Our advanced ultrasound printed circuit boards deliver exceptional performance for medical imaging applications, engineered to meet the demanding requirements of modern diagnostic equipment. These specialized PCBs form the critical electronic backbone of ultrasound systems, enabling precise signal processing and superior image quality.

Key Features:

- High-frequency signal processing capabilities up to 20MHz for optimal image resolution

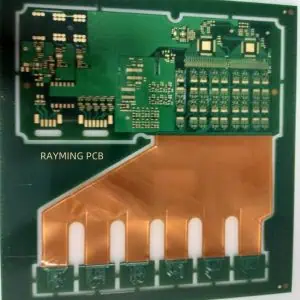

- Multi-layer construction with controlled impedance design for minimal signal degradation

- Low-noise analog front-end circuits for enhanced sensitivity and dynamic range

- Integrated beamforming electronics supporting phased array transducer configurations

- EMI/RFI shielding compliance for medical device electromagnetic compatibility

- Temperature-stable components rated for continuous medical equipment operation

Technical Specifications:

- Supports 64-256 channel configurations for advanced imaging modes

- Signal-to-noise ratio exceeding 60dB for clear diagnostic images

- Real-time processing capabilities for Doppler and 3D/4D imaging

- Medical-grade PCB materials meeting IPC-6012 Class 3 standards

- RoHS compliant lead-free manufacturing processes

Applications:

- Diagnostic ultrasound systems (abdominal, cardiac, obstetric, vascular)

- Portable and handheld ultrasound devices

- Point-of-care ultrasound equipment

- Veterinary ultrasound systems

- Industrial non-destructive testing applications

Quality Assurance: Each PCB undergoes rigorous testing including automated optical inspection, in-circuit testing, and functional verification to ensure reliable performance in critical medical environments. Our manufacturing processes are ISO 13485 certified and FDA-compliant for medical device components.

Designed for seamless integration with leading ultrasound transducers and imaging software platforms, these PCBs provide the foundation for next-generation medical imaging solutions with exceptional reliability and diagnostic accuracy.