In the ever-evolving world of electronics manufacturing and repair, Ball Grid Array (BGA) components have become increasingly common. These complex components require specialized equipment for installation and removal, making BGA rework stations an essential tool for professionals in the field. This article will delve into the key differences between infrared and hot air BGA rework stations, helping you make an informed decision when choosing the right equipment for your needs.

Understanding BGA Rework Stations

Before we dive into the comparison between infrared and hot air technologies, let’s first understand what a BGA rework station is and why it’s crucial in electronics repair and manufacturing.

What is a BGA Rework Station?

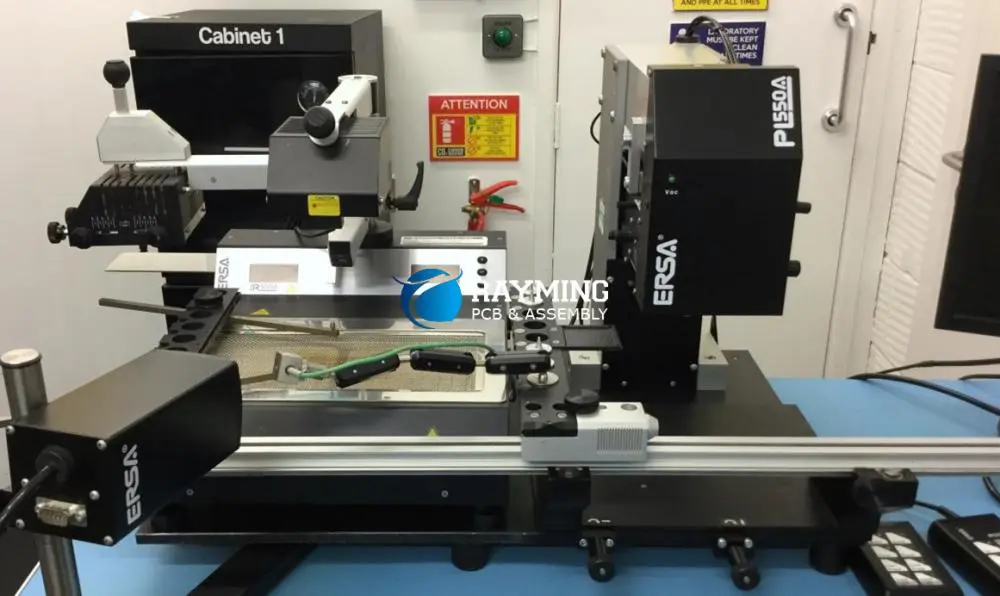

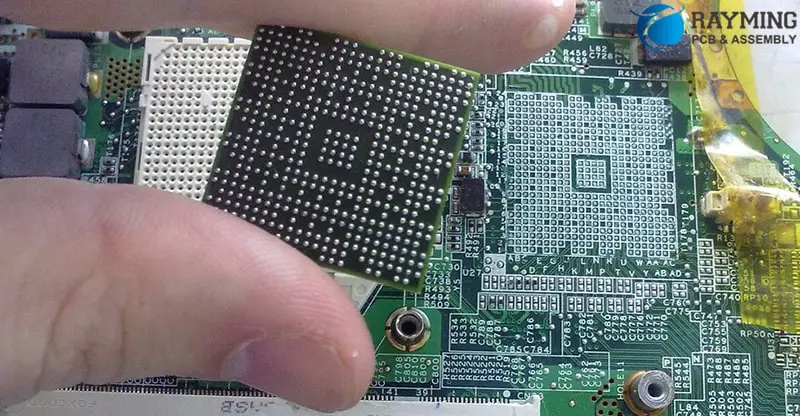

A BGA rework station is a specialized piece of equipment designed for the removal, replacement, and reworking of Ball Grid Array components on printed circuit boards (PCBs). These stations provide precise control over temperature, airflow, and other parameters to ensure safe and effective BGA rework operations.

The Importance of BGA Rework Stations

BGA components are widely used in modern electronics due to their high pin count and compact size. However, their complexity makes them challenging to repair or replace without specialized equipment. BGA rework stations offer the following benefits:

- Precision: They provide accurate temperature control and heat distribution.

