Prototype PCB Assembly: Fast, Reliable, and Affordable Solutions

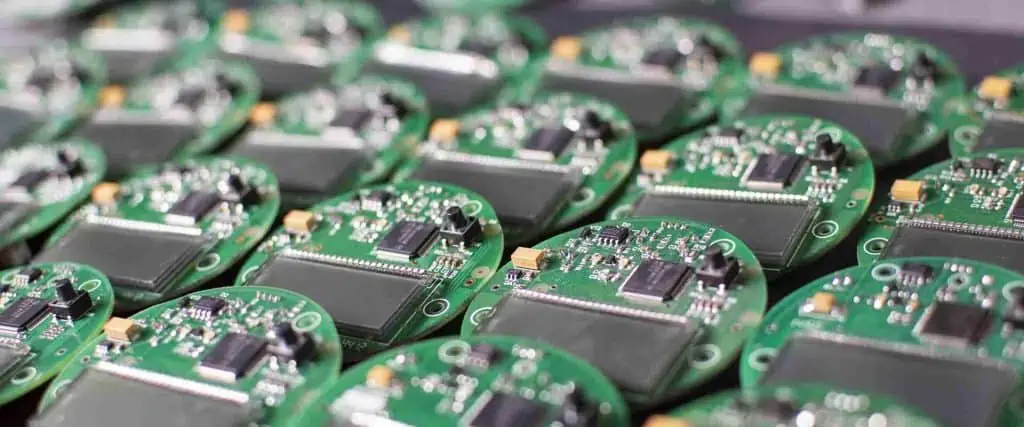

Custom prototype assembly services with rapid turnaround times. We handle small to medium production runs without minimum order requirements.

Introduction: The Critical Role of Prototype PCB Assembly in Modern Electronics

In today’s rapidly evolving electronics industry, the ability to quickly transform innovative concepts into functional prototypes can make the difference between market leadership and playing catch-up. Prototype PCB assembly is the manufacturing process of creating small quantities of printed circuit boards to test and validate electronic designs before full-scale production. This critical service has become the backbone of modern product development, enabling engineers to validate designs, identify potential issues, and optimize performance before committing to expensive mass production runs.

The demand for quick turn prototype PCB assembly has skyrocketed as companies across industries – from consumer electronics to medical devices, automotive systems to aerospace applications – face increasing pressure to reduce time-to-market while maintaining the highest quality standards. Quick Turn PCB Assembly is critically important in the electronics manufacturing industry due to its ability to dramatically shorten development cycles, allowing engineers to iterate faster and bring innovative products to market ahead of competitors.

Understanding Quick Turn Prototype PCB Assembly

What Makes It “Quick Turn”?

A quickturn circuit board is designed, fabricated, assembled, and tested in an extremely short duration. The turnaround time ranges from 24 hours to 7 days based on the design complexity. This accelerated timeline is achieved through streamlined processes, dedicated prototype production lines, and strategic partnerships between PCB fabricators and assembly houses.

The quick turn approach differs significantly from traditional PCB manufacturing, which prioritizes high-volume efficiency over speed. Quick turn services focus on flexibility, rapid setup changes, and the ability to handle small quantities efficiently. Simple boards can be turned around next day, but more complex printed circuit boards will likely need longer lead times. Prototype assemblies that can be hand soldered will have quicker turnarounds compared to assemblies that need stencils, SMT programming, and tooling.

Key Components of the Process

The prototype PCB assembly process encompasses several critical stages:

Design for Manufacturing (DFM) Analysis: Before production begins, experienced engineers review design files to identify potential assembly challenges. Professional services perform Design for Manufacturing (DFM) analysis to identify potential assembly issues before production begins. This proactive approach prevents costly delays and ensures optimal manufacturability.

Component Procurement: Quick turn services maintain extensive inventories of common components and leverage established relationships with distributors. Our procurement team possesses an in-depth understanding of diverse project requirements, enabling them to work effectively with these suppliers.

Assembly and Testing: Using both automated surface mount technology (SMT) and through-hole assembly techniques, prototypes are built to production standards. Whether it is a quick turn PCB assembly or a full volume production run, the PCBs undergo rigorous testing and inspection.

