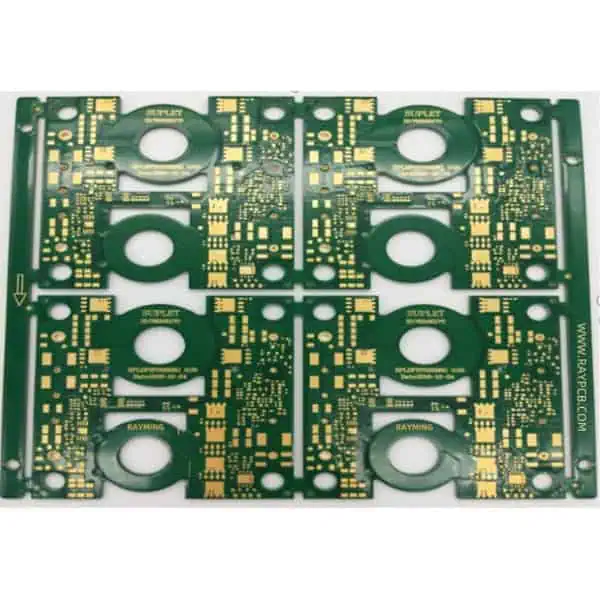

Engineered for High-Power Applications with Superior Current Handling

Our Thick Copper PCBs deliver exceptional current-carrying capacity and thermal performance for demanding electronic applications. Featuring copper weights ranging from 2oz to 10oz (70μm to 350μm), these boards are specifically designed to handle high-current loads while maintaining signal integrity and reliability.

Key Features

Enhanced Current Capacity: Heavy copper construction provides significantly higher current-carrying capability compared to standard PCBs, supporting applications requiring substantial power delivery without voltage drop or excessive heating.

Superior Thermal Management: The increased copper mass acts as an effective heat spreader, dissipating thermal energy across the board surface and reducing hot spots that can compromise component performance and longevity.

Robust Construction: Multiple copper weight options (2oz, 3oz, 4oz, 6oz, 8oz, 10oz) allow for customized current handling based on your specific application requirements, from moderate power designs to extreme high-current systems.

Versatile Applications: Ideal for power supplies, motor controllers, LED lighting systems, automotive electronics, industrial equipment, and any application where current density exceeds standard PCB capabilities.

Technical Advantages

The thick copper construction enables wider trace widths without increasing board real estate, while the enhanced copper thickness provides lower resistance paths for current flow. This combination results in improved efficiency, reduced power loss, and enhanced overall system reliability. The boards maintain excellent plating adhesion and via reliability even with heavy copper weights.

Quality Assurance

Manufactured to IPC standards with rigorous quality control processes, ensuring consistent copper thickness, proper layer adhesion, and reliable electrical performance across all production batches.

Transform your high-power designs with PCBs built to handle the current your applications demand.