Input Parameters

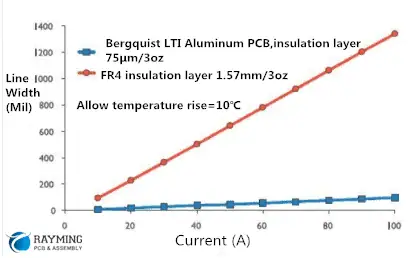

PCB Parameters

Set to 0 for natural convection from aluminum base

Design is Thermally Safe

25.0°C margin below max junction temp

Junction Temperature

60.0°C

Max Safe Power

15.0W

Thermal Resistance Breakdown

Thermal Path Visualization