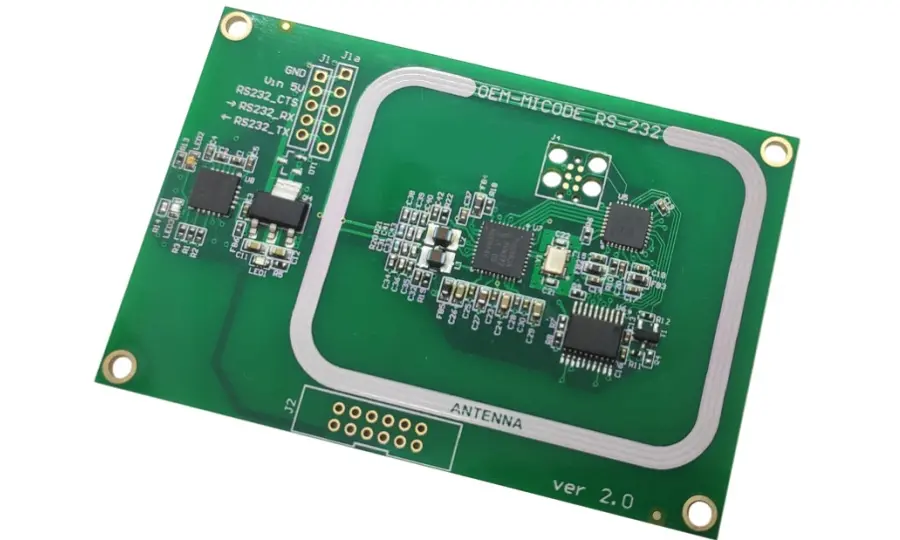

Prototype PCBA We Served

Computer Motherboard PCBA

Communication Module PCBA

Smartphone PCBA Prototyping

The Speed Advantage: How Fast Can You Go?

Industry-Leading Turnaround Times

The most competitive quick turn prototype PCB assembly services now offer unprecedented speed:

- 24-Hour Service: Sierra Assembly can easily fulfill your quick turn PCB assembly needs. We are known to provide the shortest turnaround times in the industry, with lead times starting from just 24 hours for simple designs.

- Same-Day Options: Generally, we provide on the same day, or in 24 hours, 3 days, and 5 days turnaround times for PCB prototyping.

- Standard Quick Turn: Most providers offer 3-5 day standard quick turn services for more complex assemblies.

Factors Affecting Turnaround Time

Several key factors influence how quickly your prototype can be completed:

Design Complexity: As circuit board assemblies get more complex (higher number of copper layers and component counts), the number of processes increase. High-density interconnect (HDI) boards, multiple lamination cycles, and advanced via structures require additional processing time.

Component Availability: If we are sourcing components, and you are looking for a quick turnaround, one component that has a 12 week lead time is likely a show stopper. Smart planning and component selection are crucial for achieving the fastest turnarounds.

Assembly Method: Hand assembly for low quantities versus automated SMT lines for higher volumes affects both speed and cost. Projects will be soldered manually or by pick-n-place machines, depends on the project’s quantity and soldering difficulty.

Reliability Standards: IPC Compliance and Quality Assurance

IPC Standards: The Foundation of Quality

Reliable prototype PCB assembly requires adherence to established industry standards. IPC standards are critical for producing quality PCBs, providing comprehensive guidelines for design, manufacturing, and assembly processes.

IPC Classification System: Class 1 assemblies are indicative of general products, also called consumer-level electronics. Class 2 assemblies represent stricter manufacturing tolerances and design constraints. Electronics in this class are designated dedicated service products. Class 3 represents the highest reliability requirements for mission-critical applications.

Key Standards for Assembly:

- IPC-A-610: IPC-A-610 is one of the most widely used standards in the electronics industry. It provides visual acceptance criteria for electronic assemblies and is often referred to as the “bible” of the industry

- IPC-J-STD-001: Covers soldering requirements and materials specifications

- IPC-A-600: Defines acceptability criteria for bare printed circuit boards

Quality Control Measures

Leading prototype assembly providers implement comprehensive quality control:

Automated Optical Inspection (AOI): Green Circuits’ AOI process ensures precision and quality in PCB assembly by using high-resolution cameras to detect soldering errors, missing components, and misalignments.

X-Ray Inspection: Essential for inspecting hidden solder joints under BGA and QFN components.

In-Circuit Testing (ICT): Verifies electrical connectivity and component values.

Functional Testing: Makerfabs help to test all the PCBA to ensure you 100% pass, confirming that assembled boards perform according to specifications.

