Rogers RO4450T Bonding Film is a high-performance, 3.2-3.3 dielectric constant (Dk), low-loss, spread glass reinforced, ceramic-filled bonding material specifically designed to complement RO4835T laminates and the existing RO4000 laminate family for multilayer board construction. This advanced prepreg material provides exceptional design flexibility with multiple thickness options ranging from 2.5 to 6.0 mils.

Key Features and Benefits

Electrical Performance:

- Dielectric constant ranges from 3.19 to 3.35 across different thicknesses

- Low dissipation factor from 0.0033 to 0.0044

- Excellent dielectric constant control for repeatable electrical performance

- High frequency performance suitable for microwave and millimeter wave applications

Thermal Characteristics:

- Low z-axis coefficient of thermal expansion ranging from 43 to 60 ppm/°C

- Glass transition temperature (Tg) ranging from 176°C to 188°C

- Decomposition temperature (Td) of approximately 397-408°C

- UL 94 V-0 flame retardant rating

Processing Advantages:

- Compatible with standard epoxy/glass (FR-4) processes

- Sequential lamination capable – fully cured RO4000 products can withstand multiple lamination cycles

- Lead-free solder processing compatible

- Suitable for UV and CO2 laser processing for micro-blind holes and through holes

Available Configurations

Standard Thicknesses: Available in 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, and 6.0 mil thicknesses with ±0.0006″ tolerance

Panel Sizes: Standard configurations include 16″ × 18″, 24″ × 18″, 24.5″ × 18.5″, and 24″ × 36″ panels

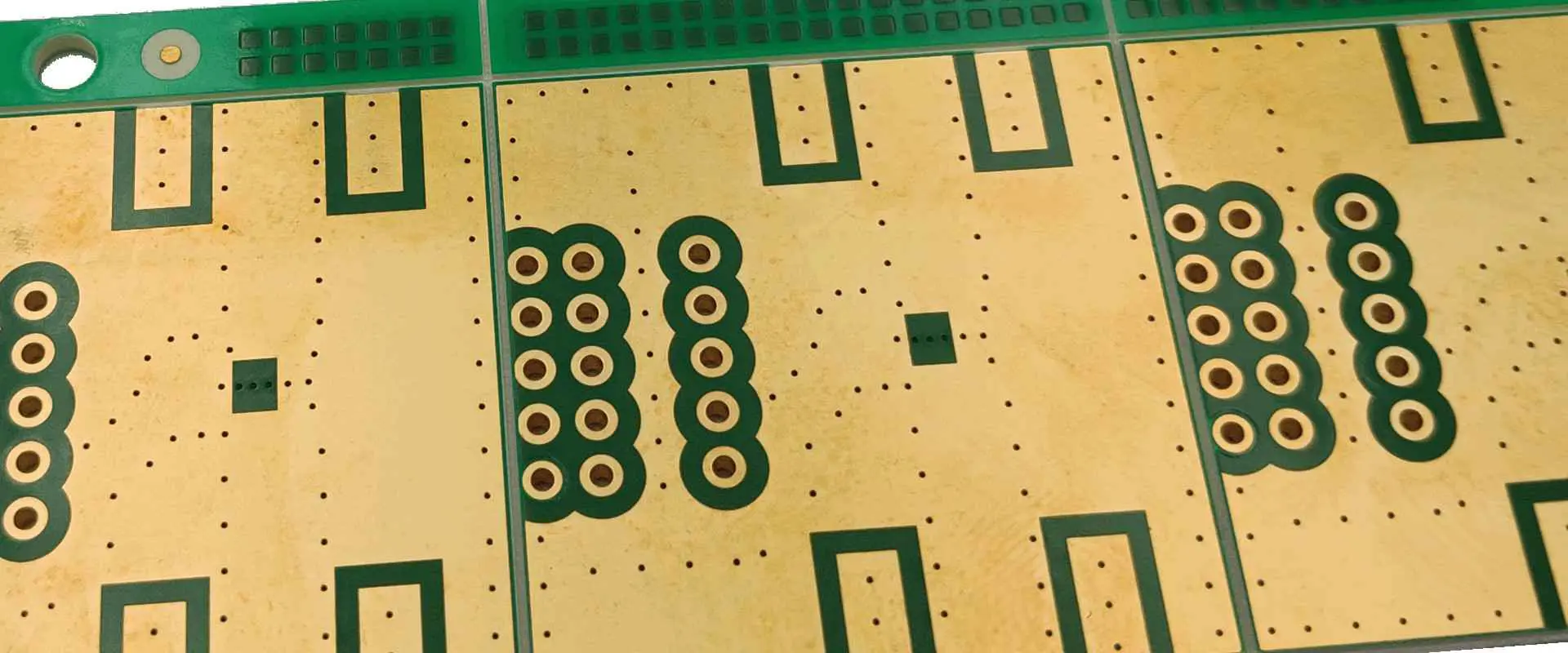

Multilayer Construction Capabilities

RO4450T bonding materials are compatible in multilayer board constructions with RO4003C, RO4350B, RO4835, RO4360G2, and RO4000 LoPro laminates, making them ideal for hybrid constructions that combine high-performance RF layers with cost-effective FR-4 materials.

The material demonstrates excellent CAF (Conductive Anodic Filament) resistance and provides high reliability plated through-hole performance, critical for complex multilayer designs requiring superior electrical and mechanical reliability.

Target Applications

Primary applications include backhaul radios, communications systems, power amplifiers, and small cells/DAS (Distributed Antenna Systems). The material is particularly well-suited for advanced millimeter wave multi-layer designs where consistent electrical performance and thermal reliability are paramount.

Rogers 4450T represents a comprehensive bonding solution that bridges the gap between high-performance RF requirements and manufacturing efficiency, offering designers the flexibility to create sophisticated multilayer constructions while maintaining compatibility with established PCB fabrication processes.