- Safety: They minimize the risk of damage to the PCB and surrounding components.

- Efficiency: They streamline the rework process, saving time and resources.

- Versatility: They can handle a wide range of BGA package sizes and types.

Infrared BGA Rework Stations: An In-depth Look

Infrared BGA rework stations use infrared radiation to heat and remove BGA components. Let’s explore the technology behind these stations and their advantages and disadvantages.

How Infrared BGA Rework Stations Work

Infrared rework stations emit infrared radiation, which is absorbed by the BGA component and the PCB. This radiation heats the solder balls, causing them to melt and allowing for the removal or replacement of the BGA component.

Advantages of Infrared BGA Rework Stations

- Precise heating: Infrared technology allows for focused heating on specific areas.

- Consistent results: The heating process is highly repeatable, ensuring consistent outcomes.

- Less airflow: Reduced air movement minimizes the risk of component shifting.

- Suitable for lead-free solders: Infrared stations can achieve the higher temperatures required for lead-free solders.

Disadvantages of Infrared BGA Rework Stations

- Higher initial cost: Infrared stations are generally more expensive than hot air alternatives.

- Learning curve: Operators may require more training to use infrared stations effectively.

- Limited flexibility: Some infrared stations may struggle with non-standard PCB layouts.

Hot Air BGA Rework Stations: A Comprehensive Overview

Hot air BGA rework stations use convection heating to remove and replace BGA components. Let’s examine this technology and its pros and cons.

How Hot Air BGA Rework Stations Function

Hot air rework stations use a stream of heated air to melt the solder balls on BGA components. The hot air is directed onto the component and surrounding area, allowing for the removal or installation of the BGA chip.

Advantages of Hot Air BGA Rework Stations

- Cost-effective: Generally more affordable than infrared stations.

- Versatile: Can handle a wide range of component sizes and PCB layouts.

- Easy to use: Simpler operation makes them accessible to less experienced technicians.

- Faster heating: Hot air can quickly heat large areas of the PCB.

Disadvantages of Hot Air BGA Rework Stations

- Less precise: Heat distribution may be less focused compared to infrared technology.

- Risk of component shifting: The airflow can potentially move small components.

- Inconsistent results: Variations in airflow and heat distribution may lead to less repeatable outcomes.

Read more about:

Key Differences: Infrared vs. Hot Air BGA Rework Stations

Now that we’ve explored both technologies, let’s directly compare infrared and hot air BGA rework stations across several key factors.

1. Heat Distribution

- Infrared: Offers more focused and precise heat distribution, ideal for working on densely populated PCBs.

- Hot Air: Provides broader heat distribution, which can be advantageous for larger components but may affect surrounding areas.

2. Temperature Control

- Infrared: Generally offers more accurate temperature control, crucial for working with temperature-sensitive components.

- Hot Air: Temperature control can be less precise due to variations in airflow and environmental factors.

3. Component Compatibility

- Infrared: Excels with standard BGA components but may struggle with odd-shaped or reflective surfaces.

- Hot Air: More versatile in handling various component shapes and sizes.

4. Learning Curve and Ease of Use

- Infrared: Typically requires more training and experience to operate effectively.

- Hot Air: Generally easier to use, making it more accessible for beginners and small operations.

5. Cost Considerations

- Infrared: Higher initial investment but may offer long-term benefits in precision and consistency.

- Hot Air: More budget-friendly, making it a popular choice for smaller shops or hobbyists.

6. Speed of Operation

- Infrared: May require more time for setup and calibration but can offer faster rework times for complex operations.

- Hot Air: Quick setup and operation, but may need multiple passes for challenging rework tasks.

7. Solder Joint Quality

- Infrared: Often produces higher quality, more consistent solder joints due to precise heat control.

- Hot Air: Can achieve good results but may be more operator-dependent.

Choosing the Right BGA Rework Station for Your Needs

Selecting the appropriate BGA rework station depends on various factors specific to your requirements. Consider the following aspects when making your decision:

- Budget constraints

- Types of components you typically work with

- Volume of rework operations

- Skill level of operators

- Space limitations in your workspace

- Specific industry requirements or standards

Top Picks: Infrared BGA Rework Stations

Let’s explore some of the leading infrared BGA rework stations available in the market:

1. JOVY Systems RE-8500

The JOVY Systems RE-8500 is a high-end infrared rework station known for its precision and versatility.