Cost-Effectiveness: Making Prototypes Affordable

Understanding Prototype Assembly Pricing

PCB assembly costs can range from a mere $0.02 to over $50 per board, with dramatic variations based on complexity, volume, and requirements. Understanding the cost structure helps optimize budgets:

Setup Costs: A lot of PCBA cost is in NRE (non-recurring engineering). They have to set up equipment on the line whether the ordered quantity is 1 or 10k. These one-time costs include stencil fabrication, programming, and line setup.

Component Costs: Typically the largest portion of total cost, including both component prices and procurement fees.

Assembly Labor: PCB assembly usually costs between $0.02 and $0.05/square inch. However, this estimate is based on several factors, including labor and overhead expenses.

Cost Optimization Strategies

Volume Considerations: The assembly pricing can be quite deceiving when in smaller quantities. The total assembly cost for prototype boards may seem much less when compared to the total cost of boards when manufactured in larger quantities. But one thing that people fail to notice is that the unit price of assembly drops down to a very large extent when produced in large quantities.

Geographic Factors: A board assembled in North America will be 3 to 4 times more expensive compared to one assembled in Asia because of the availability of cheap and skilled labour.

Design Optimization: Simplifying designs, using standard components, and optimizing for manufacturability can significantly reduce costs.

Affordable Options Without Compromise

Modern prototype assembly services offer various pricing models:

Special Promotions: ALLPCB has recently launched a special $1 campaign. This campaign is designed to help makers, startups, and hardware developers reduce custom PCB board cost at the earliest stage of product development.

Open Parts Libraries: The PCBA Open Parts Libraries (OPL) are a catalog of over 150,000 locally in-stock parts designed to simplify and slash the PCBA procurement time. Source all parts from the OPLs to cut the production time to just 7 working days.

Technical Capabilities: Advanced Assembly Technologies

Surface Mount Technology (SMT) Excellence

Modern prototype assembly facilities offer advanced SMT capabilities:

Component Size Range: Our SMT factory has the capacity to handle BGA, QFN, CSP, LGA, 0201, 01005, accommodating the smallest components available in the market.

Precision Placement: GreatPCB specializes in assembling multi-layer PCBs with fine traces and spaces, flex-rigid PCBs, and boards with 0201 components and microBGAs.

High-Density Boards: Our staff is qualified and experienced in managing fine-pitch parts and ball grid arrays (BGAs) for high-density FR-4 PCBs.

Mixed Technology Assembly

Through-Hole and SMT Combination: Many prototypes require both technologies. SMT Assembly, BGA Assembly, Through-Hole Assembly, Mixed Assembly, Rigid Flex PCB Assembly Services are all available from comprehensive service providers.

Flexible Manufacturing: Our prototype assembly line has a unique layout design that allows a flexible combination of automated and manual components loading stations.

Industry Applications and Use Cases

Consumer Electronics

The consumer electronics industry is one of the most fiercely and dynamically competitive markets today. Quick turn prototype assembly enables rapid iteration for smartphones, tablets, wearables, and smart home devices.

Internet of Things (IoT)

As the IoT industry develops, there is an increasing need for PCBs; as new Internet of Things are introduced to homes, industries, and even cities. Prototype assembly supports the development of connected devices requiring both functionality and cost-effectiveness.

Medical Devices

Medical applications demand the highest reliability standards. Whether it’s a pacemaker or a military radar, a product that needs to meet IPC Class 3 requirements must use high-reliability electronic components to ensure uninterrupted service.

Automotive Electronics

Modern vehicles are becoming increasingly reliant on electronic systems for everything from infotainment to engine control. This creates a significant demand for reliable PCBs that can be produced at a reasonable cost.

Choosing the Right Prototype Assembly Partner

Key Selection Criteria

Technical Expertise: Look for providers with demonstrated experience in your specific technology requirements. Evaluate potential providers based on their technical expertise: Component handling: Fine-pitch BGAs, micro-components, odd-form parts.

Quality Certifications: We are committed to quality therefore our assemblies are built in compliance with IPC-A-610-D and ANSI/J-STD-001, Class II, and Class III standards.

Turnaround Capabilities: We offer 1-day, 2-day, and 5-day quick turnaround PCB assembly, and 1-day fast turnaround PCB prototype manufacturing services.

