Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper PCB pads. However, leftover flux residues can cause issues like electrical leakage, dendrites, corrosion or failures under humidity if not properly cleaned post-soldering.

This article provides a comprehensive guide to managing flux residues including:

- The flux cleaning imperative

- Water and solvent-based cleaning approaches

- Process considerations and challenges

- Cleanliness validation methods

- FAQs related to post-solder flux removal

Learning flux residue removal best practices helps improve electronics assembly yields, reliability and long term functionality.

The Critical Need to Remove Flux

While flux residues seem innocuous, they can severely impact PCB performance and lifespan if left on assemblies after soldering.

Some potential reliability risks posed by ionic flux residues like weak organic acids or halides include:

Electrical leakage – Absorbs moisture and creates current leakage paths

Corrosion – Gradually corrodes copper traces or component leads

Dendrites – Grows conductive metallic crystals eventually causing shorts

Insulation resistance degradation – Allows resistive power losses through surface films

Cosmetic issues – Causes surface discoloration or tacky coatings

So removing flux after soldering is an indispensable process step to ensure lasting PCB integrity.

Next let’s contrast cleaning approaches using solvents versus aqueous methods.

Solvent Cleaning Agents Used

Solvent cleaning refers to using organic chemical solutions to dissolve then rinse away flux residues. Some typcal solvents include:

Isopropyl alcohol (IPA) – Rapidly evaporates with wide materials compatibility

Acetone – Stronger solvency but more aggressive requiring dilution

Terpenes – Plant derived citrus cleaners with reduced environmental impact

Solvent cleaning can be performed by manual wiping, immersion tanks, inline conveyors and ultrasonic or pressure spray systems with vacuum drying.

Some benefits of solvent cleaning include:

- Removes diverse flux chemistries like rosin mildly, no-clean, water soluble types

- Penetrates tight gaps under components to access hidden residues

- Quickly dissolves both ionic and non-ionic contamination

- Enables isolated spot cleaning of small areas when needed

- Wide availability of chemical compatibility data to guide material selections

However, solvents also pose flammability, waste disposal and regulatory emission control challenges. This motivates aqueous process alternatives.

Aqueous Flux Residue Cleaning Processes

Water-based cleaning relies on ionized water’s natural solvency power combined with detergents at elevated temperatures and impingement pressures to reliably remove residues.

Some common aqueous cleaning systems include:

Immersion washers – Features multiple staged baths for gross soil removal down to rinses

Inline washers – Continuous conveyors passing boards through spray detergent zones + rinses

Ultrasonic systems – Energized baths generating focused cavitation shockwaves hitting board surfaces

Pressure spray washers – Direct high impingement jets + mechanical scrubbing on boards

Condensation washers – Controlled condensing humidity enclosures to lift residues

Water cleaning is attractive because it avoids hazardous chemical disposal requirements and utilizes lower cost aqueous detergents. Thermal energy efficiently substitutes harsh solvents.

Key benefits of aqueous cleaning encompass:

- Eco/worker friendly with simpler waste water treatment

- Readily accessible and plentiful water media

- Heated spray and ultrasonics provide excellent cleaning power

- Programmable automation adaptable for high volume applications

- Reliable reproducibility following validated cycles

On the downside, aqueous processes lack penetration into tight spaces. Water sensitivity limits components exposure allowances too. Despite such constraints, appropriate water-based cleaning systems prove highly effective for suitable PCB assembly applications when engineered properly.

Now that we distinguished solvent versus water-based options, let’s elaborate best practice process considerations to deploy either approach effectively.

Optimizing Process Parameters for Flux Removal Efficiency

Successfully removing flux residues depends greatly on selecting optimal equipment settings and following disciplined operating protocols tailored to your boards.

Here are some key process parameters to optimize:

Cleaning Media – Match solvent or water-based detergent chemistry to flux type and processing goals. Start with manufacturers recommended formulations.

Concentration – For aqueous cleaners, calibrate detergent % dilution carefully for target soils. Excessive concentrations waste chemicals whereas low concentrations risk cleaning shortfalls.

Exposure Time – Ensure adequate dwell time for cleaning agents to penetrate, solubilize and detach all residues present. Complex boards need longer durations.

Temperature – Heated media between 50-80°C boosts cleaning dynamics substantially compared to room temperatures for dried residues. But don’t overheat beyond chemical or component limits.

Flow Rate (solvent) – Adjust solvent spray flow to flood boards without excessive impingement pressure causing component blow-off defects.

Impingement Pressure (aqueous) – Steam and spray jets help blast off hardened residues mechanically when delicately optimized in psi/bar units without deforming boards.

Frequency – Replenish baths regularly based on accumulated soil loading quantified in microSiemens to maintain cleaning efficiency as contaminants saturate solutions.

Careful process testing starting from baseline presets then gradually adjusting within equipment safe ranges determines optimums empirically case-by-case based on cleaner qualifications.

Next we’ll highlight some practical challenges working with either cleaning technique.

Comparison of Solvent vs Aqueous Challenges

While both solvent and water cleaning methods scrub residues when done properly, each encounters characteristic implementation difficulties in applications:

Solvent Cleaning Challenges

- Flammability risks requiring costly special equipment and safety procedures

- Hazardous waste disposal, emissions regulations and records compliance

- Component or housing damage from aggressive solvents like acetone

- Manual cleaning consistency challenges at high production volumes

- Residue re-deposition drying stains if not handled properly

Aqueous Cleaning Challenges

- Prolonged water exposure degrades moisture sensitive components

- Reaches under tight component gap limitations

- Mixed material compatibility constraints like magnesium or glass restrictions

- Tank maintenance and microbiological contaminant risks

- Stains or white water marks if inadequately rinsed and dried

Accounting for these unique constraints guides appropriate water or solvent-based flux residue cleaning selection for targeted assembly needs.

