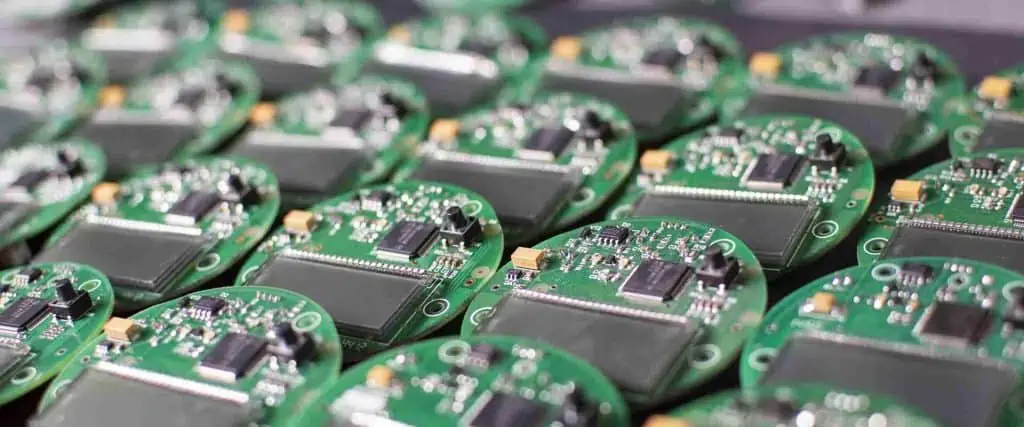

EMS PCBA, which is also described as the EMS PCB assembly, comes with many applications and advantages within different technology fields. This EMS denotes electronic manufacturing solutions or services, while PCBA denotes the assembly of printed circuit boards. Careful planning as well as being attentive to detail is very necessary in placing and spacing of the components, sizes of the hole and location, spacing of the component lead, components selection, as well as other considerations regarding the layout of the printed circuit board.

The EMS PCBA process deals with manufacturing many complex components and might be composed of different services like component procurement, engineering design, fabricating and assembling the PCB, functional testing, and box builds.

When handling product builds, the appropriate EMS PCBA execution reduces the whole time for manufacturing for that product, reduces the cost, and also increases the performance. You can attain a fast turnaround but this might vary depending on the PCB’s complexity as well as the availability of the electronic components.

What are the Applications of EMS PCBA?

EMS PCBA is applicable to different technologies as well as different industries. Practically every product containing electronic components will be able to benefit from EMS PCBA.

EMS PCBA is also applicable to different consumer electronics like CD players, alarm clocks having AM and FM radios, digital watches, microwave ovens, home theaters, cell phones, video games (hand held), toys (remote control type), etc.

Electronics and instrumentation for different industrial applications also make use of PCB EMS, which include weather radar and telemetry, strain gauges, network analyzers, spectrum analyzers, temperature gauges, ohm meters, environmental ovens and chambers, switcher power supply, oscilloscopes, CCD telescopes, and temperature meters. Other EMS PCBA applications include products used in many industries like medical, automotive, aerospace, and military.

What You Should Prepare For as EMS PCBA Manufacturers?

In order to have the EMS PCBA produced from a 3rd party manufacturer excluding any back and forth, you have to get these materials ready to get your quote.

Bill of Material (BOM): The BOM can be described as the component list containing all information regarding electronic components for the EMS PCBA assembly. These include the quantity, component reference, part number, footprint, name of manufacturer, etc.

Gerber: This is automatically generated from the software for PCB design after you much have completed the design. It is a compressed file containing the gerber file and drill file folders. Also, in this gerber folder, every PCB layer (circuit layer, silkscreen, substrate, and circuit layer) corresponds with a specific graphic file.

BOM and Gerber are very important materials needed from you to be delivered to the EMS PCBA manufacturer. When you provide this, the manufacturer will be able to conduct the EMS PCBA manufacturing.

3D drawing: This reveals the 3 dimensional outlooks of estimated PCB assemblies.

Assembly drawing: This reveals the estimated PCB assemblies

Pick and Place file: This lists the components’ reference on the board, making sure that your EMS manufacturer will be able to draw comparisons with the real PCBA. In fact, the EMS manufacturer of your choice can also generate this file.

What is the Process of EMS PCBA?

Application of the solder paste

After fabricating the bare PCB, pads won’t have a solder mask on them for the SMT. Throughout this process, the application of solder paste will then be done on the pads before making the components to sit on them. This paste is made up of 0.5% copper, 3% silver, and 96.5% tin. Later on, they will facilitate the electrical and physical connections present between the components/devices as well as the board.