Location Considerations

Location is a critical factor when it comes to prototyping efforts. Opting for a local CM can be an advantage in quickturn services. Consider the trade-offs between cost, speed, and communication when choosing between domestic and overseas providers.

Future Trends in Quick Turn Assembly

Automation and AI Integration

The integration of artificial intelligence in PCB assembly processes is predicted to reduce costs by up to 20% by 2026. AI can optimize component placement, reduce errors, and increase overall efficiency.

Advanced Materials and Technologies

3D printing technology for PCBs could revolutionize prototyping costs. By 2025, we may see more accessible and affordable 3D-printed PCB options for rapid prototyping.

Sustainability Focus

As the electronics industry focuses more on sustainability, we may see the introduction of more eco-friendly PCB materials, driving innovation in both materials and processes.

Best Practices for Prototype Assembly Success

Design Preparation

Complete Documentation: Ensure all design files, BOMs, and assembly drawings are complete and accurate. If we are sourcing components, we need BOMs to have complete manufacturer part numbers.

Component Selection: Choose readily available components when possible to avoid delays. Help us know what our options are a head of time. For example, identify the hard to find components and let us know that you plan on supplying them or that we can Do Not Install (DNI) specific components.

Communication and Project Management

Clear Requirements: Specify testing requirements, quality standards, and delivery expectations upfront.

Regular Updates: Makerfabs will keep the customer in touch in the whole process of production, or customers can check with the project manager anytime.

Conclusion: The Strategic Advantage of Quick Turn Prototype Assembly

Quick turn prototype PCB assembly has evolved from a luxury service for urgent projects to an essential capability for competitive product development. By providing rapid production of printed circuit boards, this service allows to quickly prototype, test, and refine their designs, accelerating the time-to-market for new electronic products.

The combination of speed, reliability, and affordability offered by today’s leading prototype assembly services empowers engineers and companies to innovate faster, reduce development risks, and bring higher-quality products to market. Whether you’re a startup with your first prototype or an established company developing next-generation products, choosing the right quick turn assembly partner is crucial for success.

As the electronics industry continues to evolve at breakneck speed, those who leverage quick turn prototype assembly effectively will maintain their competitive edge, turning innovative concepts into market-ready products faster than ever before. The future belongs to those who can prototype quickly, iterate rapidly, and scale efficiently – and quick turn prototype PCB assembly is the key that unlocks this potential.

Ready to accelerate your next electronics project? Partner with a proven quick turn prototype PCB assembly provider and experience the speed, reliability, and affordability that drives innovation forward.

FAQs:

1. How long does prototype PCB assembly take?

Prototype PCB assembly turnaround times vary based on complexity and service level. Standard prototype assembly typically takes 5-10 business days from file submission to delivery. Express services can deliver prototypes in 24-72 hours for urgent projects, while economy options may take 10-15 business days. Factors affecting timeline include component availability, board complexity, testing requirements, and current production schedules.

2. What’s the minimum order quantity for prototype PCB assembly?

Most professional prototype PCB assembly services offer no minimum order quantity (MOQ), allowing you to order even a single prototype board. This flexibility is ideal for proof-of-concept testing, design validation, or one-off projects. While single board orders are possible, ordering 5-10 prototypes often provides better value per unit and allows for multiple testing scenarios.

3. How much does prototype PCB assembly cost?

Prototype PCB assembly costs depend on several factors including board complexity, component count, assembly type (SMT vs through-hole), and testing requirements. Simple prototypes typically start around $300-500 for setup and labor plus component costs, while complex designs with fine-pitch components or extensive testing can cost several thousand dollars. Most services provide instant online quotes based on your uploaded files and specifications.

4. What files do I need to provide for prototype PCB assembly?

Essential files for prototype PCB assembly include Gerber files (for PCB fabrication), a detailed Bill of Materials (BOM) with manufacturer part numbers, pick and place files (centroid/XY data), and assembly drawings with special instructions. Additional helpful files include netlist files, 3D models, test specifications, and fabrication notes. Professional services will review your files and request any missing information before starting assembly.

5. Can I provide my own components for prototype PCB assembly?

Yes, most prototype assembly services offer consigned component options where you provide some or all required parts. This approach can be beneficial when you have specific component preferences, already purchased parts, or need to use components from approved vendor lists. When providing components, ensure they’re properly packaged in anti-static materials, clearly labeled with reference designators, and include extras for potential assembly losses.