Overview

Our advanced LED PCB manufacturing solutions are specifically engineered to address the critical thermal challenges inherent in high-power LED applications. These specialized printed circuit boards integrate cutting-edge thermal management technologies to ensure optimal LED performance, extended lifespan, and reliable operation across demanding environments.

Key Features

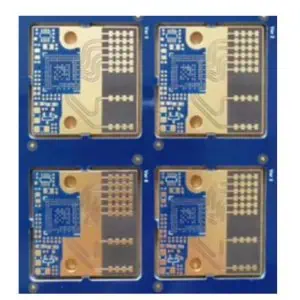

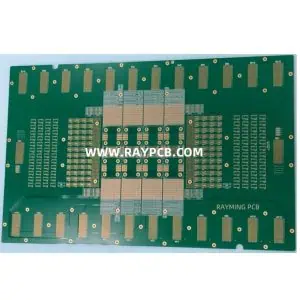

Metal Core PCB (MCPCB) Construction Our LED PCBs utilize aluminum or copper substrates that provide exceptional thermal conductivity, effectively dissipating heat generated by high-power LEDs. The metal core acts as an integrated heat spreader, eliminating hot spots and maintaining uniform temperature distribution across the board.

Thermal Interface Materials Advanced dielectric layers with high thermal conductivity (up to 3.0 W/mK) ensure efficient heat transfer from LED components to the metal substrate while maintaining electrical isolation. These materials are specifically formulated for LED applications, offering long-term reliability and thermal stability.

Optimized Circuit Design Strategic copper trace routing and thermal via placement maximize heat dissipation pathways. Our designs incorporate thermal relief patterns and copper pour techniques that enhance heat spreading while maintaining electrical performance and signal integrity.

Surface Finishes for Heat Dissipation Multiple surface finish options including HASL, ENIG, and OSP are available, each optimized for different thermal and soldering requirements. These finishes ensure excellent thermal contact between components and PCB while providing superior corrosion resistance.

Applications

- Automotive LED lighting systems

- Street and architectural lighting

- High-bay industrial fixtures

- LED displays and signage

- Horticultural grow lights

- Medical and surgical lighting

Thermal Performance Benefits

Our LED PCBs deliver junction temperature reductions of 20-40°C compared to standard FR4 boards, significantly extending LED lifespan and maintaining color consistency. The superior thermal management enables higher power density designs while meeting stringent reliability requirements for commercial and industrial applications.

Manufacturing Capabilities

- Board thickness: 0.8mm to 3.2mm

- Copper weights: 1oz to 6oz

- Substrate materials: Aluminum 5052, Aluminum 6061, Copper

- Size range: 10mm x 10mm to 500mm x 400mm

- Surface finishes: Multiple options available

- Lead times: 5-15 days depending on specifications

Transform your LED lighting projects with our proven thermal management solutions that deliver exceptional performance, reliability, and cost-effectiveness.