Pick-and-place

Once you are done applying the solder paste, the printed circuit board will go to the pick and place machine. The SMDs can be placed on the board very quickly with the help of a robotic device. They are usually pre programmed for every project to help them know the exact location for the components.

Today, components are becoming smaller. The pick and place machine would have the capacity even on the least size of components that they can pick. However, if you have too small components, you may need to use a special machine to handle the process.

The Reflow Soldering

Immediately the SMDs and solder pastes are in place, then the next step is the process of reflow soldering. As the solidification of the paste takes place, these SMDs are tightly held onto the board.

You can achieve the reflow soldering process in reflow ovens using different heaters that gradually heats the board to a temperature of 250 degrees Celsius. At this stage, the solder paste has been melted properly. After this, this PCB keeps moving through the oven then gradually cools down. This paste is then cooled and then solidified.

Quality Control and Inspection

Immediately you are done with the surface mount process, an inspection will be conducted. This examines the electrical and physical connections present between the board and the devices. Solder joints that are bad usually cause serious problems with quality.

AOI is known as a well-known form of inspection for the large PCBA batches. The AOI machine features different cameras that aid the examination of these PCBs. These cameras are also arranged at varying angles to help view the solder connections.

Functional Testing and Final Inspection

After the PTH components and SMDs are placed, there’s a final inspection, which tests the functionality of the PCB. This PCB will undergo a simulation test. Simulated and power signals would run through the circuit board so that the electrical characteristics of the PCB are shown whenever the circuit board runs in usual circumstances.

EMS PCBA Manufacturing

Printed circuit board design

‘When designing the PCB, you’ll draw the schematics, deign the layer number, size, and stack up, and then set the rule of the routing width, fanout control rule, routing layers rule, rules for routing via style, and rules relating to electrical clearance You will have to work with some design rules.

These include placing the main and big components first and at the center surrounding them with the small components. You should also fanout the main and big components first. Another rule here is to separate the digital and analog signals.

PCB Assembly

Theoretically, the circuit board design is feasible only in theory. However in fabrication, even the small details which weren’t considered can fail your product. Before the batch EMS PCBA manufacturing, the manufacturer would first have to prototype.

PCBA Post-Assembly Stage

Some manufacturers of EMS PCBA offer the following value added services.

Conformal coating: Conformal coating can be applied on the PCBAs to be able to offer better protection as well as extend the electrical and electronic products’ lifespan.

IC programming: There are standard jigs for IC programming and the program can be transferred ontp the circuit board’s integrated circuit freely. Moreover, you have to provide this program. Also, if you wouldn’t want the EMS PCBA manufacturer to gain access and download the program, you can decide to give them the cloud interface. This allows the controlling and monitoring of all the programs transferred from the cloud into the IC.

Thermal aging testing: This allows the PCB to be powered on for at least 48 hours to ensure that the electrical products function properly for long periods.

Box-built assembly: This helps in designing your mechanical box in line with the requirements as well as having them produced by Shenzhen’s local factories. Later, these PCBAs are assembled with the mechanical boxes that correspond. Finally, a testing is conducted on a finished product to ensure that the box build is functioning normally. These manufacturers will then package them and ship them to you.

Choosing the Best EMS PCBA Manufacturer for You

Choosing the best manufacturer is important for the electronic product’s success. Let’s consider some important factors you should work with.

Experience

When selecting any manufacturer, make sure you work with one having vast experience instead of a novice. Working with a company that has experience in a similar project will be great. They will match your project needs better.

Quality

Quality has to be your priority when choosing an EMS PCBA manufacturer. Work with a manufacturer having strict quality controls. This is because substandard products may run your business and reputation.

Cost

When choosing a manufacturer, cost is another significant factor. Though it could be tempting to work with a manufacturer offering the lowest rate, you have to look at5 the future costs of choosing a manufacturer which offer low-quality products.

Compliance

Choosing a manufacturer that conforms to the relevant standard and rules of the industry regarding compliance is important. This is very important especially when that product is subjected to some regulatory requirements.

Capacity of Production

Your manufacturer must have enough manufacturing capacity of meeting your needs, most especially high-volume projects. Their capability will tell if they will deliver your product early.

Conclusion

The process of EMS PCBA manufacturing could be hassle-free, safe, quick, and easy. This article has been able to reveal how to have the EMS PCBA produced saving energy and time.

‘