Hot swap PCBs have revolutionized the mechanical keyboard enthusiast community, offering unprecedented flexibility and customization options. Whether you’re a seasoned keyboard builder or just starting your mechanical keyboard journey, understanding hot swap PCBs is essential for making informed decisions about your setup.

What is a Hot Swap PCB?

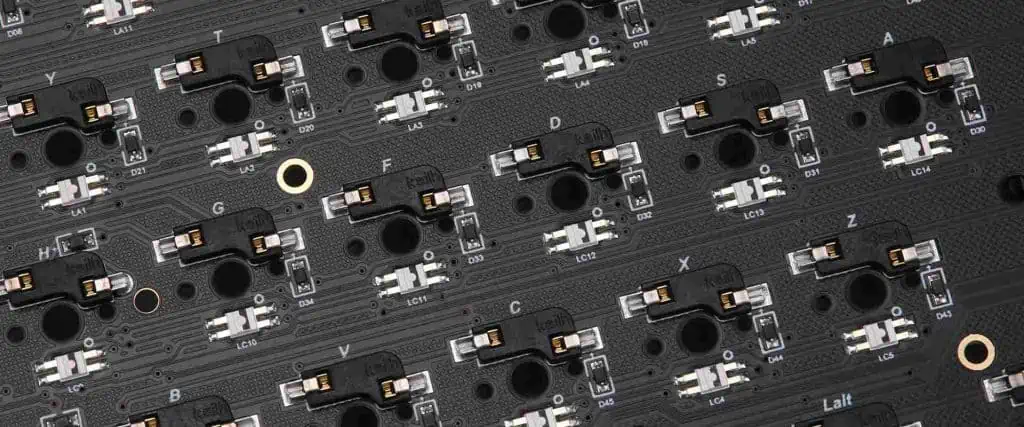

A hot swap PCB is a printed circuit board designed for mechanical keyboards that allows users to remove and install switches without soldering. Unlike traditional PCBs that require desoldering and resoldering switches for replacement, hot swap PCBs feature special sockets that securely hold switches while enabling tool-free removal.

This innovative design eliminates the need for soldering equipment and technical expertise, making keyboard customization accessible to everyone. The term “hot swap” refers to the ability to change components while the device remains powered and functional, though it’s recommended to disconnect your keyboard before switching components for safety.

Hot swap PCBs typically use specialized sockets like Kailh hot swap sockets, Mill-Max sockets, or proprietary designs from various manufacturers. These sockets create reliable electrical connections while maintaining the mechanical stability needed for consistent typing performance.

How Hot Swap PCBs Work

The Socket System

Hot swap PCBs utilize precision-engineered sockets that grip switch pins securely. When you insert a switch, the pins slide into the socket and make contact with internal spring-loaded connectors. This creates both electrical continuity and mechanical retention without permanent attachment methods.

The socket design varies between manufacturers, but most follow similar principles. Kailh hot swap sockets, for example, feature a plastic housing with metal contacts that compress around switch pins. This compression provides both electrical connection and physical retention, ensuring switches stay in place during normal use.

Compatibility Considerations

Most hot swap PCBs support standard MX-style switches, which include popular brands like Cherry MX, Gateron, Kailh, and many others. The standardized pin layout and spacing ensure broad compatibility across switch manufacturers.

However, some specialty switches may require specific socket types. Low-profile switches, optical switches, or switches with non-standard pin configurations may need dedicated hot swap solutions. Always verify switch compatibility before purchasing.

Types of Hot Swap PCBs

Kailh Hot Swap PCBs

Kailh hot swap sockets are among the most popular choices in the market. These purple-colored sockets offer excellent reliability and support virtually all MX-style switches. They’re rated for thousands of insertion cycles and provide consistent electrical performance.

Kailh sockets come in different variants, including standard sockets for through-hole mounting and low-profile versions for compact builds. Their widespread adoption means excellent availability and competitive pricing.

Mill-Max Hot Swap PCBs

Mill-Max sockets represent a premium hot swap solution often used in custom keyboards. These gold-plated sockets offer superior electrical performance and durability compared to plastic alternatives. They’re particularly popular among enthusiasts who prioritize long-term reliability.

Mill-Max sockets require more precise installation but provide a more refined typing experience. They’re available in various pin diameters to accommodate different switch types and mounting preferences.

Proprietary Hot Swap Systems

Many keyboard manufacturers develop their own hot swap solutions. Companies like Glorious, Drop, and Keychron have created proprietary socket designs optimized for their specific products. While these may offer unique advantages, they can limit switch compatibility or replacement options.

Benefits of Hot Swap PCBs

Easy Switch Customization

The primary advantage of hot swap PCBs is simplified switch replacement. You can experiment with different switch types, weights, and characteristics without commitment. This flexibility is invaluable for finding your perfect typing feel or accommodating different use cases.

Switch testing becomes practical and affordable when you can easily swap between options. Many enthusiasts maintain collections of different switches for various applications, from gaming to typing to programming.

No Soldering Required

Hot swap PCBs eliminate soldering barriers that prevent many people from customizing their keyboards. Traditional keyboard modification requires soldering skills, specialized equipment, and significant time investment. Hot swap systems make customization accessible to anyone comfortable with basic assembly.

This accessibility has dramatically expanded the mechanical keyboard community, allowing more people to explore customization without technical expertise or expensive tools.