Finally, validating cleaning effectiveness proves highly beneficial.

Techniques to Verify Adequate Flux Residue Removal

While visual inspection checks for noticeable surface residue left on PCBs post-cleaning, several quantitative techniques reliably validate cleaning performance:

Ion Chromatography Analysis – Detects microscopic inorganic anion/cation content extracted from cleaned boards correlating well with residual ionic contamination. Parts per million sensitivity ensures boards are chemically clean.

Combustion Infrared Detection – Burns-off traces organics present then analyzes retained carbon content accurately determining any organic residues down to low PPm levels.

Oddy Test – Exposes cleaned coupons to active and blank copper strips in humidity and heat to check for dendrite growth assessing residue corrosivity tendency.

Surface Insulation Resistance – Measures electrical resistance across comb pattern test cards before and after cleaning, looking for order of magnitude reductions indicating surface contamination removal.

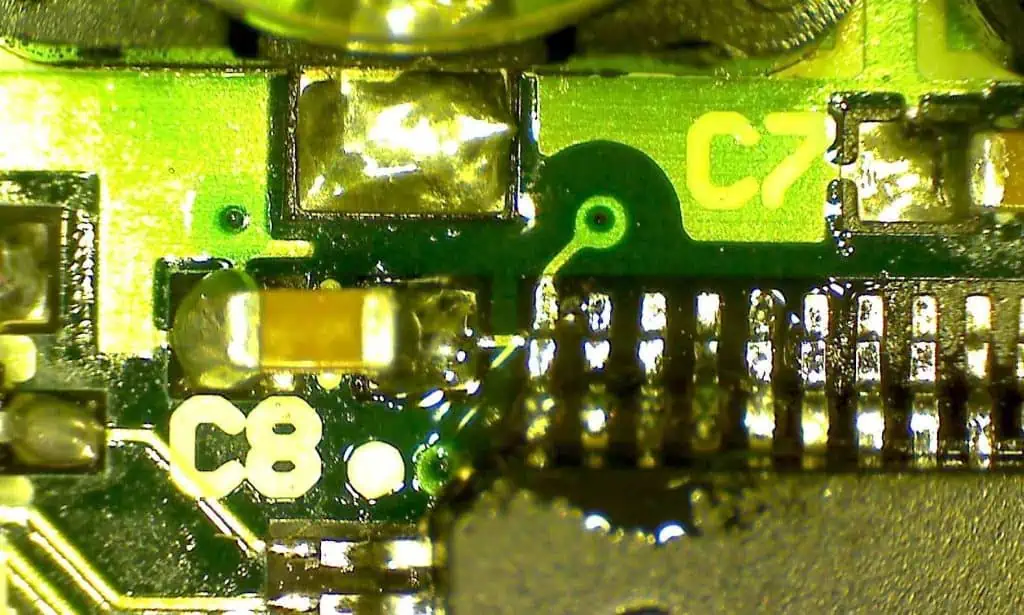

SEM Inspection – Scans high magnification SEM imaging across board surfaces confirming the complete absences of flux film or residues within equipment detection limits.

While adding test time and costs upfront, validating flux removal quality provides confidence regarding long term reliability over product lifespan for critical applications.

With key flux cleaning concepts covered, we’ll wrap up by addressing common FAQs on the topic.

Frequently Asked Flux Residue Cleaning Questions

How do you know a PCB needs cleaning after hand soldering?

Visually inspect boards after hand soldering using bright side lighting at an angle to reveal residue films. Target hard to reach areas underneath component overhangs using an angled mirror. If hazy residue shows and especially if it feels tacky when touched, cleaning proves necessary to avoid electrical or corrosion issues long term.

What PCB cleaning methods work for large production volumes cost effectively?

For production environments producing hundreds or more boards daily needing cleaning, engineered inline aqueous cleaning systems provide the most cost effective, reproducible and automated process capabilities. These machines reliably meet high output needs while minimizing labor compared to batch processes.

How do ultrasonic and spray washers compare for removing baked-on flux?

While ultrasonic cavitation helps lift some thick flux layers, directly aiming high pressure or temperature sprays >80°C at the afflicted areas for extended intervals works best for stubborn baked residues. Precision wand attachments target cleaning streams. The combined chemical and mechanical attack focus breaks down the hardened layers efficiently.

Why does water temperature matter so much when cleaning flux residues?

Heating water to 50-60°C significantly accelerates flux dissolution kinetics following Arrhenius rate equations regarding reaction speeds exponentially improving with temperature. So rather than solely relying on detergent chemistry, harnessing thermal activation proves highly beneficial by preventing temperature limitations slowing cleaning.

How do you apply solvents for cleaning limited area touch-ups?

For isolated rework spots needing touch-up cleaning, precision cleaning pens flooding just the desired area with pressurized sprays of solvent work well. IPA, acetone and terpene pens confinement localizes application preventing widespread residues. Manual wiping then absorbs dissolved flux away.

Conclusion

In summary, allowing flux residues to remain on populated PCBs poses major reliability risks from electrical leaks, corrosion, dendrites and insulative surface films during operation. Assemblies therefore require proper validation of residue removal after soldering using metrics like ionic contamination, SIR comb testing or microscopy inspection.

Solvent and aqueous cleaning agents prove highly effective for dissolving and detaching flux films when judiciously matched to process needs based on considerations like media temperature, concentration, exposure interval and impingement pressure optimization. Accounting for flammability hazards, waste handling, material compatibility and drying defects guides proper implementation.

By mastering PCB flux residue removal techniques, engineers safeguard electronics functionality and longevity over targeted product lifetimes in the field. This best practice empowers quality outcomes and avoids premature operational failures related to post-soldering residues.