Industrial equipment controllers are critical components in modern manufacturing and automation systems, responsible for managing and regulating the operation of machinery, ensuring precision, efficiency, and reliability. The Printed Circuit Board Assembly (PCBA) is the backbone of these controllers, integrating electronic components and circuitry to enable complex control functions. Designing and assembling a PCBA for industrial equipment controllers requires a deep understanding of both electronic engineering and the specific demands of industrial environments.

Design Considerations for Industrial Equipment Controller PCBA

- Environmental Robustness: Industrial environments are often harsh, with exposure to extreme temperatures, humidity, dust, vibrations, and electromagnetic interference (EMI). The PCBA design must incorporate rugged materials and protective measures, such as conformal coating, to ensure durability and longevity.

- High Reliability: Industrial equipment controllers must operate continuously with minimal downtime. The design should prioritize high-reliability components, redundancy, and fail-safe mechanisms to prevent system failures that could disrupt production.

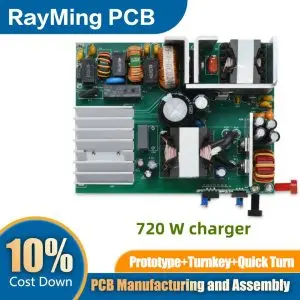

- Power Management: Industrial controllers often require efficient power management to handle varying loads and ensure stable operation. This includes designing robust power supply circuits, voltage regulators, and protection against power surges or fluctuations.

- Signal Integrity: Precision control demands high signal integrity. Careful PCB layout, proper grounding, and shielding are essential to minimize noise and interference, especially in high-frequency applications.

- Thermal Management: Industrial equipment generates significant heat, which can affect the performance and lifespan of electronic components. The PCBA design must include effective thermal management strategies, such as heat sinks, thermal vias, and proper component placement.

- Scalability and Modularity: Industrial systems often require customization and scalability. Modular PCBA designs allow for easy upgrades or modifications, reducing downtime and costs.

- Compliance with Standards: Industrial equipment must comply with industry standards such as ISO, IEC, and UL. The PCBA design must adhere to these regulations to ensure safety, reliability, and market acceptance.

PCBA Assembly Process

- Component Selection: Choosing high-quality, industrial-grade components is crucial. This includes microcontrollers, sensors, connectors, and passive components that can withstand harsh conditions.

- PCB Fabrication: The PCB is fabricated using materials suitable for industrial applications, such as FR-4 with high thermal resistance. Multi-layer boards are often used to accommodate complex circuitry.

- Surface Mount Technology (SMT): SMT is widely used for PCBA assembly due to its precision and efficiency. Automated pick-and-place machines ensure accurate component placement, while reflow soldering creates reliable connections.

- Through-Hole Technology (THT): For components requiring additional mechanical strength, such as connectors or large capacitors, THT is used alongside SMT.

- Inspection and Testing: Rigorous inspection and testing are critical to ensure quality. Automated Optical Inspection (AOI), X-ray inspection, and functional testing verify the integrity and performance of the PCBA.

- Conformal Coating: To protect against environmental factors, a conformal coating is applied to the assembled PCBA. This layer safeguards against moisture, dust, and chemical exposure.

- Final Assembly and Integration: The PCBA is integrated into the industrial equipment controller housing, connected to peripherals, and tested in real-world conditions to ensure seamless operation.