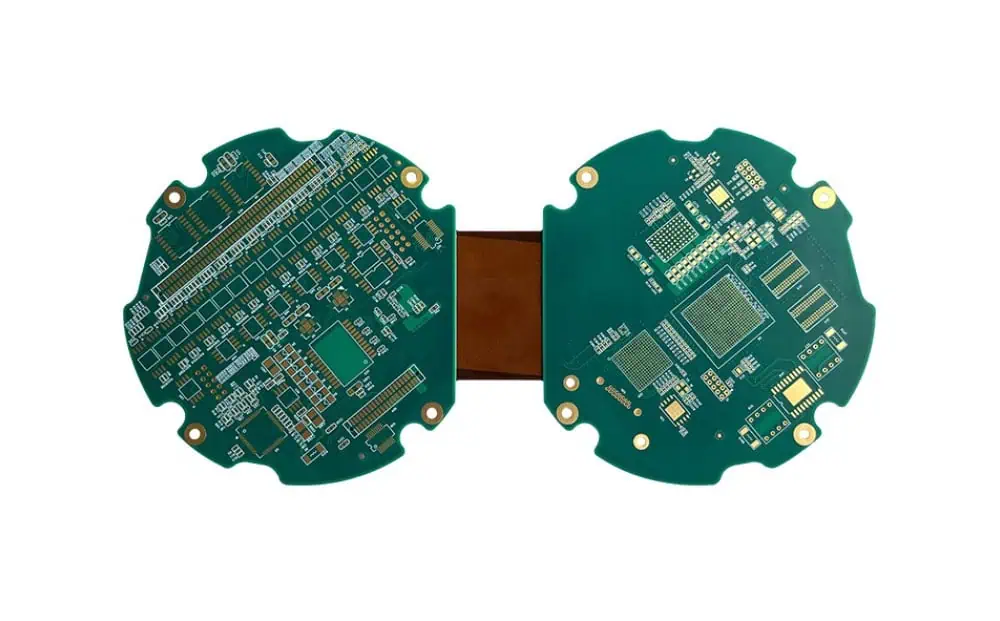

Professional Multi-Layer PCB Solutions for Advanced Electronic Applications

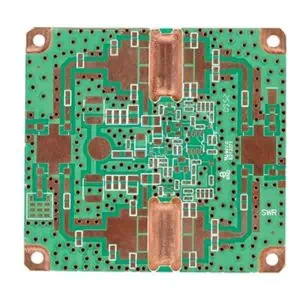

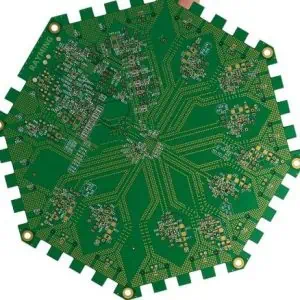

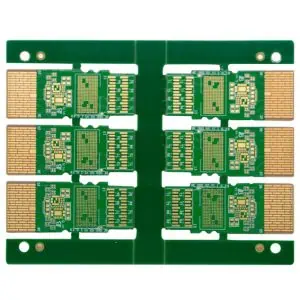

Our 16-layer PCB manufacturing service delivers precision-engineered high-density boards designed for complex electronic systems requiring superior performance and reliability. These advanced multi-layer printed circuit boards provide exceptional signal integrity, power distribution, and component density capabilities for demanding applications.

Key Features:

- 16 copper layers with optimized stack-up configurations

- High-density interconnect (HDI) technology supporting fine-pitch components

- Advanced via structures including blind, buried, and micro vias

- Controlled impedance matching for high-speed digital signals

- Tight tolerance manufacturing with ±0.1mm precision

- Multiple surface finishes including HASL, ENIG, and OSP

- Comprehensive testing including electrical, mechanical, and visual inspection

Technical Capabilities:

- Minimum trace width: 0.075mm (3 mil)

- Minimum via size: 0.1mm (4 mil)

- Layer thickness control: ±10%

- Impedance tolerance: ±5%

- Board thickness: 0.8mm to 6.0mm

- Maximum board size: 610mm x 457mm

Applications: Perfect for telecommunications equipment, aerospace systems, medical devices, high-performance computing, automotive electronics, and industrial control systems where space optimization and signal integrity are critical.

Quality Assurance: Manufactured to IPC-A-600 Class 2/3 standards with full traceability, AOI inspection, and comprehensive electrical testing. ISO 9001 certified facility ensures consistent quality and reliability.

Lead Time: 10-15 business days for standard specifications, with expedited options available for urgent projects.

Contact us for custom stack-up design consultation and competitive pricing for your high-density PCB requirements.