Key features:

- Dual-zone heating system

- Large 5″ color touch screen

- Automatic profiling and temperature control

- Compatible with a wide range of BGA sizes

2. PDR IR-E3 Evolution Series

The PDR IR-E3 is a professional-grade infrared rework station offering advanced features for demanding applications.

Key features:

- Focused IR technology for precise heating

- Non-contact temperature sensing

- Automated profiling system

- Suitable for lead-free and leaded processes

3. Metcal BGA Rework System

Metcal’s BGA rework system combines infrared technology with advanced controls for reliable performance.

Key features:

- Closed-loop temperature control

- Programmable profiles for repeatable results

- Split vision system for accurate alignment

- Integrated cooling system

Top Picks: Hot Air BGA Rework Stations

Now, let’s look at some of the best hot air BGA rework stations on the market:

1. Hakko FR-810B

The Hakko FR-810B is a popular choice for its balance of performance and affordability.

Key features:

- Digital temperature and airflow control

- Nozzle-to-component distance sensor

- ESD-safe design

- Wide range of compatible nozzles

2. Quick 861DW

The Quick 861DW is a versatile hot air rework station suitable for various BGA rework tasks.

Key features:

- Brushless fan for stable airflow

- Large LCD display

- Sleep mode for energy saving

- Compatible with lead-free soldering

3. Aoyue Int968A+

The Aoyue Int968A+ is an all-in-one rework station that includes hot air, soldering iron, and smoke absorber functions.

Key features:

- Dual LED displays for temperature and airflow

- Built-in soldering iron with temperature control

- Integrated smoke absorber

- Wide range of temperature settings

Maintenance and Care for BGA Rework Stations

Proper maintenance is crucial for ensuring the longevity and performance of your BGA rework station. Here are some essential tips:

- Regular cleaning: Keep the station and nozzles clean to prevent buildup and ensure optimal performance.

- Calibration: Periodically calibrate temperature settings to maintain accuracy.

- Nozzle inspection: Check nozzles for wear or damage and replace as needed.

- Filter replacement: For hot air stations, replace air filters regularly to maintain proper airflow.

- Software updates: Keep the station’s software up to date for the latest features and improvements.

Safety Considerations When Using BGA Rework Stations

Safety should always be a top priority when working with BGA rework stations. Consider the following precautions:

- Proper ventilation: Ensure adequate ventilation to remove fumes and protect operators.

- Personal protective equipment: Use appropriate PPE, including heat-resistant gloves and safety glasses.

- ESD protection: Implement proper ESD safeguards to protect sensitive components.

- Training: Provide thorough training for all operators on safe equipment use and procedures.

- Emergency procedures: Establish and communicate clear emergency protocols.

Future Trends in BGA Rework Technology

As technology continues to advance, we can expect to see several developments in BGA rework stations:

- Increased automation: More automated features to reduce operator dependency and improve consistency.

- Enhanced precision: Advancements in temperature control and heat distribution for even more precise rework.

- Integration with other technologies: Combination of different heating methods for optimal results.

- Improved user interfaces: More intuitive controls and better data visualization for easier operation.

- Eco-friendly solutions: Development of more energy-efficient and environmentally friendly rework stations.

Conclusion: Making the Right Choice for Your BGA Rework Needs

Choosing between infrared and hot air BGA rework stations depends on your specific requirements, budget, and technical expertise. Infrared stations offer superior precision and consistency but come at a higher cost and with a steeper learning curve. Hot air stations provide versatility and ease of use at a more affordable price point but may sacrifice some precision.

Consider your typical workload, the components you regularly handle, and your team’s skill level when making your decision. Both technologies have their place in the world of electronics repair and manufacturing, and the right choice will depend on your unique circumstances.

Whichever technology you choose, investing in a quality BGA rework station will undoubtedly improve your ability to handle complex PCB repairs and replacements, keeping you competitive in the fast-paced world of electronics.