Reduced Risk and Cost

Soldering carries inherent risks of component damage, PCB destruction, or personal injury. Hot swap PCBs eliminate these concerns while reducing the overall cost of experimentation. You can try expensive switches without permanent commitment or risk damaging your keyboard.

The ability to reuse switches across different builds also provides economic benefits. Premium switches represent significant investments that can be preserved and transferred between projects.

Faster Assembly and Modification

Hot swap assembly is significantly faster than traditional soldering. Complete keyboard builds that might take hours with soldering can be completed in minutes with hot swap PCBs. This speed advantage is particularly valuable for commercial applications or frequent modifications.

Limitations of Hot Swap PCBs

Socket Durability Concerns

While hot swap sockets are designed for repeated use, they have finite lifespans. Frequent switching can eventually wear out socket contacts or loosen retention mechanisms. Quality varies between manufacturers, with some sockets lasting thousands of cycles while others may fail prematurely.

Proper insertion and removal techniques can extend socket life, but eventual replacement may be necessary for heavily used keyboards.

Compatibility Restrictions

Hot swap PCBs typically support only specific switch types. Most accommodate standard MX-style switches, but specialty options like Alps, Topre, or custom switches may be incompatible. This limitation can restrict customization options compared to universal soldered solutions.

Potential Connection Issues

Socket connections may occasionally become unreliable, leading to intermittent key failures or inconsistent performance. These issues are relatively rare with quality sockets but more common with budget alternatives or heavily worn components.

Regular maintenance and careful handling can minimize connection problems, but they remain a consideration for critical applications.

Higher Initial Cost

Hot swap PCBs often cost more than traditional alternatives due to socket manufacturing costs and lower production volumes. This premium can be significant for budget-conscious builders, though the long-term value proposition may justify the investment.

Choosing the Right Hot Swap PCB

Layout Considerations

Hot swap PCBs are available in various layouts, from compact 60% designs to full-size options. Consider your space requirements, preferred key layout, and intended use case when selecting a size. Popular options include 65%, 75%, and TKL layouts that balance functionality with desk space efficiency.

Ensure your chosen layout includes all necessary keys for your workflow. Programmable PCBs offer additional flexibility through custom key mapping and macro functionality.

Build Quality and Brand Reputation

Research manufacturer reputation and user reviews before purchasing. Established brands like Keychron, GMMK, and Drop typically offer reliable products with good customer support. Unknown manufacturers may provide lower prices but potentially inferior quality or limited warranty coverage.

Pay attention to PCB thickness, component quality, and overall construction standards. Well-built PCBs provide better typing experiences and longer service life.

Feature Requirements

Consider additional features like RGB lighting, rotary encoders, USB-C connectivity, or wireless capability. These features can enhance your keyboard experience but may increase cost and complexity.

Programmability is particularly valuable for customization enthusiasts. QMK and VIA compatible PCBs offer extensive customization options for advanced users.

Installation and Maintenance Tips

Proper Switch Installation

Always align switch pins carefully before insertion to avoid socket damage. Bent pins can destroy sockets or create unreliable connections. Use gentle, even pressure when inserting switches, and ensure they’re fully seated before testing.

Some switches may require slight wiggling during insertion, but excessive force indicates potential problems. Remove and inspect both switch and socket if installation feels difficult.

Socket Maintenance

Periodically inspect sockets for wear, damage, or debris accumulation. Clean sockets gently with compressed air or soft brushes to remove dust and particles. Avoid liquid cleaners that might damage socket materials or electrical contacts.

Replace worn or damaged sockets promptly to prevent connection issues or further damage. Some sockets can be replaced individually, while others may require PCB replacement.

Switch Removal Techniques

Use proper switch pullers or improvised tools to remove switches safely. Avoid pulling on switch housings or using excessive force that might damage sockets. Some switches may require gentle rocking motions during removal.

Store removed switches in protective containers to prevent pin damage or debris contamination. Organize switches by type or characteristics for easy identification during future builds.

Popular Hot Swap PCB Options

Several manufacturers offer excellent hot swap PCB solutions for different needs and budgets. Keychron Q-series keyboards provide premium hot swap experiences with gasket mounting and extensive customization options. The GMMK Pro offers excellent value with solid construction and broad compatibility.

For budget-conscious builders, options like the Keychron K series or various Chinese manufacturers provide acceptable performance at lower price points. Custom PCB designers like AI03 and Gondolindrim create specialized solutions for enthusiast builds.

Consider your specific requirements, budget constraints, and long-term goals when selecting a hot swap PCB. The mechanical keyboard community offers extensive resources and reviews to help guide your decision.

Conclusion

Hot swap PCBs have transformed mechanical keyboard customization by eliminating technical barriers and reducing modification costs. While they have some limitations compared to traditional soldered solutions, the benefits typically outweigh the drawbacks for most users.

Whether you’re building your first custom keyboard or expanding an existing collection, hot swap PCBs offer unmatched flexibility and convenience. As the technology continues improving and costs decrease, hot swap systems are becoming the standard for enthusiast keyboards.

The future of mechanical keyboards lies in accessible customization, and hot swap PCBs represent a crucial step toward that goal. By understanding their capabilities and limitations, you can make informed decisions that enhance your typing experience while providing room for future experimentation and growth.